Before we get to the actual topic of this article, it must be stated that technically, OHC (Overhead Camshaft) engines are also OHV (Overhead Valve) engines, since the valves in these engines are also located in the cylinder head(s). Thus, to avoid confusion, this article will use the term “OHV” to refer to engines that use pushrods to activate the valves, as opposed to being activated by camshafts that are located in the cylinder head(s).

Nonetheless, in a world that is dominated by high-tech OHC engine designs, OHV engines are often derided as being outdated, antiquated, or simply as anachronistic, but the fact is that hundreds of thousands of OHV engines are still being produced by General Motors, one of the worlds’ leading car manufacturers. Moreover, OHV engines still dominate in NASCAR, one of the worlds’ premier motor sports disciplines, which means that OHV engines must have a lot going for them. In this article, we will take a closer look at some of the reasons why OHV engines not only exist, but have a large and loyal following despite also having serious drawbacks and disadvantages, starting with the fact that-

In the context of car engines, “size” refers to the overall outside dimensions of an engine, and while this may not mean much in the lives of most technicians, making an engine as small and light as possible is a big deal in the lives of some car designers.

However, while some readers may find a comparative list of engine dimensions interesting, such a list does not explain the practical advantages of OHV engines over OHC engines, one of which is the fact the LS-series of engines (made by General Motors) are all smaller than OHC engines of similar, or even larger displacements made by competing manufacturers. In fact, the LS1 V8 engine is the smallest of all V8 engines available today.

Having a smaller engine allows car designers to tweak design imperatives like weight distribution and the centre of gravity much more easily. For instance, since the LS-series engines used in the Corvette C6 as well as the LT-series engines used in the Corvette C7 are all about 100 mm less tall than similar displacement engines in competing brands, the centre of gravity of Corvettes is significantly lower than it is in competing cars that use OHC engines.

Moreover, also being shorter than most OHC engines, LS and LT series engines can be placed further back from the front axle line, which greatly improves the distribution of weight between the front and rear axles. In combination, the lower centre of gravity and improved weight distribution makes for improved brake and steering responses, which is a huge advantage in a highly competitive segment of the market.

One of the greatest advantages of OHV engines over OHC engines is their mechanical simplicity, which not only reduces manufacturing costs, but maintenance costs as well.

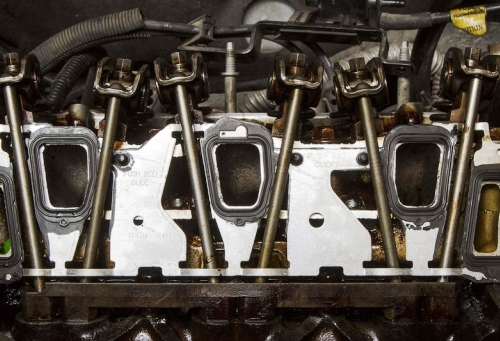

In practice, the single camshaft of an OHV V-type engine is located in the empty space between the two cylinder banks, which means that the camshaft can be driven from the crankshaft with a single and usually very short chain, or with a simple gear drive. The practical advantage of this is that there are fewer things than can go wrong, typical examples being timing chain tensioners, guides and sprockets that wear out, timing chains that “stretch” due to wear of chain rollers and bushes, timing belts that wear out and/or break, and timing belts and tensioners that require regular replacement.

From our perspective as technicians, these are not necessarily bad things since repairing these issues translate into paid work, but from the perspective of the average car owner, the reduced maintenance costs that come with OHV engines is huge bonus.

While this is indisputably true, it is so only up to a point, this point in an OHV engines’ operating range being where two valves per cylinder can no longer supply the cylinders with enough air, fast enough.

Here is what happens: when an OHV engines’ pistons are on the intake stroke, the single intake valve’s diameter effectively forms a restriction in the intake system that accelerates the airflow through the intake runner, much like a narrow spot in an otherwise wide riverbed accelerates the river’s rate of flow through the narrow spot.

Thus, by matching the intake valve’s lift and duration to the accelerated airflow at low(er) engine speeds by means of purpose-designed cam profiles, more air and fuel can be forced into the cylinders than is possible to do through the combined diameters of two intake valves on OHC engines, even though the effective combined diameters of two or sometimes three smaller intake valves may sometimes be bigger than that of a single intake valve on an OHV engine.

Generally, the practical effect of matching an OHV engines’ intake valve lift and duration to an accelerated airflow is that OHV engines make more power at low(er) engine speeds than OHC engines make at comparable engine speeds. Of course, this largely applies only to naturally aspirated engines, and the differences in power delivery between OHC and OHV engines at lower engine speeds depend on many variables, including displacement, fuel used, and whether or not both engines are running on standard engine and fuel management settings.

Those among us who routinely encounter camshaft timing or phasing issues on OHC engines caused by dirty and/or degraded oil are perhaps better able to understand the advantages of a simplified lubrication system than those who have not spent hours trying to clear blockages and restrictions from convoluted oil passages in OHC cylinder heads.

As a practical matter, since OHV engines do not have camshafts in their cylinder heads that need to be fed with pressurized oil, the pushrods in these engines are used to transport oil to the rockers and rocker shafts. Moreover, since the camshaft in an OHV engine is located in the engine block, the same oil circulation system that supplies the crankshaft bearings with oil is used to lubricate the camshaft as well. A further advantage of this is that a smaller capacity oil pump can be used, which in turn leads to a reduction in parasitic power losses since a smaller, low capacity oil pump is easier to spin than a large, high capacity oil pump.

Of course, the above title should really read as follows; OHV engines can exhibit better driveability than comparable OHC engines (in terms of displacement), but only up to engine speeds of about 3000 RPM, and only if the OHC engine has not been modified or tuned to produce more low-end torque than a similar OHC engine.

This statement is quite a mouthful and assumes much, but also assuming that both engines are in standard trim, at low engine speeds the OHV engine will make more power than the OHC engine will. This is because the OHV engine has a better volumetric efficiency at low engine speeds, thus producing more power through improved combustion, which necessarily produces more power and hence, more torque.

However, at this point it may be beneficial to explain the differences between power and torque as a means to explain why an OHV engine can have superior driveability characteristics, starting with-

Power

Power is a measurement of how much work can be done in a given period. In some markets this measure is expressed as horsepower, which is equal to 33 000 pounds being lifted one foot in one minute. In the SI standard, the equivalent measure is the kilowatt.

Torque

Torque is a measurement of a rotating force; torque being the result of force multiplied by distance, such as the forces a piston exerts on a crankshaft multiplied by the crankshafts’ stroke. Torque always moves in a certain direction, and it is expressed as Newton-metres in the SI standard.

Since an OHV engine makes more power at low engine speeds than a comparable OHC engine, it will continue to make more power as the engine speed increases, and hence, produce more torque, until it reaches the point where the volumetric efficiency of the OHV engine is overtaken by that of the OHC engine.

However, about 3 000 RPM of a large displacement V8 OHV engine represents road speeds that are well in excess of urban speed limits, which largely makes comparisons of drivability characteristics between OHV and OHC engines above legal speed limits moot. Nonetheless, since an OHV engine produces more power at low engine speeds, it has an increased capacity to perform work at low engine speeds, i.e., to overcome the vehicles’ inertia sooner. In practice, this translates into higher rates of acceleration at lower engine speeds, which in turn, translates into superior driveability characteristics at low speeds.

While OHV engines suffer from serious drawbacks such as a limited operating range as compared to OHC engines that can rev to beyond 7 000 RPM, reduced volumetric efficiencies at engine speeds above about 3 000 RPM, and a higher reciprocating mass than OHC engines, OHV engines remain a popular choice among car buyers and performance engine builders alike, largely because GM has managed to iron out all the bugs from the OHV design.

One other major criticism of OHV engines has been the fact that VVT or VCT technologies cannot be implemented on them, but this issue has been successfully overcome with the invention of variable valve technology on the 447 kW SRT-10 OHV engine that was first used in the 2008 iteration of the Dodge Viper. Dodge named this system “CamInCam”, and it is capable of phasing the intake and exhaust valves independently of each other, which places this engine among the most advanced OHC engines designs in terms of performance and power delivery throughout its operating range.

In addition, the Chrysler 5.7L OHV Hemi engine that was first released in 2002 featured variable displacement technology, and as a result, featured on Ward’s 10 Best Engines list from 2003 to 2007, which if nothing else, proves that OHV engines can be as far from archaic as it is possible to get.