Although it is not exactly clear who first defined “insanity” as “...doing the same things over and over and expecting different results each time”, this writer is certain that it was a mechanic. In particular, by a mechanic who was dealing with a diagnostic process that refused to yield the desired results for reasons that remained unclear to the mechanic. We have all fought such battles, but this writer recently fought one that lasted for several days, during which time his patience was severely tested, and his staff began to question his sanity. This is the story of that battle, but let us start with stating-

The problem arrived on the back of a recovery truck, in the form of a 2006 Chrysler 300 LX with a 5.7L Hemi engine. The driver of the truck could not tell us anything about the vehicle, except that he was asked to pick up the vehicle at the owner's home and to deliver it to us, which he did along with a note in an envelope.

Reading the note, it turned out that the vehicle belonged to a regular customer who recently bought the vehicle from a deceased estate. The note also stated that the vehicle had been running perfectly, but had developed severe driveability issues over the past month or so. The note further stated that when the symptoms first appeared, they did so sporadically, and without a definite pattern until they had progressed to the point where the car could not be driven. The note ended with some cryptic descriptions of the symptoms, and for the sake of clarity, we will reproduce those descriptions verbatim-

The note started with saying that “...car drives rough, and is jerking all the time- worse in wet weather. Engine shuts off sometimes at stop signs and traffic lights. Starts again sometimes but not always. Engine not running all cylinders all the time- although spark plugs replaced ten days ago, but worse now than ever. Sometimes get random misfire codes with phone app. (Italics added)

As a parting shot, the vehicle owner’s cryptic note stated that he would be travelling for the next three weeks, and so could we please fix the problem and store the vehicle until he gets back?

Of course, the right thing to do would have been to wait for the vehicle’s owner so we could get more information on the problem, but since this customer was a regular who for many years had always paid his repair bills without ever questioning anything, we accepted the challenge and started with-

Although the vehicle seemed to be in decent shape despite the 249 000km shown on the speedometer, it was obvious that someone else had been working on the vehicle shortly before, since the cosmetic engine cover was missing and one retaining screw was missing from each of two ignition coils.

Nonetheless, we decided to see what would happen if we tried to start the engine. The engine did start but the starter motor dragged noticeably, and the intake system had a distinctly “whooshy” sound, which as it turned out, was caused by a missing air filter element. There was also some tappet noise, and the idling was a little rough but that went away after a bit. There was no smoke, fire, or other serious mechanical noises, and going by appearances the engine looked to be in a reasonable condition, fluid-leak wise.

Thus emboldened by the facts that a) the Chrysler’s Hemi engine could be started, and b), that the engine ran without noticeable misfires, this writer instructed a service writer to initiate a repair order, and rather unwisely (as it turned out later) allocated the job to himself, turned off the engine, and continued with the preliminary inspection. This is the first issue he found-

Image source: https://www.searchautoparts.com/sites/www.searchautoparts.com/files/images/el-ma1118-mag6.jpg

This is an actual image of the corrosion on one ground connection in the boot, a short distance from the battery. Now, we know that poor ground connections can cause all manner of driveability issues, but we also know that a poor ground connection almost invariably causes a cable termination to heat up, but in this case, there was no evidence of this. Nonetheless, this writer checked all other ground connections and while some were less than perfect, none showed signs of arcing and/or overheating, which should have told him something, but the significance of the lack of overheating did not register with him at the time.

Thus, suspecting a significant voltage drop between the battery and the starter motor to be the cause of the dragging starter, this writer cleaned all ground connections, and made double sure they were tight. He also checked the condition of the battery with a diagnostic charger, and while the battery turned out to be fully charged and in excellent condition, the starter still dragged when the engine was started again. Running jumper cables between the battery and the starter motor eliminated the dragging, so the problem with the starter motor seemed to be wiring related.

However, checking the wiring, or as much of it as could be accessed without ripping the car apart, as well as all known fuse boxes and the starter motor with a thermal heat imager produced no unduly hot spots/areas, so the wiring and starter motor seemed to be OK- despite the obvious dragging. Thus, with no obvious issues being apparent or visible it was time to bring out the big guns, so this writer hauled out and connected his Chrysler-specific wiTech scan tool, which produced some-

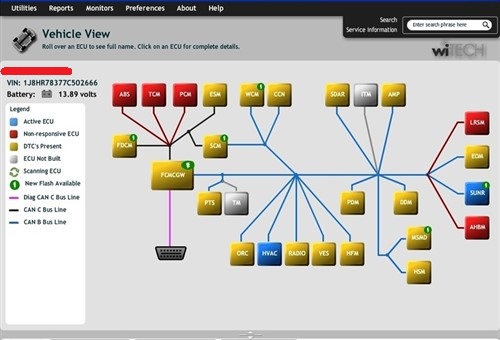

Image source: http://www.autotechonwheels.com/images/2011/06jun/topology-03.jpg

Although this is not a reproduction of the actual display screen, this example shows how wiTech tools display the relationships between all the major control modules on the CAN bus system. On the display of the problem Chrysler, the PCM, TCM, and ABS modules were also shown in red, and according to the legend on the left of the screen, the control modules in red are not communicating over the CAN system.

This was a little surprising to say the least, since if the PCM was not communicating over the CAN system, the engine simply would not start, even though it demonstrably did. Moreover, except for a pending catalytic converter efficiency code, there were no other codes of any sort stored- neither historical nor active and/or pending codes.

Based on the described symptoms, this writer expected to see at least some misfire codes, along with fuel/air metering and likely, one or more cam/crank correlation codes. This lack of trouble codes prompted an interrogation of all major control modules on an individual basis, but since this also failed to produce any fault codes stored anywhere, it was decided to take the vehicle on a test drive to experience the symptoms first-hand. This is what we found on-

Leaving the scan tool connected to record ignition data via the crankshaft position sensor, this writer and the workshop’s resident diagnostician embarked on the test drive, which started smoothly enough. There were no signs of misfiring or other issues, but this changed suddenly, and in dramatic fashion, the moment the transmission shifted up into second gear. There was a wild bucking, some loud thudding noises, followed by a severe surge- all of which disappeared as suddenly as it began. Things settled down, but the same symptoms reappeared when the transmission shifted into third gear after a gentle acceleration. Only this time, the bucking and surging were both noticeably worse than before, and although the engine stalled a few seconds after the symptoms appeared the second time we could start it again almost immediately, and to prevent a recurrence of the symptoms, we limped back to the workshop at idling speed.

Thinking we had collected at least some useable data, we found that instead of useable data, the scan tool did not record anything at all. In addition, a subsequent scan again showed a non-communicative PCM and no stored fault codes. Repeating the test drive produced identical results, which initiated-

At this point, you may very well suggest that we check the basics first. Things like the integrity, performance, and resistances of the ignition coils. Alternatively, we might perhaps verify the signal outputs and correlation of the cam/crank position sensors. Then again, you might say that we'd do well to verify that the correct sparkplugs had been fitted, or even that we verify base ignition timing settings against peak compression pressures with a pressure transducer and an oscilloscope.

To make a long story short, all of the above are good suggestions but we did all of those tests, and yet, the problem persisted. We also used the wiTech tool to produce wiring diagrams and pin-out charts and spent several days verifying resistances, continuity, and ground integrity in hundreds of circuits, and across dozens of connectors, fuses, and splice joints against OEM service information, and still the problem persisted. On day four, we collectively concluded that since it was clear that the problem was related to the engine load, it was a waste of time continuing wiring tests with the stationary vehicle.

What we now needed to do was to confirm or eliminate the PCM as the root cause of the problem. However, since it was not communicating with the scan tool, we needed or hook up a digital storage oscilloscope to test the communications between the PCM and the TCM with the engine under load, since the TCM plays a major role in engine management. We also needed to test the ignition driver circuits while the engine was under load, but did not want to risk causing a traffic accident if the engine unexpectedly stalled again.

We have done similar tests before by placing problem vehicles on a dynamometer, but as it turned out, the local dynamometer operator was unable to assist us in this matter since his equipment was undergoing major repairs. Our next port of call was the local ECU repair specialists, but since we could not house the vehicle for the four weeks or so it would take them to get around to our problem PCM, we did the next best thing, which was to order a replacement (remanufactured) PCM from the local Chrysler dealership, which arrived the next day. Here’s what happened next-

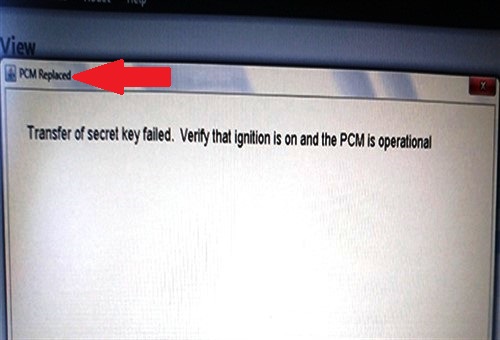

By the time the replacement PCM arrived, we had already spent far too many man-hours on this Chrysler, but having spent so much time already, there was nothing for it but to install the new PCM and get the nightmare out of our lives. Therefore, we attempted just that, but the first attempt at programming the new PCM produced this error message-

Image source: https://www.searchautoparts.com/sites/www.searchautoparts.com/files/images/el-ma1118-mag9.jpg

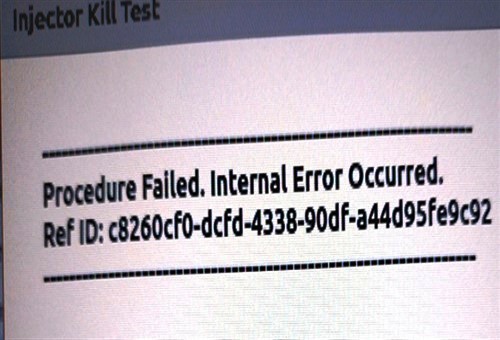

This was rather surprising, so we checked that we had the latest software from an official source and that it contained all the latest patches, fixes, and updates. We also spent several hours scouring the internet for TSB's relating to issues with programming new Chrysler PCM's but came up empty. We also checked that the battery was fully charged and that our clean power supply was working as intended. Everything checked out, but our second attempt at programming the PCM immediately produced this error message-

Image source: https://www.searchautoparts.com/sites/www.searchautoparts.com/files/images/el-ma1118-mag10.jpg

This message was not only surprising- it was infuriating as well since by this time there was no way we could charge the customer for all of the time we had spent chasing ghosts. We were going to take a huge financial hit on this job, but at the same time, we could not just give up and refer the vehicle to a competitor, who for all we knew, could fix the problem in two minutes simply because we were missing something, or worse, were blinded by tunnel vision.

Just as we were considering our next step, an apprentice floated the idea that the replacement PCM might also be defective, since it was a remanufactured unit, after all. The word “also” finally made the penny drop. We should have realised when our first online search did not turn up any TSB’s that addressed the original problem that we were dealing with a PCM that failed in a way that we did not understand. Our experience of Chrysler PCM's hinged on the fact that they either worked or did not work. We have never encountered a Chrysler PCM that only worked half-way, so if both the original and the replacement PCM’s were defective in some way, we spent several days looking for the cause of the problem in all the wrong places, which brings us to-

We returned the (presumed) defective PCM to the dealership and insisted that they replace it with a brand new unit. We were perfectly willing to absorb the additional cost, so when it arrived a few days later we installed it, and it accepted our software without issues or problems of any kind.

We also performed all the required system/component integrations and rewarded the perceptive apprentice by allowing him to undertake the first test drive with the new PCM. However, just to make him understand that he was still an apprentice, albeit a senior apprentice, we hooked up an oscilloscope to monitor and record communications between the PCM and TCM, just in case he missed a small miscommunication between the two control modules.

The starter motor did not drag at all when we first started the vehicle with the new PCM, and live data recorded over several test drives showed that the problem had been resolved definitively. Several scans also showed that all control modules were functioning correctly, and while we were relieved that the Chrysler now ran as smoothly as a proverbial Swiss watch, there was nevertheless a sense in the workshop that both this writer and his resident diagnostician had failed an important test. We were supposed to be the experts after all, so why did we second-guess ourselves so many times during this diagnostic nightmare?

Were we both suffering from information overload? Did neither of us know this particular vehicle well enough not to recognise a failed PCM, or this particular PCM failure mode? Did we simply interpret the customer’s cryptic note incorrectly? Should we have connected the dots between a non-communicative PCM and the lack of fault codes sooner, even though the engine started and ran, albeit badly when under load, with a PCM that seemingly did not communicate?

More importantly, though, did we satisfy the definition of insanity? Perhaps, but what do you think?