Choosing the correct disc brake setup for a fun day at the track can often be confusing and expensive if you use a product not fit for the purpose.

The aftermarket disc brake industry is very competitive and full of confusing sales hype and marketing to attract the buyer.

Unfortunately, “BLING” can very quickly turn to “PING” (cracks) if you buy on appearance only. Disc Brakes Australia’s Chief R&D Engineer, Steve Gavin, explains:

I have many years of hands-on experience at the track whether it be super sprints, GT Performance, rally or 24hr racing. Part of my role is to push the limitations of the disc brake system and analyse the failures to design a better disc rotor. Possibly one of the biggest challenges was developing a disc rotor that would survive 24 hours of continuous racing on the unforgiving Bathurst circuit. A critical disc change, pit stop was avoided to enable a championship win for the GT Performance class Subaru WRX STi. This product soon became the DBA 4000 series and expanded rapidly throughout the range.

The two most important factors when it comes to disc brake rotors used in extreme applications is heat capacity and thermal stress management.

Heat capacity design is a compromise between having enough metal mass in the friction ring to accept and process the kinetic energy transferred into the brake system to decelerate the vehicle while trying to minimise the rotating mass of the wheel assembly (unsprung weight).

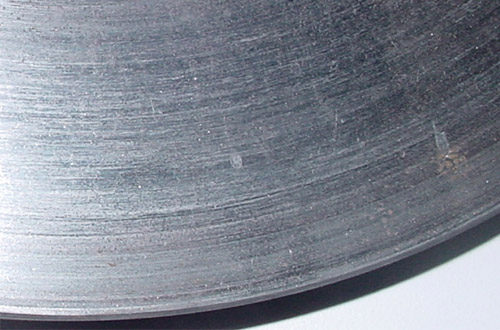

Thermal stress management is all about minimising fatigue to prolong the life of the disc rotor. Regardless of the manufacturer or disc design, grey cast iron will fatigue in motor-sport applications. The thermal expansion from heating and contraction when cooling initiates a stress and strain cycle which is essentially metal fatigue. It is common practice for professional race teams to discard the disc rotors after a known period whether it be the number of laps or hours in race conditions to avoid any unpredicted failures due to metal fatigue.

Plain, Drilled or Slotted disc rotors? Without question, it’s slotted rotors wherever possible.

There are drivers that like to maintain the factory setup with plain discs and this is OK, certainly the disc rotor Fig 2. image was a plain type due to the racing class it was entered.

The purpose of slots in the disc rotor is to evacuate the waste material (dust) from the friction surfaces. The slots will ensure consistent friction performance throughout the life of the disc and pad whereas more scrutiny is required in friction material selection with plain discs to avoid surface glazing and declining friction performance.

This leaves us with drilled or drilled and slotted discs. Drilled disc rotors are not recommended for track use of any kind. Unfortunately, the drilled holes are focus points where stress and fatigue will accelerate and eventually result in crack formation. Drilled disc rotors have proven to improve braking performance on the street where normal driving conditions rarely exceed 250C and stress is not a concern.

Heat treatment, Cryogenics, Vibrational stress relieving? Yes, there are several treatments or processes applied to disc rotors marketed in the industry. Typical processes such as Cryogenic treatment is a method where the discs are treated post manufacturing. The discs are often sourced direct from an external or unknown manufacturer and processed later by the distributor who may not have detailed knowledge of the material properties. The risk of not receiving the desired performance is real.

DBA 4000 series one piece and DBA 5000 series two-piece disc rotors undergo a thermal stress cycling procedure during the manufacturing process to ensure the metal structure is at its optimum to ensure maximum performance out of the box.

Friction Materials (Brake Pads)? There are hundreds of different friction materials available for racing applications. Choosing the best material is a personal one as driving styles differ with confidence and experience. It’s important to cover some basics when it comes to making the best choice. Many O.E or factory supplied friction materials are designed for comfort and moderate performance in normal street applications. Often these are NAO (Non-Asbestos Organic) class pads that are gentle on the rotors and make little noise. These pads are not intended for prolonged high temperature applications.

Sintered metal, carbon metallic, semi metallic pads as the name suggests have varying amounts of metal as part of the compound. These pad materials offer a high friction coefficient and higher temperature resistance. Each pad has different performance characteristics so it pays to do your research.

Key friction material metrics to focus on are;

Initial bite – The friction coefficient upon the first application

Peak effectiveness – The point where the material reaches its highest performance. Usually related to temperature

Release speed – Responsiveness when you release the pedal

Modulation – Is a technique of applying and releasing the brake pedal to effectively decelerate while maintaining maximum control and applying the least amount of stress in the brake system.

Wear – Obviously wear and tear is critical for product life and cost effectiveness.

Friction material suggestion to consider;

Super Sprints – High initial bite with a peak effectiveness at lower temperatures (100C to 150C). This may support a late braking driving style for short sprints.

Sprint circuit racing approx 10 to 15 laps – Moderate initial bite increasing to a peak effectiveness at 300C to 400C. This may provide the most effective brake and tyre friction as the same time, typically lap number 3 or 4 for strategic, competitive driving.

Endurance circuit racing – Moderate initial bite with a very flat peak effectiveness curve from 300C to 500C. Typically slightly lower coefficient of friction than the above race pads to ensure longer pad and rotor life.

Please note;

The information shared in this text is a general guide only. Each person’s driving style differs from one another and it is the responsibility of the driver to determine which braking products are best suited to their own driving behaviour. The above information is a guide only to assist the driver in conducting their own research

Disc Brakes Australia does not take responsibility for performance outcomes, as a result of sharing this knowledge.