Failure Mode

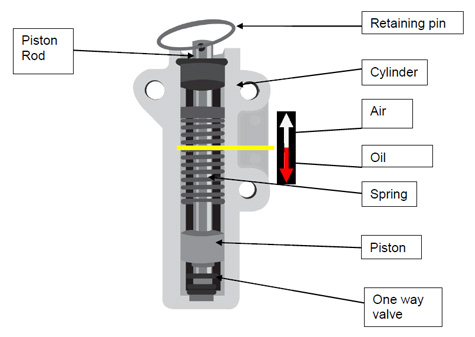

It is critical that the hydraulic tension is checked before installation. There is a small chamber in the hydraulic actuator/tensioner that air can leak into which can lead to a "non-damping" situation. The manufacturers of the hydraulic actuators refer to this as "Sponge State".

If the tensioner/actuator is affected by the "sponge state" then a bleed out procedure is required and failure to do so can lead to the timing belt jumping teeth causing expensive engine damage.

The retaining pin should only be removed after the installation of all components. The reason for this guideline is that once installed, the hydraulic tensioner is in a vertical position and there is no risk of air expel. Also, if the pin is released with no resistance and travels to its fully extended position air will expel and the sponge state will have occurred.

Other components within the timing drive can affect the performance of the actuator/tensioner so it is critical that the vehicle manufacturer’s installation procedures are followed accurately.

It is also recommended that hydraulic actuators/tensioners should be stored in a vertical position with the visible part of the piston rod pointing to the top to avoid air expel.

Checking the Unit for Sponge State

The pin retaining the piston rod should not be removed until it is installed as recommended by the vehicle manufacturer instructions. If there is any movement in the piston rod after correctly following the installation procedures, remove the hydraulic tensioner leaving the piston rod in the extended position for further inspection.

The piston should be solid and require considerable force to move, this can be checked by pressing the piston against a firm object. If there is any movement, the unit will require a bleed out procedure. If the bleed out procedure is not followed, premature failure will most likely occur.

Bleed Out Procedure

WARNING

1. Set the actuator/tensioner with the piston rod in the extended position to a vertical press, and then slowly compress the piston rod to the bottom end, then slowly extend. Repeat this step 2 to 3 times (each cycle should take no less than a minute to avoid damage).

2. Compress the rod slowly, and then align the set hole of the rod with the set hole of the auto tensioner body and insert the retaining pin.

3. Install the auto tensioner in position. Leave the wire or pin installed.

4. Follow the vehicle manufacturer's specific installation procedures to ensure problem free operation.

5. If there is still movement in the piston rod, repeat this procedure.

NOTE: If after repeating this procedure several times and the piston rod does not return to a solid state replace the tensioner.

As the "sponge state" is avoidable by following the vehicles manufacturer's installation instructions and/or being aware of the above checks and corrections, no warranty claims shall be honoured by Gates when sponge state has occurred.

This article was shared with the Mechanic.com.au Community by our Premier Community Partner Gates Australia

To provide feedback, seek further information or ask any questions, don't hesitate to contact Gates Australia