Most of us replace brake pads on customers’ vehicles almost every day, and most of us can do so in well under thirty minutes. However, are we always sure we are fitting the right brake pads to suit a particular customer’s particular needs and requirements? For example, two customers might own identical 4WD vehicles; one is bog standard and belongs to an accountant that never ventures off-road, while the other carries 500 kg of accessories and tools and belongs to a mobile mechanic that fixes farm tractors in remote areas. Should we then fit the same brake pads to both vehicles?

Common sense tells us no, we should not fit the same brake pads because our hypothetical customers have different braking requirements and driving styles, but how do we know which brake pads are best suited to each hypothetical customer's needs? This is not always an easy question to answer, but in this article, we will answer this and other questions by taking a closer look at Bendix brake pads in terms of the specific brake friction material formulations Bendix has developed to address the specific braking requirements of different vehicle categories under different operating conditions.

Before we get to specifics, though, we need to answer the question below to provide some context to the focus of this article, which is about our responsibility to select the right brake pads to suit particular applications, as opposed to how brake pads are made-

There was a time when conventional wisdom held that making brake pads was more art than science, which was easy to believe since most brands of brake pads seemed to work equally well in all applications. Moreover, the oldest among us will remember a time when a) any given brand of brake pads was as likely to be noisy as almost any other brand of brake pads, and b) almost all brake pads gave off a sticky layer of black dust and resin residues that was difficult to remove from alloy rims.

In the interest of brake pad manufacturers, it must be stated that the brake systems of thirty and forty years ago were rather crude, and in many cases, what passed for brakes was merely present because the law required that vehicles be equipped with brakes. Of course, things are different today because modern brake systems are integral components of the overall design(s) of new vehicles, not merely tacked-on accessories that did not work nearly as well as they perhaps could have done.

So, when we consider the multiple roles modern brake systems play in improved vehicle occupant safety, we must also accept the fact that the process of making high-quality brake pads has evolved from dark magic and guesswork to being an exact science. For instance, while brake pad manufacturers like Bendix still use various combinations of around 400 available and legal ingredients to formulate friction materials, they no longer use those ingredients to (kind of) reverse engineer friction materials that copy the performance characteristics of OEM brake pads.

In fact, Bendix spends enormous amounts of time, energy, and money to formulate and develop bespoke friction materials for brake pads for specific purposes and applications, as opposed to brake pad friction materials that cover the largest possible number of applications that share similar or nearly similar features and characteristics.

We can best put this approach into some context by using tyres as an analogy. Consider All-Terrain off-road tyres- although these tyres perform reasonably well in sand and mud, as well as on paved surfaces, they do none of these things very well. By way of contrast, consider the recommended tyres on a new Ferrari; these tyres are designed specifically to provide large amounts of traction at high speeds, as well as have superior structural strength to withstand high cornering and braking forces without deforming or losing traction. In other words, the tyres on an exotic sports car perform exceptionally well because they were designed and constructed for use in a specific application.

Modern Bendix brake pads work in much the same way, in the sense that a specific friction material formulation will work exceptionally well in the application it was designed for, and while it may work in other applications, it will not work nearly as well, which brings us to-

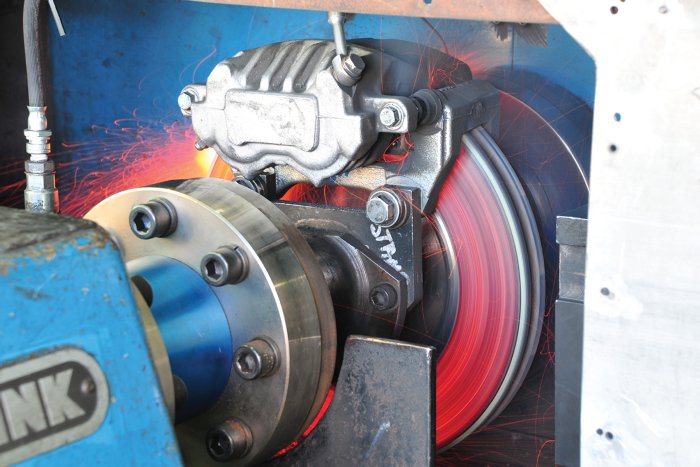

None of us would knowingly or worse, intentionally fit the wrong brake pads to a customer’s vehicle, but the problem we have is that we just don’t know how any given customer will use their vehicle two weeks after we have fitted new brake pads. So, given that a major consequence of fitting the wrong brake pads is severely overheated brake pads and rotors, albeit not always to the extent shown in the image above, we need to be sure that the brake pads we fit will perform as expected.

Fortunately, Bendix has an excellent online resource that includes technical and product support via a call centre, which breaks down their product range by vehicle categories. However, since many vehicle categories can have one or more possible predominant uses, it is often up to us to divine how some customers use their vehicles most of the time. This is a particularly important point because while some brake material formulations may work in multiple applications, some friction material formulations may not meet the demands of some ADAS systems like, for instance, Automatic Emergency Braking, Stability Control, or Electronic Brake Distribution in some applications.

So, assuming that we are going to fit Bendix brake pads to a customer's vehicle, how can we be sure which Bendix brake pads are best suited to that customer’s particular needs and requirements? Well, we can never be 100 per cent sure, because we can never know how that customer will use their vehicle some of the time, but we can do the next best thing, which is to be sure how they use their vehicle most of the time. Here is how to do this-

Use visual cues

One of the most useful visual cues is the presence or lack of accessories on 4WD vehicles like bull bars, drawbars, side step plates, additional fuel tanks, built-on toolboxes or water tanks, modified suspensions, and the like. Accessories like this are often accompanied by chipped paintwork along the bottom of the vehicle, accumulated dust and mud in the wheel wells, or sometimes, lots of dust and grime in the engine compartment.

Conversely, the lack of accessories and a clean chassis usually means that the vehicle never (or very seldom) ventures off-road, and therefore, it spends its life on urban roads as a daily driver or people mover.

If we cannot speak to the vehicle’s owner directly, observations like the above can give us a good idea of how customers use their vehicles most of the time, which makes it a lot easier to make an appropriate choice regarding which brake pads will be best suited to the customer’s needs and requirements.

The same principle(s) apply to passenger vehicles. The presence of things like highperformance tyres, a modified exhaust system, a larger engine than the standard engine, and expensive alloy rims usually means that the vehicle‘s owner would almost certainly prefer braking performance that exceeds OEM levels.

Conversely, the lack of any performance parts on a passenger vehicle usually indicates that the vehicle is an urban-based daily driver, and OEM-equivalent braking performance will usually suffice.

Ask some pertinent questions

If we can speak to vehicle owners directly, the few minutes it takes to glean some extremely important information from them is always time well spent. Nobody knows how customers use their vehicles better than customers do, so we might ask questions like the ones below-

There are, of course, more questions one could ask, but the point is that the questions we ask should give us answers that paint a complete picture of the vehicle’s predominant use, which must always be the guiding principle that underpins our selections of Bendix brake friction materials. Having said that, let us look at some-

Bendix is not only the largest manufacturer of brake pads in Australia, and, therefore, their product range covers close to 100 per cent of the national car parc as well as most of the car parc in New Zealand, which means that Bendix offers an effective braking solution for every braking problem. Moreover, Bendix makes brake pads to suit Australian conditions taking into account our-

- and advances in materials, technology, and the increasing computing ability of automotive control modules. So, let us start by looking at some of the features of the Bendix brake pad product ranges we can choose from, but note that the Bendix product range is too big to cover extensively in this article, but more details are available here-

General CT brake pads

Engineered for everyday driving applications, General CT brake pads deliver smooth, quiet, and consistently predictable braking right out of the box, which includes Bendix noise-absorbing shims. General CT brake pads also feature Bendix’s STEALTH Advanced Technology and new Blue Titanium Stripe that eliminates the need to bed in the new pads.

4WD/SUV brake pads

Bendix offers low noise and low dust brake pads for all popular 4WD and SUV applications. These brake pads are made with 4WD-specific materials that include Enhanced Phenolic Resins to maintain the pads' ability to cope with high brake temperatures over extended periods in all off-road and city driving conditions.

4WD and SUV brake pads also feature the new Blue Titanium Stripe that eliminates the need to bed in the new pads.

Ultimate brake pads

Bendix Ultimate brake pads are expressly designed to provide superior braking performance in sports, prestige, and high-performance vehicles. Apart from providing high wear resistance and brake fade at high speeds and temperatures, Ultimate Brake pads also offer excellent stopping power when the brakes are cold.

Bendix Ultimate brake pads also feature purpose-designed noise-absorbing shims to reduce vibration and brake noise.

Ultimate 4WD Disc Brake Pads

Designed to provide consistently reliable and predictable braking performance in 4WD vehicles that operate in extreme conditions or regularly tow caravans, boats, and trailers, Bendix Ultimate 4WD Disc Brake Pads are now available for purchase separately, whereas these pads were previously only available as part of the Bendix Ultimate 4WD Brake Upgrade Kit.

Note, though, that Ultimate 4WD Disc Brake Pads are recommended for use with slotted brake rotors to improve the evacuation of brake dust and gas from the brake pad/rotor interface at high brake temperatures.

EV-Hybrid brake pads

Made from organic materials and containing less than 0.5 per cent of copper by weight, Bendix EV-Hybrid brake pads provide both low noise operation and low dust formation to minimize the impact these pads have on the environment.

Euro+ brake pads

Bendix+ brake pads are formulated to meet the brake dust emissions regulations in the European Union, where brake dust is now considered to be a major environmental pollutant and human health hazard.

Having said the above, Bendix Euro+ brake pads meet the strict requirements of ECE Regulation 90, which among other things, demand that brake pads for European vehicles be tested for the following-

Based on the above, Bendix Euro+ brake pads meet all the criteria that are required for fitment in all European-made vehicles, as well as in vehicles made in countries that have adopted ECE Regulation 90, even though these countries may not be part of the European Union.

The Bendix brake pad ranges we have outlined above cover most of the applications we see in our bays every day, but brake pad ranges we have not covered include-

- about which more information is available here, which brings us to the topic of-

There is an old proverb that says one cannot make a silk purse from a pig’s ear, which in the context of modern automotive brake systems, means that we cannot expect Bendix brake pads to work as expected when we fit them to damaged, worn, or previously overheated brake rotors.

Therefore, Bendix recommends that brake rotors be machined as a part of all brake pad replacements, but the problem with machining brake rotors is that the process never results in the optimal surface finishes that are required to bed in new brake pads efficiently. One common remedy for this is to smooth out the rough turned finish with a suitable abrasive material while the rotor is still on the brake lathe, but this usually results in a directional groove pattern that can cause new brake pads to overheat severely upon first use of the brakes.

So, while conventional methods of resurfacing brake rotors have a legitimate place even in today’s high-precision car repair industry, we would suggest that having brake rotors ground in the same way that flywheels are ground results in rotor surface finishes that match those of new out-of-the-box brake rotors very closely. Thus, this provides Bendix brake pads with optimal conditions to work as both designed and expected right from the first brake application after installation, but at a significantly lower cost than replacing the rotors, which brings us to-

Although Bendix makes some of the best brake pads that are commercially available in Australia and the rest of the world today, it is worth remembering that there are no such things as perfect brake pads.

In the real world, no brake pad can offer the best of all possible worlds under all operating conditions. This means that when we select Bendix brake pads for a particular application, we have to weigh several factors against each other to arrive at the best possible solution for our customers’ brake problems, as opposed to arriving at the perfect solution for our customers’ brake problems.

In practice, this means that we have to manage our customer's expectations, while at the same time, conducting a cost-benefit analysis that takes into account factors like(among others)-

As a practical matter, every aspect of brake pads and their operation involves trading off something against something else. For instance, one can have excellent stopping power and no dust, but that comes at a price penalty. Similarly, one can have a low replacement cost, but depending on the application, a low replacement cost could come at the expense of stopping power and durability.

Bendix offers car owners brake pad solutions that address most consumer demands in terms of low brake dust emissions, low to no brake noise, high durability, excellent brake performance, and a positive pedal feel. Nonetheless, it is up to us to educate our customers on the fact that no single brake pad can offer perfect solutions to all possible braking needs and requirements, which leaves us with this-

Although there are no perfect brake pads, Bendix supplies the best possible brake pads for Australian vehicles operating in Australian conditions, and they have done so for several decades. Moreover, given that Bendix also continually adapts and augments their product range with brake products that meet the requirements of new vehicles and technologies, we can always be sure that Bendix can supply the best possible brake pads to meet our customers’

expectations, needs, and requirements, regardless of what vehicles they are driving. And that, we can all agree, can never be a bad thing.