While all major car manufacturers have made great strides in reducing diesel exhaust emissions, and particularly NOx (oxides of nitrogen) in recent years, one manufacturer, Mercedes, has taken the lead in this field with BlueTec, its version of NOx reduction technology that was first introduced in 2006. In this article, we will take a closer look at the package of emission control technologies that constitute BlueTec emission control on Mercedes diesel vehicles, how the system works as a whole, what can go wrong with it, as well as how to diagnose at least some issues that can prevent BlueTec technology from working, starting with this question-

The basis of BlueTec technology is SCR (Selective Catalytic Reduction), and while SCR is not unique to Mercedes, the technologies that supplement SCR, and Mercedes’ proprietary monitoring/control systems make BlueTec arguably the most efficient and effective NOx reduction system in use today. Let us look at the principal components of BlueTec systems-

High-pressure common rail fuel injection

The heart of the system is the fuel injection system that injects fuel directly into the cylinders at a pressure of around 1500 bar through injectors that use Piezo-electric crystals as valves. This makes it possible to split injection events up into five and even seven separate injections to optimise each stage of the combustion process.

Variable geometry turbocharger

Variable geometry turbochargers contain moveable vanes in the turbine side of the housing that control drive pressure in order to control boost pressure more effectively. In practice, a variable geometry turbocharger matches the boost pressure to an engine’s exact boost pressure requirements throughout the engine’s operating range by maximising exhaust flow through the turbocharger at all engine speeds. The practical effect of this is greatly improved boost pressure control, which in turn, improves the engine’s power delivery characteristics while using less fuel.

AdBlue

AdBlue is also known as DEF (Diesel Exhaust Fluid), and while all CSR NOx reduction systems depend on the injection of this mixture of de-ionised water and urea into the exhaust stream, the use of AdBlue in conjunction with sophisticated fuel injection strategies and precise boost control produces NOx reductions of up to 50% on most Mercedes applications.

This short description of BlueTec technologies encapsulates the basic approach to NOx control on Mercedes applications, and while the system generally works very well when it is fully functional, it is as well to take note that the BlueTec system is more complicated than similar approaches to NOx control taken by most other manufacturers, which brings us to-

As a practical matter, BlueTec is a compromise between two other NOx reduction technologies, in the sense that it accomplishes the goals of both, but via a different route. The first involves reducing the amount of NOx that can form in the engine by means such as EGR that affects both power and fuel consumption. The second involves the use of catalytic converters that trap NOx for a period of time before it is burned off by injecting raw fuel into the converter, which obviously affects fuel consumption in the worst possible way.

BlueTec on the other hand, injects precisely metered amounts of AdBlue (Diesel Exhaust Fluid) into the exhaust stream just upstream of the catalytic converter, where the ammonia (derived from urea) in the fluid initiates a process of chemical reactions that ultimately converts NOx into water and nitrogen. This process is known as SCR (Selective Catalytic Reduction), and while it is very effective and does not affect fuel consumption, the system is extremely complex and therefore, sometimes very difficult and time consuming to diagnose and/or repair. In fact, most independent repair shops are somewhat limited in what they can do in terms of diagnosing and repairing BlueTec issues, but despite that, there are some things that most independent establishments can do in terms of BlueTec diagnostics and repairs, which brings us to-

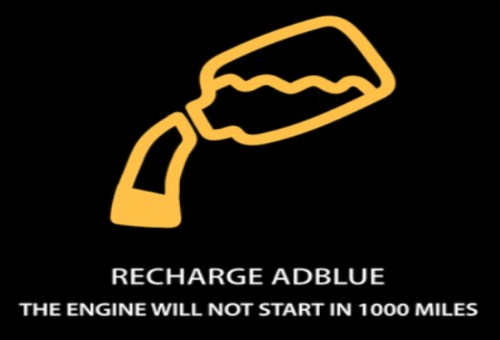

The image above is worth at least a thousand words, but apart from running out of DEF, there are many other issues that will cause a BlueTec-equipped vehicle to enter either a limited start, or a no-start mode. This is an important point to keep in mind because the law in many jurisdictions compel manufacturers to program vehicles with SCR NOx reduction systems so that the engine is disabled under certain circumstances. This is not to protect expensive components in the exhaust after treatment system; this is purely to prevent excessive amounts of NOx from being released into the atmosphere when the SCR system cannot, or does not work as intended.

Nonetheless, let us look at some at some common BlueTec issues, and what you can do to diagnose and correct some issues, starting with-

DEF depletion

DEF is stored in a dedicated tank, and during normal operation of a BlueTec-equipped vehicle, the volume of a full tank of DEF is calculated to last the distance between scheduled services. However, sustained aggressive driving (amongst other factors) can deplete the supply of DEF at a higher rate.

Therefore, all BlueTec-equipped vehicles display a visual warning to the driver, which warning clearly indicates not only the level of the DEF tank, but also based on recent fuel consumption values, how many more times the vehicle can be started with the remaining DEF in the tank. Note though that if the DEF tank is run dry, the engine will enter a no-start mode immediately, and this mode will persist until the DEF tank is refilled and a prescribed tank adaptation procedure is carried out.

Below is a brief description of the adaptation procedure, but bear in mind that at a minimum, you need a scan tool with Mercedes-specific software that can monitor and display Mercedes-specific live data, as well as perform BlueTec adaptations and resets.

As a first step, you need to extract all active and pending fault codes, but take note that the codes you find must NOT be cleared. If you do clear any codes, the system will enter what is known as “Tamper Mode”, and it will automatically enter a limited start cycle even if all repairs are carried out successfully.

When you refill the DEF tank, bear in mind that the fluid level is measured by three level sensors, as opposed to a moving float and rheostat as in a regular fuel tank. For the adaptation to be successful, the scan tool must show all three level sensors as “WET”, which indicates that all the sensors are working as designed. If however, you are sure that the DEF tank is full but the scan tool does not show three “WET” sensors, you have to disconnect the SCR control module to measure the resistance across the terminals of all three level sensors. The typical resistance value of DEF level sensors falls in the 3.8 to 4.2 kilo Ohms range- replace sensors as required if any measured resistance value falls outside of this range.

If you now have three “WET” sensors, the adaptation should be successful, but if not, you need to do a reset of the DEF metering valve. To do this, you need to access the CDI (Common Rail Diesel Injection) control module and follow the prompts on the scan tool screen. If this does not work to reset the engine start counter, you need to reset both of the NOx sensors, the SCR catalyst, and the AdBlue (DEF) Quality monitor. In most cases of DEF depletion, these resets/adaptations will reset the engine start counter, but there is one exception to this rule, this rule involving-

Contaminated / expired DEF

All high-quality DEF that conforms to the ISO 22241 standard consists of a mixture of 62.5% deionised water and 32.5% high-grade urea, which is the source of the ammonia that converts NOx into water and nitrogen. Every important aspect of SCR systems, such as the injection rate and storage capacity is designed around these percentages; in this proportion, the water and liquid urea freeze and thaw at exactly the same rate, which prevents one component in the mixture separating out of the mix in freezing temperatures.

While freezing temperatures are not an issue in Australia, the facts are that all DEF mixtures sold in the world have the same relative concentrations of water and urea on the one hand, and that all DEF mixtures have a maximum shelf life of only 12 months. Moreover, since the DEF tank on some Mercedes applications is under the bonnet, the DEF on these applications is particularly susceptible to contamination with water, windscreen washer solution, and even antifreeze. Even trace amounts of any contaminant can trigger a no-start condition, so pay particular attention to the quality of the DEF when you deal with BlueTec issues.

The most reliable way to test DEF for contamination is to use a refractometer that is designed specifically to test DEF. This test is based on the way light is refracted (bent, or deflected) when it passes though a liquid; therefore, if the relative concentrations of water and urea change for whatever reason, the way light passes through the mixture will also change. Of course, the quality of the test result depends entirely on both the quality and calibration of the test equipment, but assuming both are acceptable, good quality, pure DEF will show a urea content of between 32% and 33%, which is perfectly acceptable.

However, readings outside of this range indicates a measure of contamination of the DEF, which requires that the entire DEF injection system be removed, drained, flushed, and purged strictly in accordance with Mercedes’ prescribed procedures. Bear in mind though that since storage conditions can directly affect the quality of DEF mixtures, it is always wise to test the urea content of all DEF products, even if the product is still well within its allowable shelf life. Failing to do this could result in a customer’s vehicle being immobilised, which if you caused the issue, could cost you several days of labour and many thousands of dollars. The good news is however, that a high quality refractometer is not expensive and that by investing in one, you can protect yourself against potentially expensive comebacks.

DEF injection system issues

Many, if not most SCR catalyst efficiency codes are the direct result of issues in the DEF injection system. Blockages and leaks anywhere in the system (particularly leaking metering valves/injection nozzles) cause too much or too little DEF being injected and both conditions can cause catalyst efficiency codes.

In practice, the DEF is extracted from the tank by a pump, which pumps the DEF through a series of heaters and a metering valve before it is injected into the exhaust stream through an injection nozzle. If you have a suitable scan tool, you can run a leak test: the ECU will keep the injection pump running (and the system pressure at about 5 bar), which allows you to perform a visual inspection of the injection system lines and components. Leak sites will show a whitish residue, but bear in mind that you may have to remove the injection nozzle to verify that it is, or is not leaking under a constant pressure.

Faulty NOx sensors

SCR systems (BlueTec, included) use upstream and downstream NOx sensors to monitor the efficiency of the catalytic converter, and as with oxygen sensors, the ECU/SCR control module compares the output of both sensors to calculate an efficiency value for the converter.

However, since NOx sensors are very expensive, all other possible causes of implausible, incorrect, or erratic NOx values must be investigated before any NOx sensor is condemned out of hand. The figures listed below illustrate good and implausible NOx readings, but take note that these examples are intended purely to be illustrative, and should therefore not be used as the basis for any diagnostic procedure on a BlueTec system

Good catalyst performance

281 parts per million NOx upstream

64 parts per million NOx downstream

These values represent a 77.2% reduction on NOx across the SCR catalytic converter, which indicates an excellent efficiency value. While a 77+% reduction is an exaggeration, it serves to illustrate the point that stable NOx readings in closed loop operation should show a large difference between upstream and downstream values, with values falling in the 30% to about 50% being more representative of a fully functional BlueTec system.

Implausible reading

1335 parts per million NOx upstream

77 parts per million NOx downstream

This is clearly an implausible reading that likely indicates either a defective NOX sensor, or a replacement NOx sensor that is incompatible with the other NOx sensor on the affected SCR catalytic converter.

Inaccurate / implausible reading

221 parts per million NOx upstream

342 parts per million NOx downstream

The downstream value can never be higher than the upstream value; even if the SCR catalyst had failed completely, the up -, and downstream NOx readings should be the same, or be very close to the same.

Metering valve issues

Once you are certain that the DEF storage and injection systems are functional, you can use a suitable scan toll to perform a test of the metering valve. This test involves activating the injection pump remotely with the metering valve removed from the exhaust system. The valve should emit a very finely atomised spray pattern consisting of three clearly defined cones, and the mass of the DEF emitted during the test should come to about 15 grams. Suitable electronic scales can be had for a few dollars, but while you have a sample of DEF, be sure to check its quality with the refractometer we mentioned earlier.

SCN (Software Calibration Number) coding

It has been this writer’s experience that the few basic checks and tests outlined above will usually resolve most common issues on BlueTec systems. However, if performing the checks above does not resolve the issue, it usually becomes necessary to evaluate the overall functioning of the NOx control system while the vehicle is being driven normally with the emission control system in closed loop operation.

This assumes that the vehicle is not locked into a no-start mode, in which case it may be necessary to reflash or update the SCN coding to reset crucial control modules such as the fuel control unit and/or others, including the SAM (Signal Acquisition) computer. This module is also known as the Signal Actuation Module, and its function is to transmit and receive data to and from sensors (including sensors, switches, and controllers in the emission control system), as well as to control and/or monitor various systems, which includes transmission control.

However, the problem with SCN coding is that it can only be done via servers that only Mercedes dealerships have access to, which precludes independent workshops from performing this function. While it is sometimes possible to obtain SCN coding certification, the process is long and tedious, so it is sometimes easier to refer a vehicle to the nearest Mercedes dealership for specialised diagnosis and repair.

While BlueTec systems are often very tricky to diagnose and repair, this fact should not deter any workshop owner, manager, or mechanic from learning as much about the system as possible. In fact, the several issues that a properly equipped independent workshop can successfully diagnose and repair can be extremely profitable, provided that technicians recognise the limits of what they can, cannot, and absolutely should not attempt in terms of diagnostics and repairs of BlueTec systems. Nonetheless, much of BlueTec technology is relatively plain sailing, so don’t turn good business away unnecessarily.