In Part 1 of this two-part article, we discussed the friction coefficient of brake pads, which is a) a function of the formulation of the friction material, and b) the basis from which engineers calculate brake system calibrations to suit a particular vehicle design. Thus, it could be argued that in some ways, modern vehicles are built around their brake systems in general and around their brake pads, in particular.

In Part 2 of this article, we will discuss some specific negative effects that brake pads with a low coefficient of friction have on the operation and effectiveness of some ADAS systems. In addition, we will also explain how to decode some of the numbers printed on some brake pads, as well as look at some specific attributes of brake pads that could mean the difference between some ADAS systems working as expected- or not. Let us start by looking at-

Although stability control systems work in much the same way across all applications, there are vast differences between how different vehicles react to brake inputs applied to individual wheels during an abnormal condition such as a rear-end slide caused by aggressive cornering. This is aggravated by whether the driving wheels are on the rear or front axle, but as a matter of scientific principle, the heavier the vehicle is, the more lateral (sideways) acceleration the vehicle will exhibit during a rear-end slide compared to a lighter vehicle travelling (or sliding)at a similar speed.

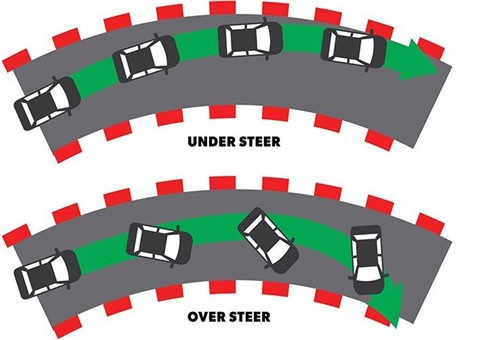

The above being the case, we need to add one more thing to the proverbial mix- the degree of over or under steer the vehicle exhibits during normal driving conditions because few vehicles have precise or neutral steering characteristics. Of course, over or under-steering has much more to do with how a vehicle is designed and constructed than it has to do with the efficiency of its brake system but the point is this: both under and oversteer can be made much worse by a stability control system that is not calibrated to work with the friction coefficient of unsuitable brake pads. Consider the image below-

Image source: https://www.gorv.com.au/wp-content/uploads/2019/03/caravan-rollover-2.jpg

The two examples of abnormal steering are largely self-explanatory, albeit somewhat exaggerated for clarity, but here is how the stability control system will correct these situations, assuming of course, that the vehicle is fitted with the correct or recommended brake pads.

In the case of understeer, the ABS control module will detect that the lateral acceleration at the vehicle’s rear end does not match the steering angle set by the steering angle sensor. As a result, the ABS control module will apply precisely calculated braking forces to the inside wheels to force the vehicle into following the steering angle set by the front wheels. Put differently, the braking forces on the inside wheels will “pull” the vehicle into the corner.

In the case of oversteer, the ABS control module will detect that the lateral (sideways) acceleration of the vehicle's rear end exceeds the steering angle set by the steering angle sensor. As a result, the ABS control module will apply precisely calculated braking forces to the outside side wheels to force the vehicle into following the steering angle set by the front wheels.

Put differently, the braking forces on the outside wheels will act as anchors, which will have the effect of reducing the lateral acceleration at the vehicle's rear end. Of course, in cases of severe oversteer, there is likely to be a measure of counter steer present but if the ABS control module gets its calculations right, the braking forces on the outside wheels will force the vehicle to pivot sufficiently around its mid-point to correct the rear-end slide without inducing a slide in the opposite direction.

The explanations given above are admittedly grossly oversimplified but it is worth keeping in mind that the ABS control module performs highly complex and potentially life-saving calculations several times per second, and all of them are based on the assumption that the vehicle is fitted with the correct brake pads.

Here is why this is crucially important: all brake pads need to be at their optimal temperature to work as both designed and expected. Unfortunately, no brake pads can reach that temperature instantly, so the best brake pads for any given application are pads that can reach their optimal working temperature in the shortest possible time. Thus, in all cases, between the moment the brakes are first applied and the moment the brakes have heated up sufficiently to work as expected, there is a period during which the efficiency of the brake pads is very low compared to their maximum efficiency.

Depending on the vehicle’s speed and the brake pressure that is applied, this period is typically less than two seconds for OEM or OEM-equivalent brake pads, but note that this is not the same as saying that the brakes do not work for two seconds after a brake application. In practice, if the ABS applies the brakes 8 to 12 times per second, the efficiency of the brakes l begins to increase progressively after the first brake application since the brake pads begin to heat up during the first brake application, which brings us to-

Observant readers will have noticed that we mention OEM and OEM-equivalent brake pads often, and as a general rule, these brake pads do a decent job during both normal driving and ADAS-initiated corrective action(s). However, modern brake systems do have a potential complication, this being something called brake fade compensation.

As a practical matter, this system can infer the temperature of the brakes based on, among other things, the average brake usage, the vehicle's speed, and the number and intensity of recent brake applications. The purpose of this system is to prevent potentially dangerous brake fade caused by overheated brakes, so if the system detects abnormally high brake temperatures, it may temporarily disable systems like stability control, traction control, and adaptive cruise control to allow the brakes to cool down to a safe level.

To ensure proper operation of the brake fade compensation system, it is programmed to assume that the vehicle is fitted with OEM or OEM-equivalent brake pads that produce a predictable amount of braking performance at any given brake pressure and temperature. So, on vehicles with the correct brake pads, and provided the tyres have not lost traction with the road surface, the stability control system can typically correct over and understeer conditions long before the brakes get hot enough for the ABS control module to activate the brake fade compensation system.

So the complication is this: if our hypothetical vehicle is fitted with brake ads whose friction coefficient is too high or too low, the brake pads will almost certainly not produce a predictable amount of braking performance at any given brake pressure and temperature. If the friction coefficient is too low, the brake system may not be able to apply enough brake pressure to individual wheels to correct a slide because the brake pads are too “slippery”.

If, on the other hand, the friction coefficient is too high, the brake system may apply the correct amount of brake pressure but because the brake pads are too aggressive for the application, the ADAS-initiated braking action might cause an over-correction of say, a dangerous slide. This could have unpredictable consequences, including causing the vehicle to land upside down in a ditch or the vehicle colliding with other vehicles, trees, and lamp posts- among other things.

From the above, it should be clear that it is imperative always to fit brake pads with the recommended or specified friction coefficient to ensure that critical ADAS systems always work as expected. Having said that though, this is not always easy because brake pad manufacturers do not usually publish this type of technical information, but in some cases, brake pad manufacturers do supply this information in the form of numbers or letters printed on their products, so let’s look at-

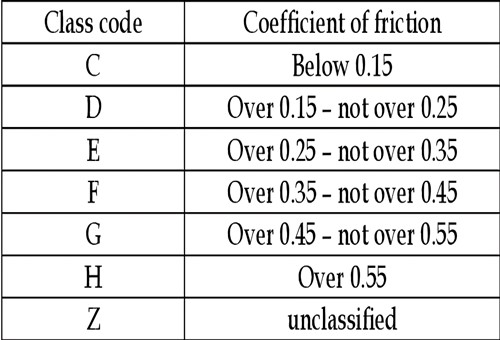

Although there are no standards in force anywhere to oblige brake pad manufacturers to rate the friction coefficients of their products in the same way, there is a way to decode the letters on some brake pads that makes at least some logical sense. To do this, though, it is necessary to understand that the friction coefficient of all brake pads changes as their temperatures change, even though changes in the braking performance of (most) high-quality brake pads (based on brake temperature changes) are not always detectable by average drivers under normal driving conditions. Consider the table below-

Image source: https://www.santa-brakepart.com/news/everything-you-should-know-about-brake-pad-friction-coefficient/

As a general rule, OEM and OEM-equivalent brake pads meant for general use in light passenger vehicles have friction coefficients of about 0.3 to 0.4, while high-performance brake pads meant for track or racing use have friction coefficients of about 0.4 to 0.5. As stated elsewhere, the lower the friction coefficient, the higher the brake pressure required to produce a useful braking effect on the vehicle. It is also worth noting that while the friction coefficient of all brake pads diminishes sharply at very high brake temperatures, the point at which the friction coefficient begins to diminish is different for different brake friction material formulations.

So if we refer to the table above, we see that friction class “F” is roughly representative of OEM brake pads meant for general use in light passenger vehicles. However, this is only half of the story because the indicated friction class (“F” in this case) will always be followed by a second letter, as required by SAE standard J886. Here is how this works-

The first letter ("F" in this case) indicates the low-temperature range (93 degrees C to 204 degrees C) while the second letter indicates the high-temperature range (148 degrees C to 343 degrees C). Thus, if both letters are the same ("FF" in this case) it means that the brake pads have useful coefficients at both low and high temperatures, which would make this particular set of brake pads a viable replacement for OEM pads, provided of course, that the OEM brake pads have similar friction coefficients.

This is a crucially important point because although brake pad manufacturers are obliged to use the two-letter code to identify temperature ranges as set out in SAE standard J886, brake pad manufacturers are not bound by a single system to test and assign friction codes to their products.

So while the friction code system does have some advantages, it also has major pitfalls because there is no objective way to divine the differences between friction class "FF" assigned by one manufacturer and, say, friction class "GG" assigned by another manufacturer in terms of the stability of the high and low friction coefficients of the two sets of brake pads.

Based on this, the best advice this writer can offer is to stick to one brand of brake pads (Bendix comes to mind), because Bendix makes specific recommendations on suitable brake pads for different applications. It is worth noting that such recommendations are based on (test) results obtained in their in-house research and test facilities, which removes much of the guesswork involved in selecting brake pads for specific applications, which brings us to-

While abuse of the brakes usually results in discoloured and damaged brake rotors like the example shown here, fitting the wrong or unsuitable brake pads to a customer's vehicle often produces the same result. Therefore, to avoid such a situation and an expensive comeback, it helps to remember a few things when we replace the brake pads on customers’ vehicles, such as, for instance, that-

Ceramic brake pads are not all the same-

Due to their association with motorsports, it is easy to think that no ceramic pads are suitable for use on daily drivers. The fact is that there are hundreds of ceramic-based friction material formulations available in the aftermarket, and many are designed specifically for use on daily drivers that live primarily in urban areas.

The trick to selecting ceramic pads for a daily driver is to compare the friction profile of the aftermarket pads to that of the OEM pads. Provided the friction coefficient of the aftermarket ceramic pads does not differ from that of the OEM pads by a meaningful amount, the aftermarket ceramic pads will provide smooth, quiet, predictable, and reliable braking performance on most light passenger vehicles.

Organic pads should not be used in heavy-duty applications

The problem with organic brake pads is that they do not produce a lot of heat, meaning that their friction coefficient remains low, although sufficient for normal driving conditions.

Therefore, do not use organic pads in heavy SUVs and pick-up trucks because they do not provide the "stopping power" required to be effective in these applications under normal driving conditions at relatively low speeds.

Semi-metallic brake pads wear out brake rotors faster than other types of brake pad

Although semi-metallic brake pads are typically standard equipment on SUVs, pick-up trucks, and high-performance cars, the high metal content of these pads makes them greatly more abrasive than other types of brake pads.

Thus, if you have customers who complain that “they don’t make brake rotors like they used to”, it is worth looking at whether the vehicle is fitted with semi-metallic pads. Unfortunately, the only viable replacement for semi-metallic pads in these applications is some types of ceramic pads, but we do not recommend this route because it is very easy to make the wrong choice.

The problem is that although most ceramic brake pads offer superior braking performance when they are hot, their friction coefficient is (usually) low when they are cold but worse, their friction coefficient drops precipitously and without warning when they overheat, which could result in catastrophic brake fade during an ADAS-initiated emergency braking event, which leaves us with this-

We hope that this short series of articles has given you some new insights into the close relationship between the friction coefficient of brake pads and the efficiency (or otherwise) of several ADAS systems. While there is much to consider and keep in mind about this relationship, the best way to avoid potential liability issues is never to use brake pads that come in plain white boxes and to think twice about fitting brake pads that may not have been designed for use in our harsh climate in your customers' vehicles.

Therefore, play it safe and always remember that saving a few dollars on brake pads with an unknown or doubtful provenance is a very bad idea. The costs that may result from doing so could have serious and far-reaching financial implications for you and your employer if an ADAS system on a customer's vehicle fails because you inadvertently fitted unsuitable brake pads to that vehicle.