Using their cars these days people are surrounded by ‘systems’. The visible ones such as electronics and connectivity have become common place. However, rarely do people consider the hidden systems. One key system are the brakes. They are often being taken for granted, and few people actually consider how they work and how they safely bring the vehicle to a critical stop when needed. Let alone ask themselves, is there any way I can improve my brakes and create a safer environment for myself and my passengers?

To assist with recommending the ‘right’ brake for your customer, let’s first take a closer look at what they may have as “standard” brakes and their performance aspects.

Most vehicles from the factory are fitted with plain brake rotors. There are some niche vehicles with alternatives, but we will get to those further on. The standard plain face rotor works by creating friction between the rotor and the brake pad face. Depending on the driving type and what extra driving activities are undertaken, these rotors can, if abused, warp or be damaged, prematurely limiting life. That said, under normal general driving conditions a plain rotor is more than sufficient for daily use and will provide for thousands of kilometres of driving. Hence why these are the application of choice as standard rotors in most OE vehicles.

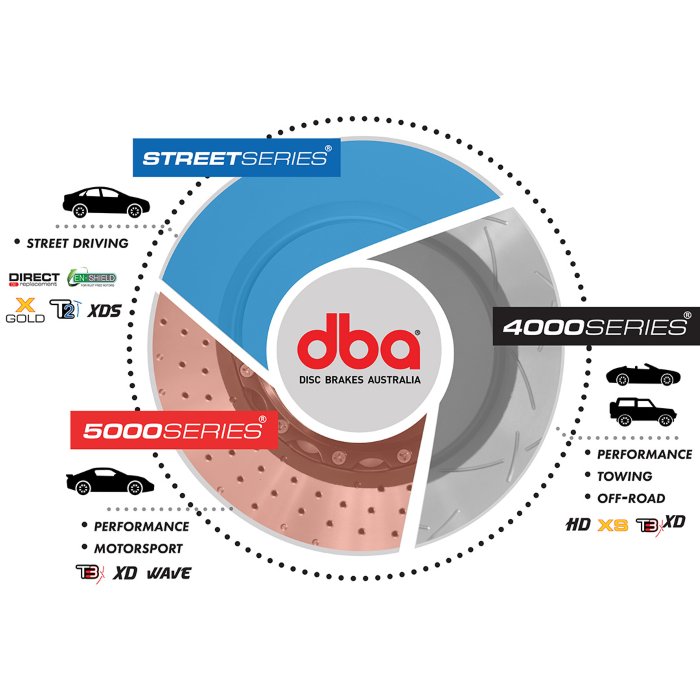

DBA STREET SERIES rotor (OE replacement)

If your customer is looking to not only improve the braking performance but enhance the look of their vehicle, a good place to start are DBA “slotted” rotors. These rotors can be added without any upgrades or without changing any pad profile, unless the customer wishes to. The base rotor for DBA’s slotted designs is essentially the same – unless the customer opts for a high-performance rotor such as the DBA ‘5000 SERIES’ – and the materials and the way they are manufactured are consistent with any OE supplied rotor. So what are the benefits of a slotted design? Slots are designed to allow gases and brake dust to escape from the system. The benefit of this is that it creates better contact between the rotor and the pad. How? The microscopic particles of worn rotor and pad as braking occurs are expelled along the slot paths resulting in reduced heat and enhancing life of the brake system. This may also minimize warping under extreme conditions depending on your driving habits. The other improvement is that the slots aid in “cleaning” the pads as they pass over the slot edges aiding in minimizing pad build up and inhibiting brake shudder. The slots on rotors come in a variety of styles and profiles but essentially do the same function. For most vehicles DBA provides two different slot patterns across its three tiers of disc rotors (STREET SERIES, 4000 SERIES, and 5000 SERIES). These can then be coupled with different styles of brake pad composites to further enhance performance.

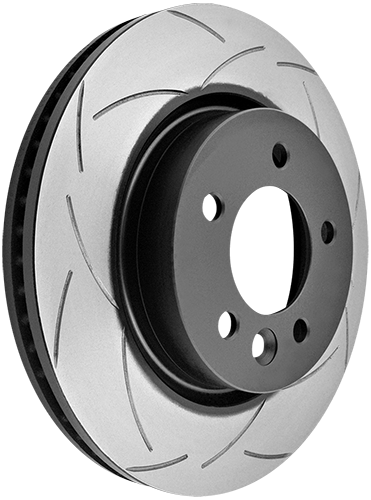

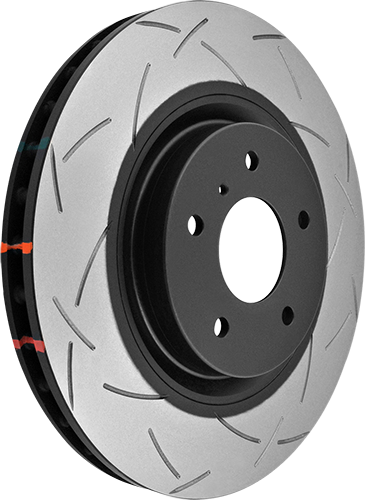

DBA STREET SERIES T2 and 4000 SERIES T3 slotted rotors

For those seeking a further visual differentiator and as replacement for some European marques, DBA supplies either drilled only or drilled and slotted variants. These designs allow gas/particle “venting” as per slotted only versions, but the cross drilled holes further facilitate the outgassing. The cross drilling may also “clear” water in wet conditions, allowing for earlier dry braking. Additionally, in parked postion, the cross drilling provides a great aesthetic for the vehicle. The DBA range as outlined is designed for applications from daily driving (STREET SERIES) to performance (4000 SERIES, 5000 SERIES).

DBA STREET SERIES EXDS and 5000 SERIES XDS T3 rotor

For further information contact Disc Brakes Australia (DBA) on 1800 730 039, email [email protected], or visit dba.com.au

This article is brought to you by DBA