If you work in a general mechanical workshop and have encountered some types of failures on diesel engines that seem to have had mysterious, if not always inexplicable causes, you are not alone. While we all know how engines work, the fact is that many experienced mechanics have never had the opportunity to diagnose some types of engine failures that do not involve serious overheating of the failed engine and/or an obvious lack of lubrication in the failed engine.

In previous articles, we discussed some of these types of engine failures and their common causes, but there is one more type of engine failure, and particularly failures of diesel engines that are fitted with cylinder liners, whose causes are sometimes very difficult to diagnose or explain. These types of failures can occur on both wet and dry cylinder liners, and in this article, we will discuss some of the common, and some not so common, causes of cylinder liner failures in diesel engines. Let us start with this question-

Of course, not all diesel engines in light vehicles have cylinder liners, also known as "cylinder sleeves" and the principal reason for this is that it costs significantly less to produce a liner-less engine. However, the higher production costs of diesel engines with cylinder liners are largely offset by increased reliability and vastly reduced repair costs when compared to those of liner-less engines.

Increased reliability stems from the fact that cylinder liners are typically made from metal alloys that contain larger percentages of highly friction-resistant materials such as nickel and graphite than is possible to include in a liner-less engine block. Thus, cylinder liners can be made to be not only more wear-resistant than conventional cylinder bores, but liners can also be machined to more precise tolerances and surface finishes than is possible to achieve in liner-less engine blocks that flex and deform under high loads.

Moreover, using cylinder liners greatly increases both the dimensional stability and wear resistance of a diesel engine's cylinders, but by how much depends on several factors, not the least of which is whether the liners are of the wet or dry type. Both wet and dry liners have advantages and disadvantages, so before we get to the specifics of why cylinder liners fail, let us look at the differences between the two main types of cylinder liners. Let us start with-

Dry Liners

Dry liners are so-called because when they are fitted to an engine, their outside surfaces are in direct contact with the material of the engine block. These types of liners use a variety of sealing methods to not only contain combustion gasses from escaping into the clearance between the engine block and the liner but also to prevent oil and coolant from seeping into the cylinder.

While dry liners are generally cheaper and easier to fit than wet liners, the biggest drawback of dry liners is that an engine block requires extremely precise preparation before fitment of the liners to-

In fact, poor engine block preparation and improper fitment of dry liners are arguably the most common reasons why dry cylinder liners fail.

Wet Liners

Unlike dry liners, the largest parts of the outside surfaces of wet liners are in direct contact with the engine coolant. This has several distinct advantages over dry liners, not the least of which is the fact that both heating and cooling of pistons are almost 100 per cent uniform, which in turn, greatly reduces, if not eliminates, the possibility of pistons and rings wearing unevenly.

However, despite the obvious advantages of wet liners, the single biggest problem with these liners is the fact that engine blocks with wet liners are considerably less rigid than liner-less engines. As a result, wet liners require multiple seals against the engine block to prevent coolant and oil from entering the cylinders.

Moreover, fitting multiple seals require specific amounts of lubricant to ensure the seals expand as intended. In addition, fitting wet liners successfully also requires a) a gentle touch to prevent damage to the seals and b) insertion of the liner into the engine within a certain period to prevent the seals from expanding to the point where fitting the liner into the engine would damage or even destroy the seals.

Put differently, this means that the wet liner must be in its final position in the engine block before the seals start to expand since the expansion of the (undamaged) O-ring type seals is the only thing that prevents coolant leaks into the cylinders, which begs this question-

It turns out that many things could wrong, but for the purposes of this article, we will assume that the cylinder liner failures we will discuss here did not occur on liners that were installed by a professional, expert engine rebuilder. Instead, we will assume that the failed liners were installed on a DIY basis by a non-professional engine rebuilder who did not know that cylinder liners are not created equal.

For instance, while the dimensions of OEM or OEM-equivalent cylinder liners very rarely (if ever) deviate from design specifications by more than a few microns, many cheap, aftermarket cylinder liners frequently deviate from design specifications by several hundredths of a millimetre. Worse, though, this writer once encountered unbranded cylinder liners that differed in length by as much as two-tenths of a millimetre, which is more than enough to crack or fracture the liners when a cylinder head is bolted down.

We could list the many possible (and common) defects of cheap unbranded cylinder liners here, but given the limited scope of an article such as this, the list is far too long. Instead, we can do the next best thing, which is to discuss some actual examples of the types of cylinder liner failures you are most likely to see in a general mechanical workshop, starting with-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

This image shows a cylinder liner on which the flange had been torn off completely, which is arguably the most common failure on both dry and wet cylinder liners in modern diesel engines.

While there are many possible causes for this type of failure, they can be summarised by saying that all such failures stem from bending moments that are in their turn, caused by careless handling before installation, as well as improper installation procedures in general, and poor surface preparation, in particular.

Consider the self-explanatory examples of common causes below-

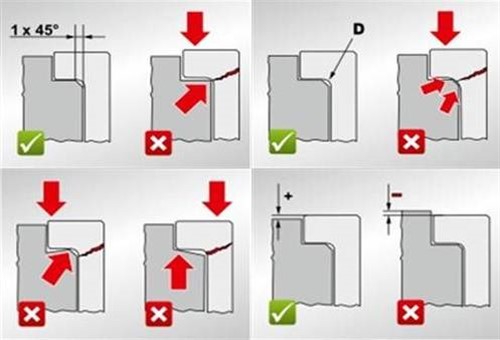

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

Before we get to specifics, it might be worth mentioning that in many cases, the flanges on one or more cylinder liners are already broken off by the time the cylinder head(s) are placed in position for tightening. There are two main reasons why these failures often go undetected during engine assembly; the first is because-

So in practice, many DIY or non-professional diesel engine rebuilders assume that the flanges’ mating surfaces in the engine are still flat and that their depth is still uniform around their entire circumference. This is, however, very rarely the case on high-mileage common rail engines, and very few, if any, cylinder liners survive the process of torquing a cylinder head down if the mating surfaces in the engine block are in a less than perfect condition, so let us look at the above panel of examples in some detail-

The example in the upper left corner of the panel shown above shows the location and dimensions of a critically important chamfer that is designed to allow both the engine and the cylinder liner(s) to expand freely, while preventing contact between the engine and the liner when both are in their expanded states, at the same time. However, this chamfer is only effective when the engine and cylinder liner flanges mate at exactly right angles over the entire circumference of the contact area. As a practical matter, it is helpful to remember that deviations in the mating area of as small as 2 thousandths of a millimetre are enough to break the flange off of a cylinder liner in some engines.

Nonetheless, while poor mating is a common cause of broken liner flanges, there are other possibilities, so let is look at-

The use of some aftermarket cylinder head gaskets

Over extended periods, small variations in the thickness of some gaskets can induce fatigue fractures as a result of cyclical changes in the pressure pattern a substandard gasket exerts over the circumference of the liner flange(s)

Failing to adhere to recommended or specified tightening and/or torquing of cylinder head bolts

In most cases, this can deform the cylinder head to the point where unequal loads on liner flanges cause them to break off- even in engines on which the mating surfaces are perfectly parallel and square

Incorrect machining of the pressure-relieving chamfer in the engine block

While a chamfer that is too small will cause pressure-induced failures of the flanges, a too-large chamfer reduces the flanges' load-bearing capabilities, with flange failures being the inevitable result

Insufficient protrusion over the block surface

In all modern diesel engines, the cylinder liners are locked in place by a combination of uniform clamping forces acting on the flange surface(s), liner seals that are in good condition, and the liners being of the correct length.

Thus, if liners are not too long, but the clamping force from the cylinder head is insufficient or unequal, the cylinder liners begin to execute a pendulum-like motion as the pistons move up and down in them. While this kind of movement can damage the O-ring seals at the bottom ends of the liners, this kind of motion is far more likely to break the flanges off the tops of the liners before the seals are damaged.

The use of sealants under the liner flanges

Using any kind of sealant under liner flanges might sound like a good idea to most non-professional rebuilders, but using sealants have two possible effects. The first is that it might increase the distance by which the liners protrude over the engine block, which will almost certainly cause the flanges to break off when the cylinder head is bolted down.

The second problem sealants have is that many of them shrink and/or degrade over time. Therefore, while the flanges might not break off immediately, they will certainly break off when the sealant shrinks to the point where the liners begin to execute a pendulum-like motion because of the reduced clamping force(s) acting on them.

Excessive installation pressure

Since dry liners are in full contact with the engine block, it is crucially important that the engine surfaces they bear on are perfectly cylindrical and free of deformations. In practice, deformations in the engine block of as small as 2 -3 thousandths of a millimetre are big enough to increase the installation pressure to the point where the flanges of dry liners may break off as they are pressed into place, which brings us to-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

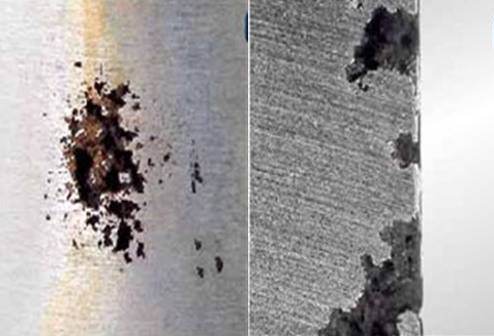

The image on the left in the above panel shows a view of a cylinder liner that appears to have been perforated by corrosion, while the image on the right shows a close-up view of what appears to be the progress of rust/corrosion through the wall of the same cylinder liner.

Collectively, these two images illustrate the destructive effects of cavitation, a process of material erosion that differs from material erosion caused by simple corrosion. In practice, rust or corrosion is a process in which a metal is dissolved by oxygen, while cavitation involves a process in which a metal, the material of the cylinder liner, in this case, is violently torn apart molecule by molecule. Moreover, while rust and corrosion can be prevented or stopped from progressing by using suitable additives in the coolant, cavitation is a process that is largely linked to the mechanical properties of the engine/cylinder liner combination. Let’s look at how cavitation starts and progresses in some detail-

Cavitation occurs as the result of several factors that combine to induce high-frequency vibrations in the wall of the cylinder liner. This typically occurs where the liner’s wall is subjected to the lowest bearing pressure from the piston as it moves between TDC and BDC and in a perfect engine, these vibrations would be damped out or absorbed by either the crankcase or the cylinder head(s). However, since no engine is perfect, the walls of cylinder liners in some engines can and do begin to vibrate so severely under some operating conditions that the engine coolant is driven off the surface of the cylinder liner, thus preventing effective contact between the coolant and the cylinder liner wall.

Moreover, the vibrations of the cylinder liner wall induce vibrations, or more precisely, pressure waves, in the coolant, and under some conditions, the coolant can be prevented from contacting the cylinder wall at all. Nonetheless, in most cases, the coolant is driven off the cylinder wall only very briefly when a vibration cycle peaks, and it is at these moments when small vapour bubbles form in the spaces between the cylinder wall and the coolant. At this point, and depending on the frequency of the vibration, as well as the strength of the pressure waves in the coolant and the pressure in the cooling system, one of two things can happen.

The first is that the vapour bubble is driven back into the coolant when the cylinder wall bounces back at extremely high speed, or, the vapour bubble can implode. When the vapour bubbles implode, the coolant (that had been displaced by a vapour bubble) rushes back to fill the space left by the bubble at speeds that can exceed several thousand metres per second.

Under these conditions, the force of the inrushing coolant on the wall of the cylinder liner is sufficiently powerful to tear molecule-sized bits of material out of the liner’s surface. If the condition occurs often enough over a sufficiently long period, the cavitation process can eventually perforate the wall of the cylinder liner as in the example shown above. It is important to note that as the erosion of the liner’s wall increases, the effect of the implosion of vapour bubble increases as well since the size of the vapour bubbles increase in an (almost) linear relationship to the size of cavitation sites.

Therefore, as a practical matter, once a process of cavitation starts, it accelerates as it progresses until the cylinder wall is perforated- which is always the first time we become aware that cavitation had been present in the engine at all, which begs this question-

Although cavitation on cylinder liners is often the direct result of poor engine design and a lack of structural strength in many diesel engines, several other causes can either induce excessive vibration in cylinder liner walls or contribute to the progression of cavitation once it starts. Let us look at some of the principal causes in some detail-

Fitment of incorrect pistons and/or incorrect cylinder liners

In this context, “incorrect pistons” can include reusing old pistons that are worn beyond a critical point, while “incorrect liners” can include using liners with incorrect inside diameters, liners that are too long or too short, or liners that have not been finished and/or honed to recommended surface finishes.

Incorrect liner fitment

This could include using shims, seals, sealants, or spacers under liner flanges where these are neither required, nor recommended, or poor surface preparation of the contact area between the engine block cylinder liners’ flanges.

Insufficient corrosion protection in the coolant

Note that one of the main functions of anti-corrosion additives in any modern engine coolant formulation is to prevent the coolant from foaming- which, if it occurs, prevents effective contact between the foaming coolant and the walls of cylinder liners. Under these conditions, vibrations in the cylinder walls that might not have been harmful had the engine coolant performed to specs, might “exploit” weaknesses in the shear strength of the coolant. Put differently, this means that foaming coolant can induce the process of cavitation through the presence of bubbles caused by foaming.

Insufficient pressure in the cooling system

Since the function of the pressure in a cooling system is to prevent the coolant from boiling, it follows that a lack of pressure will cause the coolant to start boiling at localised spots in the engine at very low temperatures. As a practical matter, boiling liquid has the same effect as foaming coolant, in the sense that boiling coolant also forms bubbles that can reduce the shear strength of the coolant to the point where cavitation becomes possible.

Engine running too cold

An insufficient operating temperature causes a cascade of effects, all of which can induce cavitation in most diesel engines either on their own or in combination with one or more other effects. Below is an example of such a cascade of effects-

1) The engine cannot build sufficient pressure in the cooling system.

2) Insufficient pressure in the cooling system means the coolant does not expand, which can seriously affect the circulation of the coolant.

3) A lack of coolant circulation can cause localised hotspots in cylinder heads and/or cylinder liners, which can in their turn, damage cylinder head gaskets or cause uneven wear of pistons, piston rings, and/or cylinder liners.

4) A low or insufficient operating temperature prevents the pistons from expanding to their most efficient diameter, which creates excessive piston to cylinder wall clearances. This, in turn, almost invariably induces excessive vibrations in the cylinder liners that in their turn induce the erosion of cylinder liner walls through the process of cavitation, which leaves us with this-

One other major cause of cavitation on cylinder liners is the poor quality of some aftermarket liners. Typical shortcomings revolve around defects in both materials used and manufacturing processes, but the problem with these kinds of issues is that a simple visual inspection will generally not reveal these kinds of defects.

In most cases, faults in materials can only be detected through advanced metallurgical tests in specialised laboratories, but given that these kinds of tests usually cost a lot more than even a full engine rebuild. Therefore, the best thing to do is to avoid using aftermarket cylinder liners altogether if there is any doubt about the quality of any cheap or unbranded cylinder liner(s).

In practice, using parts supplied by vehicle manufacturers and/or reputable dealers in aftermarket parts remains the most effective method of preventing the premature failure of critical parts like pistons, rings, and cylinder liners.

However, non-professional engine rebuilders can install even the best parts improperly or incorrectly, and while we as professional technicians cannot do anything about that, knowing what the effects of installing critical parts incorrectly or improperly looks like often goes a long way towards being able to identify the root cause(s) of diesel engine failures.