While it is important for technicians to know as much about as many aspects of car repair as possible, the days when every technician knew everything about everything are long gone. Modern cars have become too complex for any single person to know everything about everything that makes a particular car run, and this is especially true of transmissions and their control systems. If you are an experienced technician, but not a specialist in transmissions, this guide will briefly discuss DSG (Direct Shift Gearboxes) with reference to what they are, how they work, what their advantages/disadvantages are, and why they fail, starting with-

NOTE: Note that the terminology used to describe direct shift transmissions varies widely between automotive markets, which can cause confusion when the same thing is referred to by many different names. For this reason, this guide will use the term “dual-clutch transmission” throughout to avoid misunderstandings and confusion.

Be aware that although VAG group vehicles are the predominant users of dual-clutch transmissions, other manufacturers that include (among others) BMW, Ford, Mitsubishi, Smart, Porsche, and Hyundai also offer the technology on some of their products, albeit under different names. For instance, Ford calls their offering “PowerShift”, Audi calls theirs “S tronic”, while BMW and Porsche call their versions “DTC” (Dual-clutch Transmission), and “PDK” (Doppelkupplungsgetriebe), respectively.

Nonetheless, all of these offerings work in exactly the same way as the original DSG designs that were first used by Volkswagen in 2003. Note that although some versions/variants of dual-clutch transmissions use dry clutches, and others use wet clutches, the basic operating principles on all versions are the same regardless of whether a given version offers six, or seven gear ratios, or the transmission is mounted transversely or longitudinally in the vehicle.

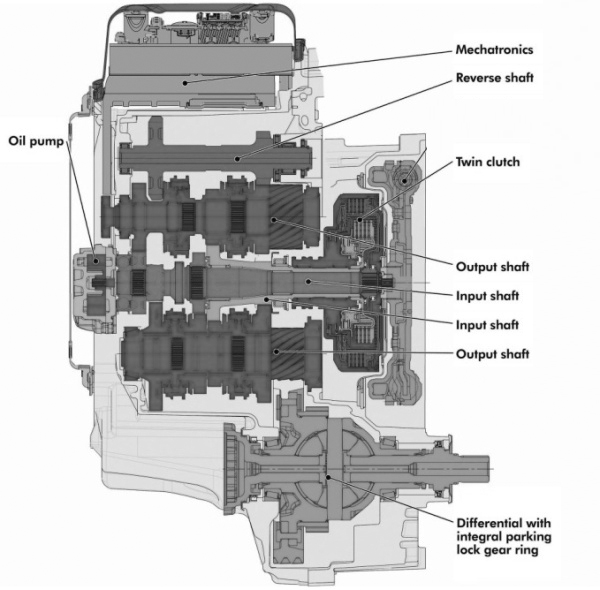

In simple terms, a dual-clutch transmission is made up of two automated manual transmissions and two clutches, in which each transmission is served by a different clutch. Unlike conventional manual transmissions that have only one primary and one secondary shaft, and where moving gears on the primary shaft to different positions on the shaft establishes different gear ratios, a dual clutch transmission has two primary shafts. Note though that in a dual-clutch transmission, the gears on only one primary shaft acts on the solid secondary shaft at any given time, since only one clutch is engaged at any given time while the vehicle is in motion.

Note that dual-clutch transmissions should not be confused with SMT (Sequential Manual) transmissions. While the performance in terms of the speed at which gear changes are accomplished is vastly superior to even the most refined manual transmissions, these designs use a single computer-controlled clutch to decouple the engine from the transmission during gear changes, which interrupts the flow of engine power to the driving wheels. Dual-clutch transmissions as we know them today were developed out of SMT technology, and for the most part, modern dual-clutch transmissions can deliver almost seamless acceleration.

In practice, the number of ratios on any given dual-clutch transmission is divided between the two primary shafts, with one shaft holding the odd gears, i.e., 1st, 3rd, and 5th gear, while the other holds 2nd, 4th, and 6th gear, and depending on the version and application, reverse gear as well. Note that on versions that have seven ratios, 7th gear will be on the shaft that holds the odd-numbered gears. Note though that gear selection can be either fully automatic, in the same way that a purely automatic transmission selects gears, or manually, in which mode the driver can change gears at will, usually by using “paddles” that are mounted behind the steering wheel.

Although fewer mechanical components are involved in gearshifts in dual-clutch transmissions than in purely automatic transmissions, the process nevertheless involves complex algorithmic calculations that are in some ways more complex than those used in purely automatic transmission control systems. Nonetheless, while these calculations differ between applications, the basic process of shifting gears on a dual-clutch transmission is the same for all applications, a somewhat simplified description of which follows below, starting with-

Upshifts

If the transmission is in neutral, both clutches are disengaged, and since dual-clutch transmissions do not have conventional clutch pedals, the ECU (Engine/Electronic Control Unit) uses input data from sensors such as the engine speed -, and throttle position sensors (among others) to calculate appropriate fuel delivery and ignition timing strategies when say, 1st gear is selected manually.

Based on the detected rate of movement of the throttle pedal, the ECU then engages the clutch that serves 1st gear while at the same time selecting 2nd gear on the inactive primary shaft, which remains inactive since the clutch that serves that shaft is kept disengaged. When the driver selects 2nd gear, the ECU disengages the clutch that served 1st gear, and since 2nd is already selected, the ECU merely engages the clutch that serves 2nd gear, which has the practical advantage that gear changes can be performed in less than 10 milliseconds, as is the case on some VAG-group applications.

This process is repeated for all gear ratios. While the vehicle is accelerating in 2nd gear, 3rd gear is already selected, and so forth, which means that in practice, the next higher gear is always already selected, and changing to that next higher ratio is accomplished by disengaging one clutch, and engaging another in a process that is measured in milliseconds. Note though that while the speed at which actual gear changes are accomplished does not vary, regardless of whether the transmission is in manual or automatic mode, shift points do vary based on which shift mode – “Economy” or “Sport” is selected when the transmission is in automatic mode.

As a practical matter though, the dual-clutch transmission’s control module has the ability to both predict which gear is the most likely to be selected next, and to select that gear on the inactive primary shaft. The next higher or lower gear will then remain selected on the inactive primary shaft until a manual input from the driver occurs, or, until the ECU commands a gearshift if the transmission is in automatic mode.

During normal operation in manual mode, the driver can select when to shift gears and the ECU still controls the clutches, but as a safety measure, the ECU can either prevent a gear shift, or force the transmission into the next higher gear if a gear shift can or will cause the engine to over-rev. One example of this would be if a driver attempts to drive at 75 km/hour in first gear; in this case, the ECU would force the transmission into 2nd gear to prevent damage to both the engine and the transmission.

Downshifts

Downshifts follow the same pattern, but with the difference that the ECU matches the engine speed with the selected lower gear, which eliminates the surging and jerking that often accompanies downshifts with conventional manual or purely automatic transmissions at high engine speeds. Note that while most dual-clutch transmissions can only down shift one gear at a time, some designs have the ability to skip one, or in some cases, even two or three gears while shifting down.

The principal advantage of dual-clutch transmissions is that they provide the same engine power delivery characteristics as a conventional manual transmission, but with the convenience that comes with a conventional automatic transmission. In practical terms, this means that acceleration is generally near seamless. In fact, the highly refined dual-clutch transmissions on most high-end applications deliver gear changes that are all but undetectable, and in many cases, the acceleration on these applications is as smooth as that delivered by a CVT (Continuously Variable Transmission).

One further advantage is that dual-clutch transmissions deliver a measureable increase in fuel economy over conventional automatics, since there is no slippage between the engine and the transmission. However, how much fuel can be saved depends on driving style, vehicle usage, and the selected operating mode, but for the most part, fuel savings of up to about six percent can be achieved over conventional automatics.

Provided the dual-clutch transmission on any given application is fully functional and free of defects, there are no major disadvantages to these transmissions, except for the fact that under some driving conditions, the ECU allows the active clutch to slip, which can greatly reduce the useful service life of that clutch. One example of this type of driving would be when the vehicle is “inched” along, such as when a vehicle is forced to move at below, say, a walking pace in heavy traffic. Under these conditions, the ECU will keep 1st gear engaged, but to prevent the engine from stalling, the ECU will allow the 1st gear clutch to slip until conditions allow the ECU to fully engage the active clutch.

Nonetheless, many drivers prefer a conventional manual transmission to a dual-clutch transmission because they feel that the combination of conventional clutch pedal and stick shift provides them with an enhanced sense of control over the vehicle.

While limited space precludes a full exposition on all the possible problems and issues that affect dual-clutch transmissions on all applications, there are nevertheless some issues that are more or less common to most designs. These could include one or more of the following-

Mechatronic failure

The term “mechatronic” is a generic term that is often applied to the control module of all dual-clutch transmissions. Essentially, it is an electronic control module that incorporates a mechanical valve body that strongly resembles the valve body on a conventional automatic transmission, and failure of, or defects in this hybrid control system is by far the most common cause of dual-clutch transmission issues. Note that high-end diagnostic equipment is required to extract fault codes from the mechatronic unit.

It should be noted that almost any failure or defect in the mechatronic unit will illuminate a warning light, and force the transmission into a failsafe, or limp mode that will persist until the fault is corrected. However, since the unit will also store fault codes that relate to the issue, these codes are invaluable diagnostic aids. For instance, if any codes are present that relate to any transmission related sensors, gear ratios, or unexpected/uncommanded mechanical engagements/disengagements, the root cause of the problem is almost invariably related to a failure of the mechatronic unit itself, as opposed to failures of the components that are identified in the code definitions.

Depending on the application, when some codes mention “Clutch Limits”, “Clutch Limits Reached”, or other wording that relates to the clutches, it is almost certain that the clutch friction linings have worn down to below a minimum allowable thickness. Note that while some manufacturers of dual clutches do supply repair kits, the only reliable remedy for worn clutches is to replace the entire clutch kit as an assembly. Be aware however, that installing a dual clutch requires both special tools and very specific skills. In fact, many, if not most manufacturers and suppliers of dual clutches will not honour a warranty claim if the installer had not successfully completed a training course on installing these clutches.

Special note should also be taken of the fact that while there are many self-proclaimed experts that advertise their ability to repair mechatronic units, the fact is that all of these specialists are limited in what they can diagnose and/or repair, since large chunks of the mechatronic’s programming is proprietary to the manufacturer of the affected application. Be aware therefore that if a repairer says the unit is “OK”, or that “No faults were found”, there is a very high likelihood that the repairer could not diagnose the root cause(s) of the failure because he was unable to access all of the unit’s programming. Replacement and proper integration of the replacement mechatronic is the only reliable, long-term solution to mechatronic failures.

Note that on some dual-clutch transmission variants, and especially the DQ250 variant used in many VAG-group applications, the partial or complete loss of reverse gear is usually caused by a failure of the mechatronic unit.

One of the functions of a mechatronic unit is to monitor the amount of wear on the clutch friction material, and to make suitable adaptations to the travel of the clutch actuator to compensate for this wear. However, one of the biggest causes of gearshift issues on dual-clutch transmissions is the failure of the mechatronic unit to adapt the clutch actuator’s travel to compensate for clutch wear, which can cause problems with gearshifts that are largely similar to the problems that occur when a conventional clutch fails.

In many cases though, performing a simple clutch adaptation with a high-end scan tool will resolve the issue, unless there are trouble codes present that refer specifically to the clutches being worn.

On some variants of dual-clutch transmissions, the clutches are housed in a separate enclosure where they are bathed in oil with a very specific formulation. While this arrangement has several advantages, the biggest problem with it is that when cross contamination of the transmission lubricant and the oil bathing the clutches occurs, both the clutches and the transmission can be damaged. In fact, this particular problem was so severe (and common) on some wet-clutch designs that several manufacturers abandoned the wet-clutch principle altogether.

Although noisy bearings are a relatively common feature of most dual-clutch transmissions, the transmission is unlikely to fail catastrophically because of it. In fact, most designs will work fine for several thousand kilometres after one or more bearings have become noisy; however, as with all mechanical failures, the problem should be rectified as soon as possible.

Blaming excessive vibration on the dual-clutch assembly is arguably the most common mistake many technicians make when they diagnose issues with vibration on dual-clutch transmissions, since excessive vibration is usually caused by issues with the dual mass flywheel. If the clutches were out of balance they are likely in the process of disintegrating, which would manifest as mechanical noises, failure to shift gears, failure to engage one or more gears, or in some cases, the transmission being locked into a limp mode.

Like conventional automatic transmissions, dual-clutch transmissions are fitted with safety cutout switches that prevent the engine from being started unless the transmission is in neutral. Failure of, or defects in this switch and/or its associated wiring will cause a no-start condition, which may or may not be accompanied by a warning light and a trouble code, depending on the exact nature of the problem.