Wouldn’t it be nice if someone published an article about electrical and electronic diagnostics that does not take deep dives into the laws of electrical theory, explain how atoms move around within atoms to create high and low energy states, or worse, try to explain how solid-state relays switch between "ON" and "OFF" states without moving parts?

It would indeed be nice because, for most of us who do not specialize in electrical or electronic diagnostics, these topics border on the arcane, if not the dark arts. However, the good news is that it is possible to diagnose and repair many, if not most, electrical issues without having to have dozens of electrical laws, theorems, and formulas at our fingertips, so to speak. Note that this is not the same as saying that having at least a working knowledge of electrical theory is not important: far from it. A sound knowledge of electrical theory is and remains the bedrock of electrical diagnostics, but this article is not about electrical theory- this article is about providing tips and pointers to help you diagnose and fix the electrical issues on the vehicle you have in your bay now, without referencing electrical laws and theorems. Before we get to specifics, though, let us start by answering this question-

Put simply, there is always room for more articles on most topics, and even more so given the imminent implementation of the Competition and Consumer Amendment (Motor Vehicle Service and Repair Information Sharing Scheme) Act 2021, aka, the Mandatory Data Sharing Law, which is certain to change the way the independent car repair industry functions in meaningful ways.

Although it is unlikely that all, or even most independent workshops will be run off their feet from the first day the law becomes operational, there is no telling how long it will take before independent establishments begin to see significant numbers of vehicles that are under warranty. More to the point, though, this writer has made the point in previous articles that diagnostics at the dealership level differs from what the independent repair industry is used to doing in several important and meaningful ways.

The above essentially means that independent mechanics will soon be expected to diagnose, and repair faults in systems they had never seen or worked on before, and in terms of pure complexity, telematics systems in all their various forms are probably at the top of the pile. However, at the bottom of the complexity scale we will still have the usual suspects; failed indicator lights, dim headlights, non-working brake lights, power windows that get stuck, simple wiring issues, etc. etc., albeit on new vehicles that are covered by warranties.

On a purely practical level, however, we in the independent repair industry have several things going for us. The first among these is the fact that under their metal skins, all cars are essentially the same.*

* Note that hybrids and electrical vehicles are excluded from this statement, but we will provide some common sense diagnostic tips and tricks for these categories of vehicles in future articles.

For instance, although the technical implementation of some systems may differ between vehicle brands and between models from the same brand, the law will oblige manufacturers to provide us with all relevant technical information we require to diagnose and resolve issues on new vehicles, although in practice, it remains to be seen how manufacturers will fulfil this obligation. However, while having access to technical information will be extremely helpful, the format in which the information is presented often has its own issues, which we will talk about later on.

In addition, the basic technology that makes new cars work also make older vehicles work, although there might be some improvements and tweaks in place on newer vehicles. Nonetheless, and apart from tacked-on systems like telematics and some ADAS-related features, the basic ABS systems on new cars work in the same way as the ABS systems on older vehicles do. The same is true for fuel and engine management systems; fuel trims and volumetric efficiency values remain valuable diagnostic clues/aids. In practice, this means that the process of diagnosing most issues on new vehicles will largely remain unchanged for the foreseeable future, but before we get to some specifics, let’s look at some of-

No doubt having the right tools for the job, and applying those tools effectively makes life a great deal easier, but do you really need tools like sensor simulators, relay testers, current probes, micro amp clamps, and oscilloscopes if you are not an expert that specializes in electrical diagnostics?

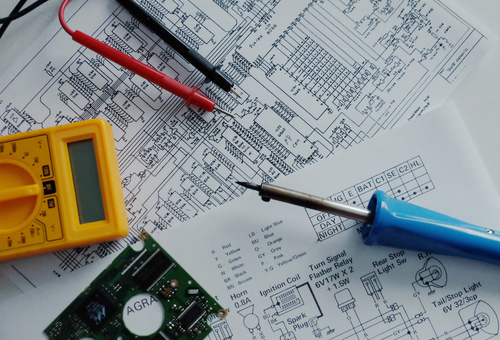

Frankly, no, you don't need the above tools, or at least, not all of them because a high-end generic scan tool and a good digital multimeter will let you diagnose at least 80 per cent of all simple electrical issues on new vehicles. Note that the operative word here is "simple", which in this context, refers to the vast amount of global or generic fault data that high-end generic scan tools can access without any trouble.

For instance, (almost) all generic OBD II data can be accessed with a high-end generic scan tool if you use all ten modes on the tool. Moreover, if you add to this a dedicated, but modestly priced tyre pressure sensor diagnostic tool, and perhaps an equally modestly priced relay tester, you have just about all the tooling you’d need to diagnose many, if not most electrical issues on new vehicles.

However, tools come in different forms, with information perhaps being the most effective tool any of us can have in our toolboxes. So while the Competition and Consumer Amendment (Motor Vehicle Service and Repair Information Sharing Scheme) Act 2021 will now give us access, albeit at a price, to information that was largely unavailable to us before, there is one form of information that even dealerships have no access to.

Here we are talking about Technical Service Bulletins, which typically only become available when pattern failures begin to manifest on vehicles that are a few years old*. In a previous article, titled “Technical Service Bulletins: The Gifts That Keep on Giving”, we provide details on how valuable technical service bulletins can be to independent mechanics, but the problem is that even dealerships sometimes encounter electrical issues on new cars that have not been addressed by manufacturers.

*There are exceptions to this rule. In a few cases, this writer had found TSBs that relate to electrical issues on new vehicles as soon as three weeks after the launch of a model. Nonetheless, if a technical service bulletin is not available, the next best option is to identify the problem by using-

If you have never worked on new vehicles, or at least, vehicles that are still under warranty, you will be amazed at how prevalent electrical issues are on the products of all manufacturers. However, it’s not as if manufacturers intentionally build these faults in their vehicles, but the fact is that much of the process of assembling new vehicles is done by people who sometimes make mistakes.

This writer had gained some firsthand experience of these kinds of mistakes when he worked in a BMW factory in a foreign market nearly thirty years ago. Of course, the vehicles of that era were not nearly as complicated as the vehicles of today, but based on recent personal experience, many assembly mistakes still occur across all manufacturers today. In case you were wondering, here are some examples-

There are many other examples of sloppy and/or incorrect assembly procedures that sometimes make it past several layers of quality testing/checks, but the few instances/examples listed above should suffice to demonstrate that the electrical systems of new vehicles are sometimes built to fail, albeit not always intentionally or by design.

So let’s say that a new vehicle a customer had bought two weeks ago is now in your bay because the customer believes that an independent workshop can fix say, the intermittently failing windscreen wipers, quicker and cheaper than a dealership can, regardless of the cause of the issue. Where do you begin the diagnostic process, given the fact that the vehicle is new to you?

Many of us could be forgiven for breaking out in a panic-induced sweat, but when one views such a situation objectively, there is no real difference between how one should approach this particular issue, and a similar issue on an older, but familiar vehicle.

One would still gather as much information from the customer as one can about the condition. Things like when it happens, how often it happens, or if it only happens during some operating conditions. One should also verify that the fault actually exists using the information given by the customer, and, of course, attempt to replicate the issue under the conditions as described by the customer.

On a more practical level, however, one should obtain as much information about the affected system/part/component as one can as a first step. While fault codes might have some diagnostic value, the kind of information one needs would be the relevant section in an official repair manual, but most importantly, one needs a wiring diagram of the affected system.

Realistically, it would be almost impossible to diagnose an intermittent failure (of the wipers) without a wiring diagram that illustrates the technical implementation of the affected system. This is particularly true if our hypothetical problematic wiper system is controlled by a dedicated control module because a wiring diagram will also illustrate possible integrations of the wiper control system with other control systems/modules.

Finally, a wiring diagram makes it possible to get a general overview of the overall layout of the affected system, and if, and how, this system is integrated into other, perhaps only peripherally associated systems. This last point is crucially important because while repair information supplied by the manufacturer might include pinpoint tests and/or diagnostic trees, the problem with pinpoint tests and diagnostic trees is that they are rarely designed by car manufacturers to be the most efficient way to test electrical systems.

As a matter of fact, these kinds of tests are almost always designed to save costs by leading dealership technicians to a resolution of a problem as quickly as possible, as opposed to allowing technicians to investigate the cause(s) of a problem by explaining what it is that is being tested. For example, a pinpoint test can take you through ten or twelve difficult and time-consuming “YES” or “NO” steps, only for step thirteen to tell you to check fuse say, #56 if the answer to step 12 is “NO”, and to replace the fuse if it is blown or melted- which, incidentally, will resolve the problem more often than not.

This is an important point to keep in mind because logic and common sense dictate that since devices such as fuses and fusible links are designed and intended to protect circuits, checking the condition and operation of these devices before embarking on a time-consuming series of pinpoint tests should be the first step in a diagnostic process.

Therefore, if you are going to be working on a new car or on one that is unfamiliar to you, the obvious thing to do would be to obtain and use a wiring diagram, because it will allow you to formulate and streamline a diagnostic process. Put differently, this would be a process that does not (necessarily) involve taking the car apart to access wiring that could be tested with less trouble such as, for instance, checking, and replacing fuse #56 before removing the instrument cluster to perform step 12 in an OEM-supplied diagnostic tree.

Note that the above should not be taken to mean that manufacturer-supplied repair information should be disregarded; far from it. In fact, we would not be able to work on new vehicles without access to OEM-level service and repair information, but as we said earlier, the format in which information is provided, such as pinpoint tests and diagnostic trees, can often make finding the cause(s) of issues more difficult than it needs to be.

So while these tests can be useful, many of us have fallen into the trap of testing and verifying continuity in all manner of circuits only to find that when we switch on a system or consumer, the system or consumer still does not work, or does not work as expected. Thus, if you suspect that you will be spending a lot of time following a diagnostic tree or a series of pinpoint tests, you may want to consider the following “rule”-

There are many ways of load testing circuits, but if you are going to be doing this on a new vehicle, you'll want to remove as few trim panels or other impediments as possible to avoid damaging some panels or causing rattles and squeaks that can take more time to find and fix than the original electrical problem did.

Moreover, if you don't have access to expensive tools like a microamp clamp, relay tester, or sensor simulator, you can easily rig up your own test equipment with jumper wires of the same thickness as the suspect circuit and some brake light bulbs. Depending on the circuit's current (amperage rating), you can use one, two, or even three bulbs, but be sure to connect them so that when you remove one bulb from the setup, the others will still work to simulate the load the circuit is intended to carry.

The object of this test is to verify that the suspect circuit can (or cannot, as the case may be) carry or conduct the current it is intended to conduct over its entire length. Thus, if you substitute your test circuit for the original circuit and the appropriate number of bulbs light up when you activate the system you are testing, but the consumer, such as a blower motor, does not work or works slower than it should, the OEM circuit is defective in some way.

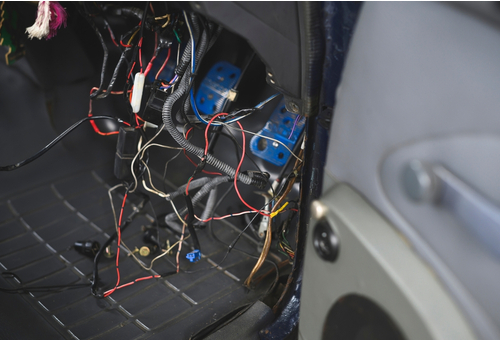

Typical causes of such defects, and especially on new vehicles, include poor ground connections, improperly engaged connectors, incorrect or sloppy routing of harnesses that put a strain on connectors and wires, as well as poor underbody sealing that could cause water to penetrate the passenger cabin to create short circuits under carpets.

Also, bear in mind that sloppy assembly procedures in the factory can, and do cause a variety of [loss of] communication issues across one or more, or even multiple serial communications systems in a new vehicle. Sadly, these kinds of issues can be extremely challenging to diagnose and resolve, because, except for using a thermal camera, there are no quick and easy ways to locate poor connections, damaged wiring, or connectors that may not be latched properly, which brings us to probably the most important challenge we will face on new vehicles, this challenge being-

As the name suggests, gateway modules are in effect, gateways that secure various critical systems on most new vehicles against unauthorised access. When Fiat Chrysler Automobiles (FCA) first introduced gateway modules in some of their products a few years ago, the primary function of these gateway modules was to prevent hackers from assuming control over the vehicles’ security systems.

While this move was prompted by the famous incident of a couple of hackers starting and controlling a Jeep Cherokee remotely, the use of gateway modules was soon expanded to prevent unauthorised reprogramming of vehicles, in addition to protecting vehicles’ security systems. However, during the past two or three years, almost all major car manufacturers have begun incorporating gateway models into almost all of their products, and in some cases, the gateway modules are so efficient that all access to all systems on many vehicles is protected against even legitimate requests for access to fault data.

In practice, this means that while almost all new vehicles are protected by gateway modules today, the level of protection differs between some manufacturers. For instance, on some protected vehicles it may still be possible to read basic fault data with an unsecured scan tool, although it may not be possible to clear some, or any fault codes, while on other vehicles, all access, including access to fault data, is blocked unless a scan tool is registered.

As a practical matter, FCA brands include Alfa Romeo, Fiat, Chrysler, Jeep, Dodge and RAM branded vehicles, and while we in Australia can register some of our scan tools* to gain full access to these vehicles, it remains to be seen how carmakers such as Ford, Nissan, Toyota, Mazda, and almost all others will implement access to their products.

* Note that the current list of scan tool brands that can be registered to access FCA vehicles is rather limited. Contact the manufacturer of your scan tool for more details on how to register your scan tool(s).

Despite a diligent, hours-long online search, this writer was unable to locate accurate, verifiable information on how non-FCA vehicle brands will make it possible for us in Australia to access the systems on their vehicles. It seems likely that these manufacturers will establish in-house facilities to accomplish this, but as matters stand now. only one state (out of the fifty states) in the US market currently has legislation like the Competition and Consumer Amendment (Motor Vehicle Service and Repair Information Sharing Scheme) Act 202. Hence,non-FCA manufacturers in the US and other major automotive markets do not seem to be in any sort of hurry to share this information with anybody outside of the official dealer networks in these markets.

For the moment, though, and for what it may be worth, the Competition and Consumer Amendment (Motor Vehicle Service and Repair Information Sharing Scheme) Act 202 seems to favour the independent repair industry. Here are the relevant details of section 57DB of the Law, which deals with Safety and security information—supply to Australian repairers and scheme RTOs-

This section states that-

(1) A data provider must not supply scheme information under this Part that is, or includes, safety and security information for a scheme vehicle of a particular make, model and year unless:

(a) there are reasonable grounds, based on information provided by the Australian repairer or scheme RTO, to believe that the requirements covered by subsection (2) are satisfied in relation to the scheme information for that vehicle; and

(b) the Australian repairer or scheme RTO has provided the required declaration, or declarations, covered by subsection (3) in relation to that vehicle. (Italics added)

This section also states that-

(2) The requirements covered by this subsection are that:

(a) the safety and security information is solely for use by an individual or individuals:

(i) in the case of an Australian repairer—for the purposes of the Australian repairer’s business; or

(ii) in the case of a scheme RTO—for the purposes of providing an RTO course; and

(b) based only on personal information about the individual covered by subsection (6), the individual is a fit and proper person to access and use the safety and security information. (Italics added)

So, while the law seems to be in our corner, so to speak, we will have to wait and see how many hoops non-FCA manufacturers will make us jump through to gain access to the OBD II systems on their products via their secure gateway modules. What this writer does know, however, is that with all things legal, nothing is ever a sure bet so we’ll have to wait and see how this plays out in the real world, which leaves us with this-

We hope that this article has given you some new insights into the world of working on vehicles that are covered by warranties. As for electrical diagnostics on new vehicles, in particular, it helps to remember that a new vehicle is just that- a new vehicle that works in ways that we are already reasonably knowledgeable about.

The only real difference is that the technical implementation of some systems on new vehicles may employ tweaks and improvements over existing systems/implementations that could trip us up temporarily, but then again, we have lived through bigger changes and challenges than this, so we will no doubt live through learning to work on new vehicles, as well.