Electronic Parking Brakes are nothing new, they have been on some vehicles since the late 90’s but what was once a scarcely implemented technology is now commonplace on many new vehicles.

There have been over 100 million Caliper-integrated Electronic Parking Brake units produced to date by one major manufacturer alone!

Electronic Parking Brakes remove the connection between the driver and the park brake, much like fly-by-wire removes the connection between the driver and the throttle butterfly. Instead an electronic switch is used to activate and deactivate the system via a dedicated control unit on most systems.

What?

There are two main types of Electronic Parking Brakes; the Caliper-Integrated System, where the parking brake is part of the brake caliper assembly.

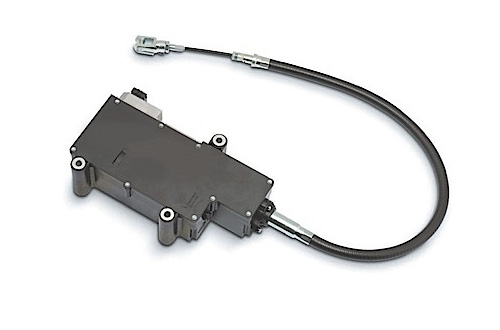

The other type is what is referred to as the Cable-Pull System, which motorises the conventional park brake system using a bi-directional motor by pulling on or releasing the cables.

The Cable-Pull System allows easier integration into existing production parts, given that it is an electronic system acting over an existing mechanical solution. The control units are often located under the vehicle or in the boot area, often with the provision for a manual release in the event of a failed motor.

The Caliper-integrated System also utilised a bi-directional motor, however instead there is one situated inside each caliper. The motor forces the caliper piston out in order to keep the rotor in a fixed position. These systems almost always use a gear reduction system in order to deliver such high torque from a small motor.

Why?

Electronic Parking Brakes are often another technology that is coined as ‘doing something for the sake of doing it’ however they do provide a few advantages.

Electronic Parking Brakes eliminate the need for brake cables and related components as well as making the manufacturing process easier as there is only one hydraulic and electrical connection to each rear brake system.

The other notable saving is weight, with one manufacture claiming a saving of 6kg through utilisation of an Electronic Parking Brake system.

Caliper-integrated Systems are often found on Audi, Ford, VW and many more makes of vehicle. It is not uncommon to see CAN to the brake caliper either, eliminating the need for a separate control unit.

Operation

On most vehicles, the parking brake is actuated by operating the switch on the dash/console area. On other applications the parking brake can be operated automatically by the vehicle in situations such as the transmission being put into the park position or when the drivers door is opened or seatbelt undone. (Other vehicle parameters are also assessed to avoid unwanted application of the handbrake while moving for example) The electronic parking brake system can also double as a hill-hold.

Other handy integrations include immobilisation of a vehicle to prevent theft, integration into the Anti-lock Brake system for slow speed traction control, vehicle braking in a hydraulic failure situation and automatic braking if a reverse system detects an obstacle!

In the Workshop - System Tricks

Having correct and up-to-date service information is imperative when working on Electronic Parking Brake systems.

Rear brake pad service or even caliper replacement on Holdens with the cable puller Electronic Parking Brake system is performed similar to a non-powered parking brake system. But if any parking brake cable or Electronic Parking Brake unit replacement is required, the Electronic Parking Brake will need to be put into service mode.

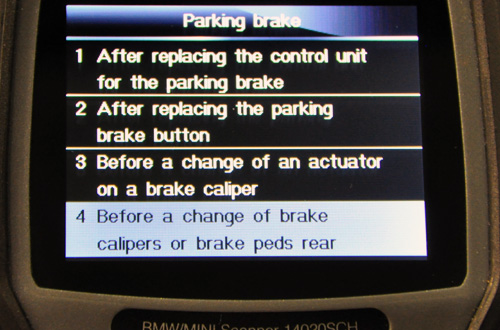

This can be done manually using the service port on the Electronic Parking Brake module and backing the motor off by hand, using the proper tool. A scan tool may also be used to get the Electronic Parking Brake assembly into service mode and is the preferred method. But after the cables are replaced, the Electronic Parking Brake needs to be tensioned and this can only be done using a scan tool following the specific reset calibration procedure.

Lexus has a similar manual release procedure available for their cable puller design, but again after the service work has been performed, a scan tool that will communicate with the Electronic Parking Brake module is going to be needed to finish the repair, and turn off the Electronic Parking Brake light.

Some BMW’s use a cable puller Electronic Parking Brake and the module is located in the boot. If anything gets spilled or the boot has a water leak, the Electronic Parking Brake module is in the low spot and can be damaged. This water intrusion can cause the Electronic Parking Brake module to freeze, seize up or turn on the Electronic Parking Brake warning light.

The BMW tool kit does supply the tool needed to manually release the Electronic Parking Brake if it will move (they are usually seized solid) and the owner’s manual explains how to perform a manual release.

These BMW Electronic Parking Brake motors also have a set of plastic gears that fail and wear. They are not available from BMW, but replacement gears are available online. The Electronic Parking Brake unit can be re-initialised manually after gear replacement by pressing the parking brake button three times with five-second intervals between pushes. The motor will try to release the brakes, then apply the brakes and finally release the brakes to complete the initialization. A compatible scan tool may also be used to perform this function.

Using a scan tool is typically the recommended method to retract the calipers on a Caliper-integrated system to their service position to allow rear brake service or pad replacement. The scan tool is then used again to exit the service mode and automatically adjust the pads to the correct clearance after the rear brake service is performed.

If working on some VAG vehicles with an integrated Electronic Parking Brake, not only will you need a scan tool to put the calipers into service mode and then re-initialise them, but you may also need to enter the actual brake pad material thickness!

The EPB system will use an algorithm to calculate the wear on the rear brake pads. This replaces the need for a pad wear sensor. Even if you have done the pad replacement properly, the brake wear warning light may stay on and trouble codes may be present until this brake pad thickness information is set into the Electronic Parking Brake module. So, make a quick measurement of the pad thickness just in case you need this information.

Many vehicles need software updates to fix issues that could cause either the Electronic Parking Brake to stick, drag, not release, or illuminate the Electronic Parking Brake light.

To name a few, Honda, Jeep and Subaru have a number of different updates to correct Electronic Parking Brake issues from false applications to brake drag.

Mazda’s also has a recall on their Electronic Parking Brake system. A sealing issue on the rear integrated caliper design may allow water to enter, causing corrosion. This corrosion can cause the caliper to jam or fail to properly engage.

Our Opinion

We think that working with a Caliper-integrated Electronic Parking Brake system actually makes life easier when carrying out brake services.

Do you agree? Have your say in the Mechanic.com.au Private Facebook Group (Members Only)