We all know that proper and effective air and fluid filtration is critically important to maintain the efficiency and durability of modern vehicles, but what we do not always realise or appreciate is that automotive air and fluid filters are not created equal. For example, while most branded filters meet or exceed the stringent performance standards set by car manufacturers and international regulatory bodies like the ISO and ASE, not all filters always meet these standards under our harsh and demanding local conditions.

Thus, given this fact, in this article, we will take a closer look at Fram air and fluid filters, which are designed and engineered to meet or exceed OEM requirements and standards under our harsh operating conditions. Before we get to specifics, though, we need to discuss one aspect of what makes our atmospheric conditions more demanding than the atmospheric conditions of most of say, Europe or most of the USA, this aspect being the fact that-

Although silica and silicates make up around 95 per cent of the Earth’s crust, our climate is too dry to keep the highly abrasive silicate dust from being lifted into the atmosphere by high winds. So even if we can’t see most of the dust, winds in the lower atmosphere carry extremely high loads of silica and silicate dust across all of the country.

So why is this important? It is important because unlike markets like Europe and much of North America where climatic conditions keep most of the dust from being lifted into the atmosphere, our local climate is too dry to do this. Therefore, Fram designs and engineers automotive filters that not only suit our local conditions, but also meet and/or exceed OEM specifications in terms of fit, form, and function even under our harsh and demanding conditions.

In practice, this means that the engineers at Fram have to create air and fluid filters that strike a fine balance between a filter’s rating, efficiency, capacity, durability, and cost. In fact, car manufacturers conduct regular audits of Fram’s design and manufacturing facilities to ensure that Fram produces air and fluid filters that consistently meet their stringent performance standards as well as the ISO9001 & IATF16949 standards. Such audits are critically important to ensure that new vehicles' warranties are not affected or voided if we fit Fram filters during a scheduled service or maintenance procedure.

Having said the above, and even though all Fram filters are backed by a comprehensive warranty against faulty workmanship and materials in their products, no automotive filter can trap and/or contain all solid particles. If automotive filters could do that, engines would be starved of air and fuel, as well as oil to lubricate moving parts, which is a self-evident truth.

In this regard, it is perhaps worth mentioning that a) since air filters have to let some air through to make an engine run, and b) that since abrasive silicate dust particles vary in size from sub-micron diameters to about 10 microns in diameter, a major, if not the leading cause of mechanical wear in engines is the presence of silicate and silicate dust in engine oil., which brings us to the topic of-

Until comparatively recently, oil filter efficiencies were expressed in microns: for example, if an oil filter had an efficiency rating of say, 80 per cent for particles of say 20 microns, it meant that the filter would remove 80 per cent of particles in the oil that were 20 microns in diameter. However, at the same time, this also meant that the filter would let all or most of the particles that were smaller than 20 microns through.

As a practical matter, such ratings were developed by letting some oil seep through a single flat sheet of filter paper, and this method worked well when one sheet of filter paper of a particular construction was compared to another sheet of paper of a different construction, but this method and its results were repeatable only within individual organisations.

In practice, filter manufacturers used proprietary filter papers, which meant that different filter manufacturers obtained different test results because filter paper/media differed from manufacturer to manufacturer. More importantly, though, since the design and construction of an oil filter, as well as the filter medium used in an oil filter affected its efficiency, this method could not test the efficiency of a completed oil filter under real-world operating conditions.

Other factors that influence the efficiency of oil filters include the flow rate of oil, the type and condition of oil in an engine, the oil pressure and intensity of pressure spikes after cold starts, and continual changes in the frequencies at which engines vibrate.

What was needed was a different way to test and rate oil filters, and to this end, Fram now uses a method that passes contaminated oil through a test filter multiple times, until the pressure differential across the filter reaches a pre-determined level. The test equipment also uses optical particle counters that count the number of solid particles in the oil before and after the filter, and based on this test, an oil filter is assigned a B, or Beta ratio.

As a practical matter, the B ratio is defined “… as the number of particles greater than a given size in the fluid upstream of the filter, divided by the number of particles of the same size found downstream of the filter. Particle numbers are determined by count, not weight”. [Therefore]”… A B10 value of 2 would mean that for every 1,000 particles greater than 10 microns found upstream, 500 particles greater than 10 microns passed through the filter. Since only half of the particles are removed, a B10 value of 2 indicates that the filter is 50% efficient for taking out particles larger than 10 microns." Source: https://www.fram.com/media/wysiwyg/resources/consumer_tech_docs/fluidfilterrating.pdf

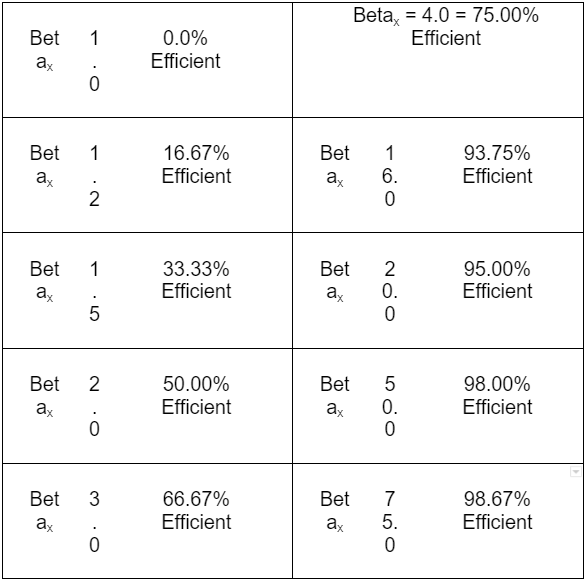

The table below lists some more examples of oil filter B ratios-

Source: https://www.fram.com/media/wysiwyg/resources/consumer_tech_docs/fluidfilterrating.pdf

The single biggest advantages of the way Fram tests oil filters are a) that the multi-pass method is repeatable any number of times for any oil filter, and b) that b ratios provide us as mechanics and technicians (and our customers), with an apple-to-apple comparison between oil filters made by different manufacturers for any given application.

However, despite the advantages of the way Fram tests and rates oil filters, the efficiency rating of an oil filter for any given application should never be the only consideration. For example, an oil filter’s resistance to leaking under extreme pressures such as pressure spikes after cold engine starts, or as a result of severe engine vibrations is equally important, as is the durability and reliability of internal oil filter components like anti- drain back and pressure relief valves.

Moreover, this document published by Fram also cautions against the numbers game, which caution we will quote here verbatim, “…End-users should also be wary of numbers games – they can also be played with B ratios. B ratios higher than 75 indicate little additional improvement in filtering efficiency. Furthermore, the test procedure to develop the B ratio is valid only for B values up to 75. For B ratios of 75 and higher, there are not enough particles in downstream liquid samples to make counting them statistically significant."

Source: https://www.fram.com/media/wysiwyg/resources/consumer_tech_docs/fluidfilterrating.pdf'

As far as oil filters go, the above should equip us with the knowledge to educate our customers on the importance of using only high-quality filters that are fully warranted by Fram, but since modern engines also require high-quality air filters, let us move on to look at-

Unlike oil and fuel filters that are tested only until a specified pressure differential is established across the filter, air filters are tested according to the prescripts of the ISO5011 standard to the point where they are said to have reached the ends of their lives. Fram also follows this standard, and here is how it works-

Air is passed through a standard test filter in a test rig that allows for the continuous introduction of known quantities of standardized test dust that is representative of the types of dust and particulate matter an end user is likely to encounter under real-world driving conditions. The test equipment also contains an absolute filter downstream of the test filter to catch all particles that manage to bypass the test filter.

The test runs until the filter creates a restriction in the airflow through the test equipment that meets a predefined level, at which point the test filter reaches the end of its useful life. At this point, the accumulated dust on the test filter is collected and weighed, and compared to the total weight of the test dust that was introduced into the test equipment. The difference between the two values represents the test filter’s capacity.

Moreover, the dust that had collected on the absolute filter is also collected, weighed, and compared to the weight of the dust the test filter had captured. The difference between the two values is expressed as a percentage that represents the efficiency of the test filter, which begs this question-

Seeing that all major manufacturers of air filters test their products in the same way, there must be some aspects or features of Fram air filters that differentiate Fram air filters from competing brands. There are indeed such features and they include but are not limited to the following-

Specialised filter media

Fram air filters feature plant-based cellulose and synthetic media that are designed specifically for our local conditions. This means that all Fram air filters trap and contain dust particles that are big enough to potentially cause engine damage.

In this regard, it is worth remembering that dust particles that are smaller than the operating clearances in an engine will pass through these clearances without touching sides, (in a manner of speaking) while particles that are bigger than the engine's operating clearances will not be able to enter the free space between moving parts.

In practice, it is particles that are comparable in size to the operating clearances in an engine that cause the most damage to engine bearings and other surfaces, and it is particles in this range of diameters that Fram air filters trap and contain before they can enter the engine.

Moisture-resistant filter media

Since high humidity is a defining characteristic of the climate over much of Australia, the filter media in Fram air filters are designed to be resistant to moisture that can potentially destroy the filtering capabilities of other types of media. As a result, Fram air filters have useful service lives that largely correlate with air filter replacement intervals specified by major car manufacturers.

Of course, air filter replacement intervals should be adapted on vehicles that operate in extreme conditions, but be aware of the fact that an air filter’s condition cannot be assessed through a visual inspection of the filter. For instance, an air filter might appear to be clogged to the point of uselessness, but that same air filter might still have a significant portion of its useful life left, so use your best judgment when servicing air filters in extreme conditions.

Fram air filters do not leak

All Fram panel air filters feature seals made from high-density polyurethane foam to ensure a proper fit in the air filter housing/box to prevent unfiltered air from entering the engine. This, of course, assumes that there are no leaks elsewhere in the intake system.

Farm air filters do not affect or void new vehicle warranties

Since air filters play a critical role in efficient engine operation, Fram pays close attention to the details involved in manufacturing air filters that meet, and often exceed the stringent quality and operating standards set by car manufacturers and regulatory bodies.

As a result, fitting Fram air filters during scheduled service and maintenance procedures on our customer’s vehicles will not affect or void the warranties on their vehicles, which brings us to the topic of-

Although the importance of having a properly working A/C system in our climate cannot be overemphasised, the weak point in this proposition is often the cabin air filter. In many cases, vehicle owners use price as the main consideration when they replace the cabin air filters in their vehicles, or they do not replace the filter until the A/C system can no longer force cool air through a clogged filter.

Nonetheless, the point we are making is that cabin air filters are not created equal. Therefore, it is up to us as mechanics and technicians to educate our customers on the importance of using only high-quality, and fully warranted Fram cabin air filters to ensure that the A/C systems in their vehicles work as expected.

Some of the advantages of using Fram cabin air filters we might mention to our customers include the facts that Fram Fresh Breeze cabin filters remove up to 98 per cent of dust particles that are larger than 10 microns in diameter from the air entering the cabin and that these filters also prevent the windscreen from misting up, which is a major advantage from a safety perspective.

We might also mention that Fram Cabin air filters are available in two forms, these being-

Carbon activated filters

The activated carbon in Fram cabin air filters absorbs and neutralises many air-borne pollutants including carbon monoxide and nitrogen oxide both of which are serious health hazards, especially to the elderly, young children, and persons with compromised immune systems.

However, carbon cabin air filters need to be replaced at least once a year to maintain the air quality in a vehicle.

Particulate cabin air filters

Fram particulate cabin air filters use a fibrous filter medium that captures and contains solid particulate matter that range in size from about 0.3 microns to 10 microns and larger. Although these filters are very effective at keeping most solid particulate matter out of a vehicle’s cabin, they are not as effective in filtering out bacteria and other harmful microorganisms as activated carbon cabin air filters.

So while proper and effective air and oil filtration is crucially important, no vehicle can run efficiently with a clogged or poor-quality fuel filter, so let us look at-

If all Fram filters are equal in terms of their fitness for purpose, then Fram fuel filters and water separators are the first among equals because modern fuel injection equipment demand clean and uncontaminated fuel if the injection system is to work as expected.

In practice, Fram designs and engineers fuel filters that meet and often exceed the performance standards set by manufacturers of both diesel and petrol engines, which is no easy task, given our notoriously dirty fuel. Nonetheless, Fram fuel filters are designed to satisfy the demands of especially returnless fuel systems, since excessive backpressure in the fuel system starves the engine of fuel.

As a practical matter, price alone should never be the main or only consideration when we replace fuel filters on our customers’ vehicles. When we do replace a fuel filter, the guiding principle should always be whether (or not, as the case may be) the replacement filter can maintain the required fuel flow rate while effectively removing impurities from the fuel, at the same time.

In terms of their efficiency and fitness for purpose, Fram fuel filters tick all the right boxes, regardless of the application. Moreover, Fram supplies fuel filters in all common forms, including-

It is perhaps worth keeping in mind that the operating clearances in modern fuel injectors and injection pumps are on average only 3 to 5 microns wide. This means that solid particulate matter in this range of sizes can cause serious and sometimes fatal damage to injection equipment unless they are removed from the fuel by an effective Fram fuel filter, which leaves us with this-

We’ve made the point before, but it bears repeating: effective air and fluid filtration is crucially important to keep modern vehicles operating at peak efficiency. Thus, regardless of the vehicles our customers drive, Fram offers filtration solutions that meet the particular filtration needs and demands our customers might face at any given moment.

Such solutions might include a complete filter kit for a 4WD vehicle, an oil filter that is optimized for synthetic engine oil, a carbon-activated cabin air filter to prevent noxious smells and gases from entering a vehicle operating in dense city traffic, or perhaps an efficient and effective nylon inline fuel filter for a motorcycle or lawnmower.

We never know what air and fluid filtration problems we might see in our bays from day to day, but it helps to know that whatever the problem might be, using a Fram filtration product will almost always go a long way towards solving the problem.