When it comes to cabin air filters, do you always stick to the manufacturers’ replacement schedule, or do you sometimes not replace the filter because it still looks “OK”? More to the point though, is checking and/or replacing the cabin air filter always your point of departure when you diagnose A/C systems for poor performance issues? We could perhaps all benefit from rethinking our approach to cabin air filtration because while we all know that clogged cabin air filters impede airflow through the A/C system, cabin filters play a bigger role in our customers' health and well-being than we know.

Thus, in this article, we will take a closer look at cabin air filters in terms of how they work, and why neglecting this critically important service item could have serious implications for the health of our customers- given that the average Australian passenger vehicle covers a distance of about 12 600 km per year with much of that distance covered with A/C systems in operation. Let us start with-

According to anecdotal sources, the story goes that about 70 years ago, the chauffeur of an erstwhile CEO of the Freudenberg Filtration Company, which was based in Germany, had an extremely difficult time keeping his uniform, and especially his crisp white shirts, clean when driving his employer around the city of Weinheim, where the company’s headquarters were located.

This area of Germany was heavily industrialised at the time, and pollution control measures were not almost non-existent. Long story short, though; eventually the hapless chauffeur got tired of changing shirts after every trip, and hit on the idea of covering up the vehicle's air vents with pieces of non-woven fabric, which was one of the principal products his employer's company was producing at the time.

The strategy worked. The non-woven fabric was highly effective in preventing, dust, smoke, and other solid particulates from entering the vehicle; in fact, it was said to be so effective that the chauffeur no longer had to carry a suitcase full of spare shirts around with him just to get through his day.

This discovery did not go unnoticed by the chauffeur’s employer, but history is silent on whether (or not), the chauffeur was credited with inventing the first cabin air filtration system, which was dubbed the “Viledon Filter Mat”. Nonetheless, the fact is that various non-woven fabrics, including the original Viledon material, still form the foundation of modern cabin air filtration systems today, which brings us to-

Although Freudenberg is a global leader in developing air filtration solutions in a wide range of industries, which now includes automotive cabin air filtration, air conditioning was not as common on the vehicles of forty years ago as it is on modern vehicles.

Moreover, even as recently as the late 1980s, the effect of ambient pollution on people’s overall health was still poorly understood, and many automotive A/C systems of that time still operated with poorly constructed filters, and sometimes, with no filtration at all. Consider this: even though Freudenberg was the global leader in the development and manufacture of automotive cabin air filters in 1989, their total production output for that year was only about 35 000 filter elements.

By 1993, this had increased to about 3.6 million filters. However, not all of the increased output can be attributed to the notions that a), Freudenberg's filters were somehow "better" than the products of its competitors, or b), that improved cabin air filtration has known, and quantifiable positive effects on the overall health of people that spend long periods in vehicles.

In practice, the primary driver behind Freudenberg’s increased output of cabin air filters had more to do with increasing global consumer demand for creature comforts, including air conditioning, in a wider range of vehicles, including mid and entry-level models. This demand was further fuelled by competition among OEM manufacturers for market share, and by the early 2000s, it was becoming difficult to find even basic models without air conditioning.

Nevertheless, by the mid-2000s, it was becoming increasingly clear to public health authorities the world over that many health issues, and particularly respiratory issues, stem directly from exposure to pollutants derived not only from exhaust emissions, but also from the wearing down of friction material(s), tyres, and the decomposing of adhesives and constituents in plastics used in vehicle construction. It was also around this time that several studies performed by specialised research units found that the concentration(s) of these and other pollutants inside closed vehicles can be as much as six times higher than in the ambient atmosphere outside a vehicle.

These findings were not lost on the air filtration industry, and particularly not on the Freudenberg Company, who, recently stated via a senior filtration engineer that- “It was our [Freudenberg’s] mission to improve human health and well-being that inspired the change in focus from the engine to the people inside the vehicle."

This mission has largely been successful, but to say that Freudenberg was the only manufacturer that embarked on it would be inaccurate. The fact is that starting in the early 2000s, all major manufacturers of air filtration systems the world over began working with OEM vehicle manufacturers, regulatory bodies, public health institutes/authorities, research institutions, and even privately-run public health advocacy groups to develop and supply the most efficient cabin air filtration solutions that modern technology can devise.

The result of these collaborations is cabin air filters that do vastly more than filter out dust and prevent insects from entering the vehicle through the A/C system, so let us look at some of-

NOTE: It is not the intention of this article to a) promote the products of any filter manufacturer over the products of any other filter manufacturer, or b), to denigrate or diminish the properties of any product as compared to any other product. Therefore, what follows is a discussion of the most pertinent properties any high-quality cabin air filter must or should have to satisfy current regulatory requirements. Note though that regulatory standards typically define minimum requirements, but in practice, the OEM-equivalent products of most cabin filter manufacturers, including a range of products from this supplier, often exceed current minimum requirements by a significant margin.

Before we get to specifics, it is perhaps worth mentioning that not all customers need or want premium cabin air filters. Some customers are comfortable with middle-of-the-road filters in terms of both efficiency and cost, and to satisfy this demand, most manufacturers supply cabin air filters with varying efficiencies. However, there are too many variants and types of cabin air filter available today to mention or list all, or even most here, so be sure to review product specifications for specific applications.

Premium filters, on the other hand, all share largely the same properties and characteristics, so let us start by looking at-

Solid particle entrapment

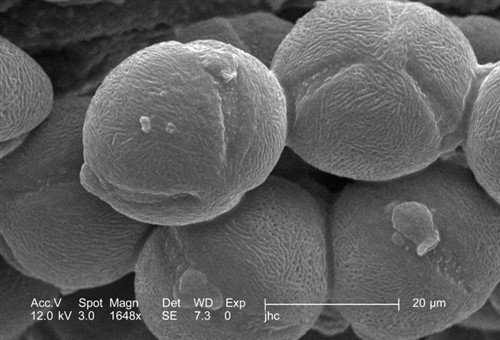

While most manufacturers supply a range of cabin filters that remove dust particles as small as 10 microns, most also supply filters that remove pollen grains, diesel soot particles, various fungus spores, moulds, and mildews that can be as small as 0.3 microns.

As a point of interest, the diameter of the virus that causes COVID-19 is between 0.06 micron and 0.14 micron (as measured by electron microscopes), which makes it smaller than some dust particles, but significantly bigger than the solid particular matter in cigarette smoke, diesel exhaust, and some mildew spores.

Therefore, an automotive cabin filter that can trap small mildew spores and diesel soot should also be able to capture at least some corona viruses. Although this writer has not been able to find specific studies that researched automotive cabin filters’ efficiency in trapping corona viruses, it is nevertheless encouraging to think that given their diameter, at least some corona viruses won’t make it through a premium cabin air filter.

Neutralising gases

These kinds of filters are commonly known as "combifilters" after their ability to not only trap solid particulate matter but also for how they neutralise several harmful gases, at the same time.

Most manufacturers supply combifilters for application in high-end applications, but some have now started producing these kinds of filters for general use in lesser vehicles, as well. As a practical matter, the mechanisms that neutralise or absorb harmful gasses like hydrocarbons, sulphur dioxide, nitrogen dioxide, ozone, and even toluene vary between manufacturers, but all premium filters are largely equally effective. Nitrogen dioxide, in particular, is a waste product of petrol combustion, and it is absorbed through the lungs; it can cause sudden heart failure and death if a vehicle’s occupants are exposed to it in high concentrations, or over prolonged periods.

Toluene, on the other hand, is a principal component of the adhesives that are used to stick down carpets and cloth upholstery in cars. Other sources include hydrocarbon vapours, shoe polish, paint thinners, and rubber compounds in tyres, from which it is released as tyres age or wear down. In terms of toxicity, toluene causes fatigue, loss of concentration, severe headaches, sleepiness, hallucinations, and too many other physical and central nervous system issues to list here, but sleepiness and loss of concentration might just explain some of the strange one-vehicle crashes we see almost every day.

We stated elsewhere that manufacturers use different methods to entrap and neutralise these gases. Some use activated charcoal that is either layered into the fabric of the filter, while others impregnate the filter medium with fine particles of activated charcoal. Other methods include the use of ordinary baking soda (bicarbonate of soda) in conjunction with activated charcoal to absorb sulphur dioxide, one of the gases cause that “rotten-egg” smell.

Neutralising allergens

Image source: Public Domain (https://pixnio.com/)

Millions of people worldwide suffer from severe allergic reactions to pollen such as the example shown above, and anybody who has had such a reaction will say that suffering an attack while driving a vehicle is a nightmare. Therefore, several manufacturers of cabin filters have now started using a substance called Polyphenol in the construction of their products.

Polyphenol is a natural anti-allergen that is found in grape seeds, and it works by chemically deactivating many kinds of pollen grains in a way that obviates the need for the human body to release antibodies to fight off the allergen. The itching eyes, nasal congestion, sneeze attacks, and other symptoms are the result of the body's reaction to the allergen (pollen in this case), so by impregnating the filer medium with polyphenol, pollen grains (and incidentally, dust mites) are deactivated before they can enter the vehicle through the A/C system.

Some manufacturers also apply an electrostatic charge to the cabin filter to improve the filter’s ability to “hold on to” entrapped particulate matter and allergens by as much as 150%.

Although the standards and test procedures to evaluate the efficiency of anti-allergenic cabin air filters are not available without very expensive subscriptions to official sources, several independent motoring organisations across the world have performed unofficial tests in recent years. Most tests involved running the A/C blower at medium or low speeds and most researchers have found that as a general rule of thumb, most cabin filters can remove about 90% of airborne solid particulates from the (re-circulated) air inside a vehicle in about 5 minutes, and about 99.5% of particulates in about 15 minutes, which brings us to-

Although the technology of cabin air filtration has come a very long way in the past few decades, the pressure by consumers on car manufacturers to provide even cleaner environments in their vehicles is now driving efforts to develop even more efficient filtration methods and technologies, some of which include the following-

Cluster ionisers

These devices are similar to ozone generators, in the sense that they generate ionised (electrically charged) hydrogen molecules to attract both organic and inorganic solid particulates. The different charges of the molecules and the particulates act like a sort of magnet that traps particles and deposits them onto a collector plate, which is not a part of the filter element.

Although this method does create/generate some ozone, which can potentially be harmful, ozone generation over eight hours of continuous operation of automotive ionisers typically amounts to only about 5 parts (of ozone) per billion, which is less than the background ozone saturation of ambient air.

Plasma-cutter ionisers

These devices use high-energy currents to create a high-temperature environment that strips hydrogen molecules from microorganisms to deactivate them. Essentially, the process dehydrates bacteria and other microorganisms, thereby sterilising the air flowing through the cabin filter. In typical designs, the ionising device deposits deactivated organisms onto the cabin filter, which then captures and contains them like any other type of particulate.

Air quality sensors

Air quality sensors are already in use in some Ford, GM, BMW, Volvo, and Toyota vehicles, their purpose being to a) detect potentially dangerous levels of carbon dioxide inside the vehicle, and b), to switch the A/C system from recirculation to fresh air automatically when CO2 levels reach a predefined threshold. Conversely, the sensors are designed to switch from fresh air to recirculation, in, for instance, traffic tunnels to prevent the high concentrations of harmful gases in the tunnel from entering the vehicle.

However, research is now underway to develop sensors that can detect other gases such as toluene, carbon monoxide, nitrogen oxide, and others to improve the air quality in vehicles even further, which leaves us with this-

We hope that this article has given you some new insights into the role cabin air filters play not only in the larger climate control systems in modern vehicles but also in how neglecting proper cabin air filter service and replacement procedures can potentially affect our customers' health and comfort.

Moreover, we are willing to bet good money that many, if not most of our customers are unaware of the many health benefits that switching to a premium cabin air filter entails. Therefore, now might be a good time to start educating customers on the importance of proper cabin air filtration- not only for the sake of their health and comfort but also for the increased business opportunities that come with increasing our customers' knowledge about cabin air filtration.