In several previous articles, we mentioned excessive oil consumption on new vehicles as a symptom of bad, poor, or expedient engine design, and in many, if not most cases of engines that are not designed as well as they might have been, these new engines consume prodigious amounts of oil from the moment they leave the showroom floor.

NOTE: Before we get to the specifics of oil consumption on rebuilt or reconditioned engines, it must be stated that it is not the intention of this article to suggest that all professional rebuilders turn out poor or substandard work when they rebuild or recondition car engines. Far from it; most professional engine rebuilders produce near factory-standard engines as a matter of course, so this article will focus on engines that have been rebuilt by non-professional or DIY engine rebuilders either to save some money or perhaps, as a favour to family and friends.

Therefore, in this article, we will focus on three of the most causes of excessive or increasing oil consumption on engines that have recently been rebuilt or reconditioned, many of which we see in our bays regularly, and on which the root causes of the problem can sometimes be extremely difficult to identify. In fact, in some cases that this writer had been involved with on behalf of insurers*, the root causes of excessive oil consumption in high-end vehicles and a few super cars were only identified by people wearing white coats using powerful microscopes and laser-based measuring equipment in specialized laboratories.

*While the details of these cases fall outside the scope of this article, investigations of increasing oil consumption on more mundane vehicles are usually less complicated. However, unless you are an expert engine rebuilder, it would be a mistake to think that the causes of increasing oil consumption on engines that were repaired on a DIY basis by non-professionals are always easy to identify or diagnose.

Much of the difficulty in diagnosing some oil consumption issues involves the fact that excessive or increased oil consumption problems do not follow a pattern. For instance, one rebuilt engine can begin to consume progressively larger volumes of oil almost immediately, while in others, oil consumption may increase slowly and steadily over several tens of thousands of kilometres of use. In yet others, increased oil consumption could begin slowly before increasing rapidly within only a few thousand kilometres of use to the point where the vehicle becomes undrivable due to excessive smoking and reduced engine performance.

Moreover, much of how the problem progresses involves how the vehicle is used, the quality of the parts used, as well as the skill level of the repairer, but since there is little point in simply listing more variables, let us start with the question of-

We covered this point as it relates to the engines in some new vehicles that are known to be oil guzzlers before, but if you missed the discussion in previous articles, here is the short version-

Car manufactures are at some pains to point out that there is no such thing as an engine that does not consume oil, and while this is true, it is also true that the methods car manufacturers use to measure oil consumption during a vehicles’ development phase are not easy to replicate consistently in the real world.

For instance, one common method car manufacturers use is to weigh the oil before and after an observation period, and the result of this test is then expressed as grams of oil used per kWh of work performed. (Italics added for emphasis)

There are other, equally abstruse methods, but the problem with all of them is that they are very difficult, if not always impossible to perform consistently in the vehicle repair industry, i.e., outside of laboratory settings and/or conditions.

Fortunately, though, there are more user-friendly ways not only to define excessive oil consumption, but also to a) make oil consumption tests repeatable, and b), to make oil consumption tests applicable to any vehicle regardless of its age, size, or variations in factors such as vehicle use, change in driving style, or distances travelled. Here is how this works, but bear in mind that this test only works, or becomes reliable if you can obtain accurate information from your customer-

So assuming that your customer is honest about the vehicles' fuel and oil consumption rates, you can use the number of litres of fuel the vehicle consumes in say, six months as a point of departure. Again, if your customer is honest about the number of litres of oil the vehicle consumes in the same period, you simply divide the oil consumption into the fuel consumption, which yields the vehicle's oil consumption as a percentage of fuel consumption.

While this percentage is different for every vehicle, the percentage value represents an objective result that takes into account all the variables that come with the daily use of that vehicle. Also, bear in mind that even though the percentage of oil consumption vs. fuel consumption may not change over short periods, or change very slowly over long(er) periods, this does not mean that the affected vehicle is not using excessive amounts of oil.

There is no reliable data available on how much oil any vehicle should consume at any point in its life, but the objective test should not be to determine whether (or not) the vehicle is consuming too much oil. The objective test should be to use the rate of oil consumption (as a percentage of fuel consumption) to track changes in oil consumption, which is often a feature of a reconditioned or rebuilt engine immediately after a rebuild.

Nonetheless, some rebuilt or reconditioned engines begin to consume excessive amounts of oil soon, if not immediately after a rebuild or major reconditioning, and diagnosing the root causes can sometimes be extremely challenging, especially if the rebuilding or reconditioning was not performed by a professional rebuilder. Nonetheless, one of the characteristics of excessive oil consumption on rebuilt engines is that the rate of oil consumption very rarely remains static.

Long experience in the engine repair business has taught this writer that excessive oil consumption rates typically increase as whatever it is that causes the problem becomes worse. Moreover, while this writer has no empirical proof of this, it seems that the rate of oil consumption on poorly rebuilt or badly reconditioned engines usually increases in direct proportion to non-professional engine rebuilders’ lack of skills, relevant experience, equipment, and technical knowledge.

In practice though, very few mechanics that work in general mechanical workshops ever get the opportunity to diagnose excessive oil consumption issues on rebuilt engines, mostly because the diagnostic process typically requires that the affected engine be disassembled, which can only be done after removing the engine from the vehicle. Even then, the root cause(s) of the problem might not be immediately apparent or visible.

Thus, if you are ever required to explain the possible cause(s) of excessive oil consumption on a rebuilt engine to a car owner, you may want to use the few most common issues we have found over many years as a guide. Let us start with-

Image source: https://university.fuelmotousa.com/wp-content/uploads/oilcontrolring.jpg

This image shows a 3-part oil control ring that is installed correctly; i.e., the two ends of the expander ring is touching, and not overlapping. This arrangement ensures that the two scraper rings are subjected to the correct tension to ensure efficient control of the oil film on the cylinder wall.

While it might strange, overlapping the two ends of expander rings is perhaps the most common mistake many non-professional engine rebuilders make when they install piston rings, even though an overlap in the expander ring often makes it very difficult, if not always almost impossible to fit the piston into the cylinder bore.

Nonetheless, even when the piston slides into the bore relatively easily with incorrectly fitted oil control rings, the result is a total lack of oil control since the two scraper rings are not tensioned correctly, and are therefore not in ideal contact with the cylinder wall. This causes-

In general, incorrectly fitted oil control rings will cause excessive oil consumption and concomitant smoking from the exhaust immediately after the engine is placed into service.

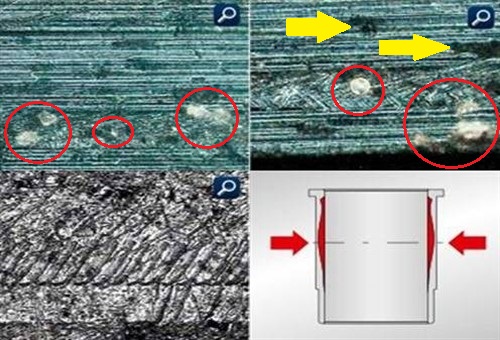

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

It is not entirely clear why many machine shops insist on blasting engines with highly abrasive materials like sand and glass in efforts to remove grime before working on them, but this composite image shows the results of this extremely harmful practice. Most non-professional rebuilders might think that sand-blasting an engine block is a good idea, but the reality is that it is virtually impossible to remove all the glass or sand from every nook and cranny in a modern engine block. Worse, though, high-pressure air forces the abrasive material into oil passages and other orifices, from where it is, in fact, impossible to remove the abrasive material.

Let us look at this composite image in some detail. The two top images show images (taken through a powerful microscope) of the wear surfaces of two different compression rings. The white spots circled in red are grains of extremely abrasive glass that had become embedded in the rings’ surface, which effectively turns the rings into a kind of grindstone that continually scrapes away at the cylinder wall. The two yellow arrows indicate spots (holes) on one of the rings' wear surface where some material had been torn out of the surface by large glass or sand particles.

The image in the bottom left is also of the wear surface of a compression ring, but in this case, the image was taken through a scanning electron microscope to reveal the score marks scratched into the rings’ wear surface by glass grains that had become entrapped between the cylinder wall and the rings’ wear surface. This type of damage is usually not visible to the naked eye; all that a casual visual inspection will show is the slightly dull appearance of the rings’ wear surface.

The image in the bottom right is an example of the type of barrel-shaped wear pattern (rendered in red) that is typical of the presence of large amounts of abrasive material like glass or sand in the engine.

As a practical matter, an engine in which the cylinders have become barrel-shaped is effectively destroyed, because glass or sand grains that have not become embedded in parts of the engine have been ground into exceedingly small grains that are circulating freely through the lubrication system. At this point, the oil and glass mixture is an excellent grinding compound, and it is present everywhere in the engine- it is in the camshaft(s) and crankshaft, it is present in the oil pump, and it is present between all moving parts.

Even worse, since shear forces wear much of the abrasive material down to between 3 and 5 microns in diameter relatively quickly, these particles are not filtered out of the oil because they are small enough to pass freely through a typical oil filter. Consider the composite image below-

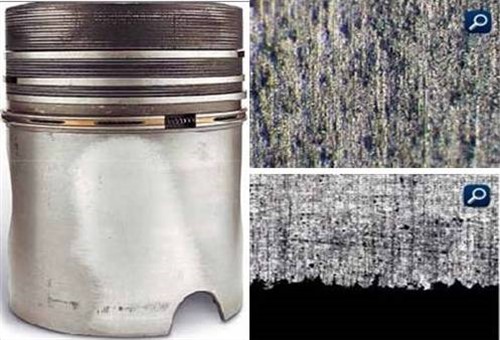

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

The piston shown in this composite image was taken from an engine that was ruined by the presence of finely-powdered glass in the oil. However, as shown here, the only apparent sign that something is not right is the area on the skirt that had taken on a somewhat shiny appearance.

To a casual observer, the shiny spot on the piston might appear perfectly smooth, and the oil in the engine will likely not even feel "gritty". However, the two smaller images to the right of the piston tell a different story. These images are views of the ring's wear surface as seen through a powerful microscope- the upper image shows how the powdered glass in the oil had gouged holes, furrows, and channels into the piston skirt’s surface. The lower image shows the bottom edge of the skirt, on which the ragged edge was formed by some of the material that had been gouged from the piston's surface. There is not much more to say about this kind of damage beyond stating that it is not possible to save or repair this engine because there is no reliable way to remove the finely powdered abrasive material from it.

Thus, the moral of this story is this- if you are going to be rebuilding an engine for a customer, we recommend that you do NOT allow the machine shop to use any form of blasting method with any abrasive material to “clean” the engine. Your customer will almost certainly never forgive you when his n engine has to be scrapped soon after the rebuild, which brings us to-

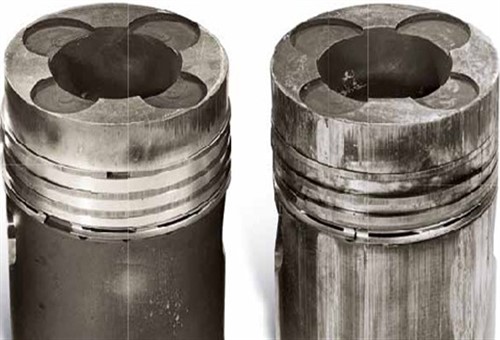

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

This image shows two views of the same part of the scuffed wear surface of a compression ring. The top view is slightly magnified by a strong magnifying glass, while the lower image was taken through a powerful microscope.

While ring scuffing can potentially occur on any rebuilt engine, ring scuffing is more common on rebuilt diesel engines that have not been run in correctly, because the rings in diesel engines are subjected to substantially higher loads and pressures than the rings in petrol engines. Therefore, the adverse effects of not following recommended running-in procedures are significantly greater in diesel engines than in petrol engines.

In this particular example, the diesel engine was operated at high speeds and loads immediately after a major rebuild, which prevented the rings from seating properly on the cylinder walls. Under these conditions, the high combustion pressure forced super-heated combustion gases past the unseated rings, which destroyed the lubricating oil film on the cylinder walls. Consider the image below-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

This comparative image of the two pistons was deliberately taken at an oblique angle to highlight the effects of ring scuffing. The piston on the left shows evidence of the early stages of ring scuffing, while the piston on the right shows the effects of ring scuffing at an advanced stage.

As stated above, blow-by gases destroy the lubricating film on the cylinder walls, which causes the rings to scuff against the cylinder walls. Additionally, the parts of the piston skirt that come into contact with areas of the cylinder wall where no lubrication is available also sustain damage as a result of boundary lubrication conditions. Moreover, the damage progression is rapid since the more the rings scuff against the cylinder walls, the further down the cylinder walls the blow-by gases destroy the oil film.

Even in cases where sufficient splash lubrication is available, the rough surfaces of the rings, cylinder walls, and piston skirts create severe boundary lubrication conditions that can generate sufficiently high temperatures for whatever lubrication is available to either carbonize or evaporate. This feature of ring scuffing explains why many diesel engines with severe ring scuffing do not emit large volumes of smoke from the exhaust; there is simply not enough oil passing into the combustion chambers past the rings to cause lots of smoke.

In fact, most rebuilt diesel engines that are suffering from ring scuffing seize as a result of insufficient cylinder wall lubrication long before the rings sustain enough damage to allow some splash oil to pass into the combustion chambers. Note though that although ring scuffing could also result from some abnormal combustion processes, it helps to bear in mind that ring scuffing is more likely to result from incorrect or improper surface finishing of cylinder walls than from abnormal combustion, which leaves us with this-

We hope that the information in this article has given you some new insights into at least some of the causes of excessive and/or increasing oil consumption in rebuilt engines. More to the point though, we hope that this article has illustrated the points that some causes of excessive oil consumption are not always immediately apparent or visible and that in some cases, you may need to use unconventional diagnostic aids like oblique lighting, magnifying glasses, and even microscopes.

Diagnosing some causes of excessive increasing oil consumption in rebuilt and reconditioned can sometimes be challenging. However, once you understand that what may sound like unlikely contributing factors can be (and often are) common causes of oil consumption issues, you will be in a better position to not only advise your customers on the many possible pitfalls and dangers of DIY engine repairs but also to make diagnoses without resorting to guesswork when DIY engine repairs go wrong.