Although it is true that Ford’s Powerstroke family of engines has a legion of fans, it would also be true to say that diesel technicians the world over are not overly fond of this series of engines, mainly because they are notoriously difficult to work on. Although the 6.7L engine was a huge improvement over its predecessor in this regard, the re-designed 6.7L engine was and is still plagued by a multitude of serious issues and problems that collectively, argue strongly against the notion that the 6.7L Powerstroke engine is reliable, durable, and economical to own and operate.

However, the focus of this article is not to debate the merits and/or demerits of Ford's Powerstroke engines. Instead, this article aims to provide both diesel and petrol technicians with practical advice on how to diagnose and resolve some of the most common issues they are likely to encounter specifically on Ford’s 6.7L Powerstroke engine. Take note however that to avoid misdiagnoses you must have access to Ford-compliant diagnostic equipment/software, as well as reliable and up-to-date service information, and in some cases, special Ford tools. Tools can be bought from official Ford sources; service information can be had via a subscription to third party vendors, while Ford-compliant diagnostic equipment can be obtained from https://www.sabtoolstore.com.au/diagnostic-scan-tools-and-accessories

Having said the above, let us start with a short description of the 6.7L engines’-

Instead of a lift pump in the fuel tank, 6.7L engines use a fuel conditioning module that is mounted on the engine to draw fuel from the tank with an electrically controlled pump. Apart from the pump, the fuel conditioning module also contains a water separator that removes moisture from the fuel before passing the fuel through a 10-micron secondary fuel filter. Separated water collects at the bottom of the fuel transfer pump, and the ECU triggers a WIF (Water in Fuel) warning when enough water has collected to be detected. Note that depending on the fuel temperature, fuel that is vented through the fuel pressure control valve is either returned to the fuel tank or directed to the inlet side of the fuel conditioning module to pass through the primary fuel filter.

It should be noted that the CP4 high-pressure fuel pumps on 6.7L engines are particularly susceptible to damage caused by insufficient supply pressure. Thus, to protect the pump, the low-pressure side contains a fuel delivery pressure switch, which is located in the fuel supply line upstream of the secondary fuel filter. This switch is normally closed, and only opens when the supply pressure reaches 53 psi; if the fuel supply pressure does not reach 53 psi and the pressure switch remains closed for longer than 60 seconds the ECU illuminates a “Low Fuel Pressure” warning. When this happens, the engine enters a “derate” condition, which is Ford-speak for a limp mode.

Note that 6.7L engines built from 2015 onwards are fitted with integrated fuel pressure and temperature sensors that supply input data to the ECU on fuel parameters such as fuel supply temperature and pressure. This is an improvement over pre-2015 engines in the sense that the ECU is better able to control and monitor the fuel supply to the high-pressure fuel pump, which brings us to-

WARNING: Take note of the fact that since this high-pressure fuel system generates pressures of up to 29 000 psi, using your hands or fingers to locate high-pressure fuel leaks could result in extremely serious personal injuries or even the loss of one or more fingers.

Nonetheless, fuel quality is extremely important for the efficient operation of this fuel system and seeing that the quality of Australian diesel fuel leaves much to be desired, 6.7L engines are particularly susceptible to issues that involve the fuel system in one way or another, typical issues being-

Hard-, or no start conditions

These kinds of issues can be tricky to diagnose on any Powerstroke engine, but as far as the 6.7L engine is concerned, the diagnostic procedure would follow the general pattern outlined below-

1) Since this system requires a minimum pressure of 5000 psi for the injectors to work, you need to monitor the fuel pressure with a scan tool while cranking the engine, but note that the actual fuel pressure must meet the desired fuel pressure, i.e., 5000 psi at all times. If this is the case but the engine will still not start, extract all fault codes (including pending codes) stored in all control modules, and resolve codes found in the order in which they were stored.

2) If the scan tool displays low fuel pressure during cranking, check the operation of the low-pressure system first by monitoring the status of the low-pressure fuel delivery switch. Note that the minimum allowable pressure is 52 psi, while normal pressure is between 53 and 73 psi.

3) If the low-pressure fuel system is OK, inspect both the primary and secondary fuel filters for evidence of clogging, or for evidence of gelled fuel, which is relatively common if the fuel contains high percentages of biodiesel. If filters are clogged, DTC codes P1291 and/or P1292 are likely present, both of which refer to short circuits in one or more injectors caused by contaminated fuel. Refer to TSB 11-10-10* if these codes are present, and follow the repair steps exactly to avoid further damage to the fuel system.

*Although this TSB refers specifically to fuel that is contaminated by DEF (Diesel Exhaust Fluid), other contaminants may also be at fault. Note that resolving these codes could involve replacing all eight fuel injectors.

4) If the fuel filters are clean, remove the (return) hose from the fuel pressure control valve located in the left-hand fuel rail, and block off the hose. Crank the engine; if fuel flows from the valve, the valve is defective and is the cause of the low fuel pressure.

5) Check for excessive return flows from the injectors by removing the return lines and plugging them. Crank the engine while monitoring the injector returns; some return flow is normal, but a return volume that exceeds 3 ml in 15 seconds while the engine is cranking or running at idle is excessive, and the cause of the low fuel pressure.

Image source: https://oregonfuelinjection.com/services-repair/diesel-diagnostics-repair/ford-diesel-diagnostics/

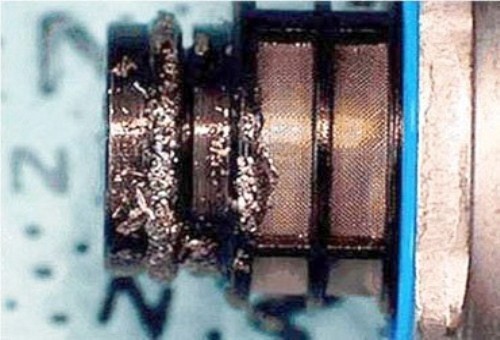

6) If injector return flows are normal, remove the high-pressure fuel regulator and inspect if for the presence of metal wear particles, as shown in the image above. Note that Ford does not specify a minimum allowable amount of wear particles- if any metal is present in or on the regulator, the prescribed repair calls for the replacement of the high-pressure fuel pump, fuel rails, all high-pressure fuel lines, all fuel injectors, as well as the pressure regulator and all fuel return lines.

While the few steps outlined above will generally allow most technicians to diagnose most fuel pressure related issues most of the time, the fuel injectors on 6.7L Powerstroke engines have their own reliability issues that are sometimes difficult to distinguish from other causes of some types of driveability issues. Nonetheless, long experience has shown that most drivability issues with 6.7L engines stem from faulty, defective, or malfunctioning fuel injectors, so let us start this section with a brief description of the-

Unlike most other diesel fuel injectors that are controlled with solenoids, the injectors on 6.7L engines are opened and closed with stacks of Piezo crystal wafers. When the Piezo wafers are energised they expand, which is the mechanism that lifts the injector needle off its seat.

In terms of specifics, however, each injector is supplied with high voltage supply and control circuits by the ECU, which uses dedicated capacitors to build and store the 250 volts at 20 Ampere that is required to open the injectors and to keep them open during injection events. To initiate an injection event, the ECU grounds the control circuit and supplies the injector with 250 volts through the supply circuit to open the injector, and to keep it open during the injection event. Closing the injector again is accomplished by removing power from the Piezo wafers, which causes them to contract, thereby closing the injector.

As a practical matter though, since the high voltages and pressures the injectors have to cope with generate a lot of heat, the injectors are cooled by a calibrated amount of fuel that flows through the body of each injector. If the injectors are in good condition this system works well, but if injectors are worn, defective, damaged, or contaminated, the amount of fuel that flows through them generally increases, which further affects the operation of the affected injectors. Moreover, and all other things being equal, the pressure in the injector return line has to be greater than 45 psi for the injectors to work at all, this pressure being controlled by an orifice in the injector return line. In practice then, the required 45-psi backpressure is generated by the relationship between the restriction caused by the orifice, and the internal leak rate (3 ml/15 seconds at idle or cranking) of the injectors.

As would be expected, the ECU has some ability to compensate for both normal wear of the injectors, and the loss of sensitivity of the Piezo wafers in the injectors. This is accomplished by a strategy Ford calls “Zero Fuel Calibration”, and its function is to detect, and compensate for deviations in individual injector performance from design specifications. Here is how it works-

During a fuel shut-off condition during deceleration, the ECU sets, or limits the fuel rail pressure to 4351 psi, but small, measured fuel injections are made through just one injector at a time. Since the small injections produce accelerations in the crankshaft’s rotational speed, the measured accelerations are compared to expected or desired accelerations. If the two values differ by more than 50%, the ECU initiates a further strategy that is designed to adapt the injectors’ duty cycle until the observed crankshaft speed matches the expected crankshaft speed, which brings us to-

It should be noted that while the issues listed below are most commonly caused by faulty, malfunctioning, or damaged fuel injectors, these issues could also be caused by other problems, some of which are also listed. Let us start with-

Misfires/Stalling

Misfires or random engine stalls can occur sporadically, or be permanent, depending on the exact nature of the problem. To confirm or eliminate one or more injectors as the cause, use a scan tool to disable all the injectors in turn. If an injector is at fault, the idling quality will change as each injector is disabled, but the idle quality will not change when the defective injector is disabled.

Note that other possible causes could include one or more of the following-

Severe engine knock

Isolate one cylinder at a time to identify the suspect injector, either with a scan tool or by blocking off the fuel supply to each injector in turn. Note that engine knock caused by contaminants entering and damaging injectors is relatively common.

White or blue smoke at idle

NOTE: It is recommended that DPF filters be disconnected from the exhaust system to eliminate a damaged or clogged DPF device as the cause of the smoke.

Isolate one cylinder at a time to identify the suspect injector. However, it should be noted that as with other issues that involve injectors, disabling an injector does not reduce the fuel pressure in the fuel rails. Therefore, it is always helpful to monitor cylinder power contribution rates as well since in some cases, injectors can leak during idling, but not at higher engine speeds.

The few pointers listed above should enable the average technician to diagnose most injector issues, but there are other serious issues on 6.7L Powerstroke engines that are worth taking note of, these being-

Oil dilution

The most common cause of oil dilution is fuel that leaks past the shaft seals on the high-pressure fuel pump. In severe cases, more than a litre of fuel can seep into the oil between oil changes, which makes it critically important to advise customers to check engine oil levels at least once a week, if not daily.

High-pressure fuel pump failure

The CP4.2 pumps on some 6.7L engines are not nearly as durable as the CP3 pumps that are fitted to other Powerstroke engines. As a result, when a CP4.2 pump fails as the result of contaminated fuel or clogged fuel filters, the failure is almost invariably catastrophic in the sense that not only the pump is destroyed, but also that the damaged pump almost always distributes metal wear particles throughout the high-pressure fuel system and into injectors- which destroys the injectors, as well.

DPF failure

Any fuel system failure will cause the DPF to fail prematurely. Therefore, if the DPF fails prematurely, regularly or repeatedly, investigate the fuel system first before investigating other causes such as damaged turbochargers, EGR systems, or mechanical issues with the engine itself. Note that replacing the DPF before addressing or investigating all possible underlying causes of repeated DPF failures will only result in the premature failure of the replacement DPF, which leaves us with this-

Since fuel system failures on the 6.7L Powerstroke engine are always very expensive to repair, it is incumbent upon us to be sure of our diagnoses when we prepare quotes and estimates on repair costs. A misdiagnosis will not only hurt out customer- it will definitely hurt us as much, if not more when we have to pay for say, a high-pressure fuel pump when we thought all that needed replacing was a fuel filter.

To be sure this does not happen to you, spend a bit of time reading through the relevant service information before you do anything on any Powerstroke engine. Chances are that if you don’t you’ll end up doing something wrong, and that will almost certainly cost both you and your customer a ton of money.