NGK has over 80 years of ignition expertise and remains at the forefront of technological innovation. As ignition specialists, NGK partners with OE engine manufacturers to ensure all NGK Glow Plugs meet exacting engine specific requirements. To meet strict quality benchmarks every single NGK Glow Plug is tested before being packaged and made available for sale.

Manufactured with state of the art techniques, all NGK Glow Plugs ensure high quality and reliability in order to:

Maintain optimum starting capabilities

Offer an excellent post-glow function

Promote clean combustion

Lower toxic emissions

Every glow plug has its own unique characteristics specific to its application, and although such key elements cannot be seen from visual inspection, usage of a generic glow plug can result in a compromise of engine performance.

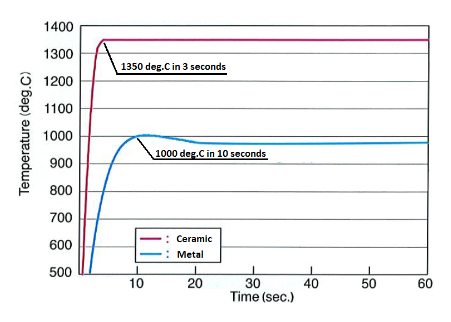

Glow plugs are designed to reach their saturation temperature after a specific period of time, at a given voltage application and this temperature must be maintained for a specific period of time to provide stable combustion conditions. Diesel engine performance and toxic emissions can only be improved if the glow plug matches or exceeds the engine manufacturer’s specification.

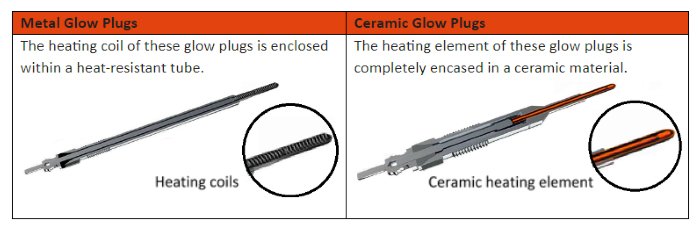

NGK glow plugs can be broadly classified into two groups which are outlined below:

Ceramic glow plugs are engineered to perform under the most extreme conditions. Compared to a metal glow plug they have a more robust heating element which is made from a special high melting point material. This is encased in Ceramic (Silicon Nitride) which has extremely good thermal conductivity properties and can withstand very rapid heating times over extended service periods.

The combination of heating element and ceramic coating allows ceramic glow plugs to reach higher temperatures than metal type glow plugs, enabling the engine to reach operating temperature particularly quickly. Secondly, due to the robust nature of the heating element and ceramic materials, post-glow times of up to ten minutes can be employed.

Ceramic glow plugs are also more compact in design, catering to the little free space in today’s engines.

Metal glow plugs and Ceramic glow plugs are NOT interchangeable.

The graph below shows the heating characteristics for a typical Metal and Ceramic glow plug.

An increased number of vehicle manufacturers have chosen NGK Ceramic Glow Plugs instead of the metal type for their production line, including Audi, BMW, Citroën, Ford, Land Rover, Mazda, Mercedes-Benz, Mitsubishi, Peugeot, Renault and Volkswagen. One reason for this is NGK’s superior competence in the field of technical ceramics. This enables research and development of new glow plugs for increasingly strict emissions targets and reduced engine sizes. It is this connection that drives NGK’s engineers in Japan to constantly research new materials, designs and production processes which lead to technological advancements like the NHTC Glow Plug and further innovations to come in the future.

Choose the Glow Plug specifically engineered for your vehicle’s engine, choose NGK!