There was a time when doing some relatively simple relearning procedures or adaptations was all that was needed after automatic transmission repairs or replacements to get a vehicle on the road again. Sadly, though, those days are long gone; some Chrysler and GM gearboxes have required resetting of clutch volume indexes and transmission adaptive pressures since the early 1990s, while on some other contemporary makes and models, a complete reprogramming of the transmission control module was required to make the repaired/replacement transmission work correctly.

If you are not a specialist transmission technician, you may or may not be aware of the special steps you now need to take to commission a repaired or used modern transmission, so in this article, we will focus on what you need to do to commission a modern Ford transmission successfully, starting with this question-

There are two reasons for this. The first is that since transmission-commissioning requirements vary hugely between manufacturers and transmission models/types, this article cannot provide sufficient information to cover all applications and/or situations, and the second reason is one particular Ford transmission, the DPS-6 (aka the PowerShift transmission), can often be particularly difficult and challenging to commission successfully.

Although the DPS-6 transmission is no longer used in new vehicles in the North American market, it is still widely used in several new Ford products in other markets. For instance, the DPS-6 transmission is still used in Ford Fiesta, Focus, Transit, and C-MAX applications (and others), meaning that you are more likely to encounter issues on DPS-6 transmissions than on any other transmission(s) currently in use on Ford applications.

Nonetheless, before we get to the specifics of the DPS-6 transmission, let us consider the recent case of a Ford Focus with serious shifting issues that a non-Ford dealership recently referred to this writer. Note though that while this case study involves a Ford Focus model, the general diagnostic and repair steps outlined here apply to all Ford models equipped with DPS-6 transmissions, so let us start with-

We need not discuss the reasons why this vehicle was referred to this writer. Suffice to say that a) the transmission was replaced by a dealership that deals with Japanese vehicles, and b), that when it arrived at this writer's establishment the transmission either delayed or missed shift points and when it did shift, all shifts (up and down) were unpredictable and harsh, and even violently so at moderate to high engine speeds.

The technician who had performed the replacement and subsequently delivered the Focus to us asked that we perform a visual inspection to verify that he "had not missed anything", and could we also please reprogram the TCM (Transmission Control Module) while he waited since his employer was somewhat less than pleased with the outcome of the transmission replacement?

The inspection showed that “nothing (obvious) was missed”, but the hapless tech did mention the fact that his employer, and not the client, had sourced the remanufactured transmission from a trusted supplier. The tech also stated that while this particular supplier had supplied them with many remanufactured non-Ford transmissions before, this was the first time they experienced any kind of trouble with a transmission this remanufacturer had supplied to them.

In the interest of full disclosure, it must be stated that we would not have accepted this job if a) this writer had not seen this problem before on other Ford products equipped with DPS-6 transmissions, b), the workshop supervisor was not an experienced ex-Ford dealership tech, and C) if we did not recently invest in an IDS (Ford-specific) scan tool. “C” happened on the workshop supervisor’s insistence when he first joined the writer’s staff.

There is much more to say about the background of this case but for the sake of brevity, let us concentrate on the specifics of the problem, starting with-

The diagnostics

Given the excellent reputation of the transmission remanufacturer, this writer agreed with his workshop supervisor that the real issue was far more likely to involve a programming issue than a mistake or oversight on the part of the remanufacturer. Therefore, we performed a full diagnostic scan with the IDS scan tool, which revealed the fact that the ID of the valve body (in the current transmission) did not match the valve body ID that was originally assigned to the vehicle's VIN. This type of problem cannot be resolved with a simple reprogramming of a Ford TCM with global software; it can only be resolved by reprogramming the TCM with transmission-specific software, about which official Ford service information has the following to say-

“If a new solenoid body is installed, the solenoid body strategy and solenoid body ID will need to be updated. Refer to Solenoid Body Strategy.”

It should be noted though that while many high-end generic scan tools will allow you to view current valve body ID information on Ford applications, no generic scan tool will allow you to edit, change, delete, or update any data relating to valve body ID and/or valve body strategies on any modern Ford application.

Nonetheless, while the required information can usually be found on a rather durable label attached to the transmission casing this was a rebuilt unit, and the label had been destroyed during the rebuilding process. However, Ford service information also states that the relevant/required data can be found printed on the valve body, such as shown in the image below-

Image source: https://www.searchautoparts.com/sites/default/files/images/Fig%201_6.jpg

Accessing this information requires removal of the transmission sump, but note that in some cases, there may be additional required data that might be in a different location in the transmission. Armed with this information, the TCM was updated (after connecting a clean power supply to the vehicle’s electrical system), the sump was replaced, and the transmission was refilled with the required fluid.

The subsequent test drive verified that the transmission’s shifting issues had been resolved successfully, and while all of the above sounds easy enough to do, there is nevertheless a moral to this story, and it is this-

Repairing, replacing, or servicing modern Ford transmissions require Ford-specific scan tools, and access to OEM service information and software, none of which may be available to most independent workshops and technicians. In this particular instance though, this writer could not have performed the repair had it not been for a serendipitous set of circumstances that included, among other things, access to Ford service information via the workshop supervisors’ rather expensive subscription to Ford resources, the availability of a Ford-specific scan tool, and the presence of an experienced Ford-trained technician to affect the repair.

This case is also a cautionary tale, in the sense that it does not matter how many times you have seen a particular issue on a modern Ford transmission before. The only thing that matters is that unless you have access to the tools, service information, and software required to update the valve body ID and/or strategies to complete a Ford transmission replacement or repair, you cannot, and should not attempt the repair.

In these cases, the wiser option is to refer the vehicle to a dealership, or to a specialist aftermarket repairer who does have access to the required information and tools. Both your customer and your employer will thank you later, which brings us to the-

Image source: https://www.focusfanatics.com/threads/latest-dct-software-update.600801/page-3#lg=thread-600801&slide=0

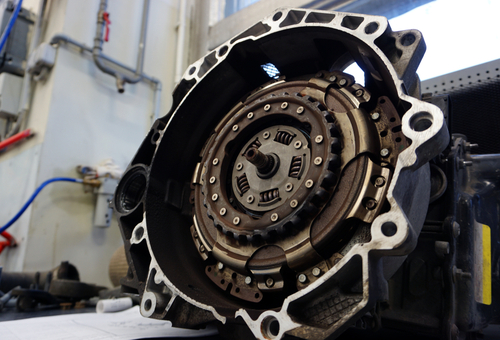

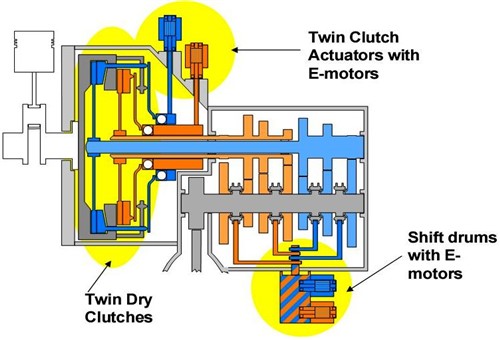

The image above shows a much-simplified schematic drawing of the internals of the Ford DPS-6 transmission, and while much had been written about the inherent unreliability of this transmission, the fact is that this transmission’s mechanicals are not only very robust- they are also very reliable. So what is the problem with this transmission, you may ask? You may well ask, but let’s look at how this transmission works, first.

As a practical matter, this transmission is a simple manual transmission in which gear changes are accomplished by gear selectors that decouple one set of gears before engaging another set of gears- just like in any other manual transmission. However, there are some noteworthy differences between how this transmission and conventional manual transmissions are controlled, and it is in these details that the proverbial devil lives.

For instance, this transmission runs off two dry-plate clutches that are connected to the transmission internals with two input shafts, one rotating inside the other to allow for independent rotation. The two clutches are controlled independently of each other by two three-phase motors much like the clutch actuators on most DSG transmissions, while gearshifts are managed by two more three-phase motors that control the movement of the gear selectors to select between the six available gear ratios.

Essentially, the DPS- 6 transmission is a fully automated manual transmission that is controlled by a dedicated Transmission Control Module. However, while the idea behind this design is good, the various calibration parameters of the many different moving parts need to be maintained within very narrow margins or ranges for the TCM to exercise or maintain effective control over the transmission as a whole, which begs this question-

Long experience with these transmissions has taught this writer three things. The first is that unless the transmission's control software is corrupted or damaged in any way, the mechanicals of most DPS-6 transmissions will often outlast the vehicles they are fitted to. The second thing is that unless both clutches are replaced as a set (regardless of their condition) whenever a DPS-6 transmission is removed from, and reinstalled into a vehicle the transmission will not work correctly, and the third is many DPS-6 transmissions are replaced unnecessarily because of clutch calibration issues. Let us take a closer look at each of these issues, starting with-

Software issues

Image source:Ford Motor Company (Service Information)

The above image of a DPS-6 transmission shows the label that indicates the software version that applies to this particular transmission. We need not delve into all possible conditions and/or circumstances that could potentially corrupt or damage the TCM's software here, beyond saying that shifting or clutch control issues are as likely to be the result of outdated or corrupted software as they are likely to be the result of an inherent, and seemingly irresolvable design flaws in the clutch control system.

Typical symptoms include, but are not limited to severe clutch slippage, clutch shuddering, delayed or no clutch activation, failure to select any gear or failure to select only some gears. While according to official Ford sources the standard remedy for software issues is either reprogramming or updating the TCM, the problem is that a) the required software and relevant service information is only available from official Ford sources, and b), that the procedure can only be performed with an IDS (Ford-specific) scan tool. You might be able to view transmission PID's with some high-end generic scan tools, but it has been this writer's experience that only an IDS scan tool will allow you to change and/or update a modern Ford’s TCM.

Clutch calibration issues

Typical symptoms are largely the same as above, but it should be noted that clutch calibration and control issues are the biggest single cause of customer complaints about this transmission. However, although Ford had issued more than 20 TSB's over the life of the DPS-6 transmission in efforts to resolve the problem, clutch calibration and control issues remain unresolved.

While replacement of both clutches sometimes seems to resolve the clutch shudder problem, this is not a guaranteed remedy in all cases, and even when it does resolve the issue, the problem often recurs a few thousand kilometres later. Therefore, and as a purely practical matter, there is very little the average independent workshop can do to resolve clutch issues on these transmissions, and especially so if the workshop does not have access to OEM-level scan tools OEM service information.

Unnecessary replacement

Unless a DPS-6 transmission suffers mechanical failures and/or malfunctions, which happens only rarely, there is little point in replacing it. For one thing, replacing the transmission will not resolve clutch control issues, and besides, if you do not have access to a suitable scan tool and OEM service information, you could not get the replacement transmission to work even halfway correctly, anyway.

Apart from the example cited at the beginning of this article, this writer has often been the third, and even fourth port of call for customers who cannot get the clutch issues on their DPS-6 transmissions resolved. While reprogramming and/or updating the TCM sometimes resolves the issue, albeit temporarily, it more often does not fix the problem (even temporarily), which brings us to this-

The only way to approach customers’ concerns with DPS-6 transmissions is with a great deal of circumspection and caution. We all want to do the right thing by our customers, but in the case of DPS-6 transmissions, the right thing should always start by researching the problem, and then deciding what you can, and cannot, do to resolve the problem before accepting the job.

At the risk of putting too fine a point on it, having access to the correct tools and service information is a prerequisite for performing service and repairs on, or replacements of, DPS-6 transmissions. In practice, this means that more often than not, doing the right by your customer is either refusing the job, or referring the vehicle to a dealership or specialist aftermarket repairer.