The notion that a petrol-based air/fuel mixture can be combusted by means of compression in a petrol engine is not new, and several theoretical engine designs exist in which it might be possible. However, turning a theoretical design into a working prototype engine that actually uses compression to ignite a petrol-based air/fuel mixture requires some serious out-of-the-box thinking, but it appears that Mazda has done just that.

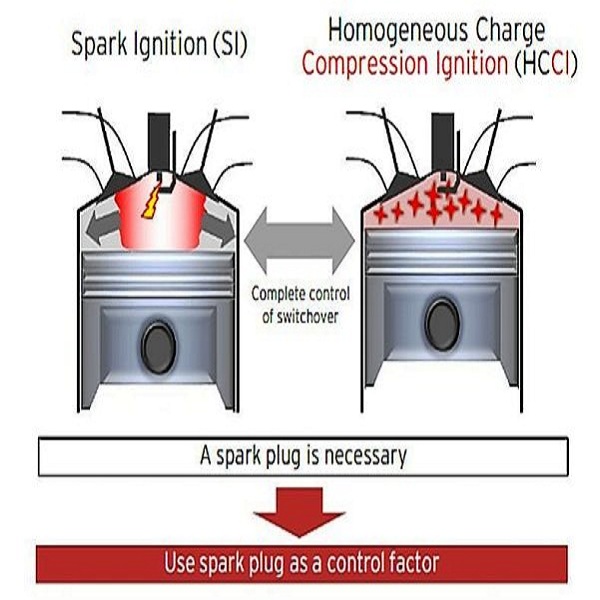

Following on the successful development of their Skyactiv-G and Skyactiv-D engines that use extreme compression ratios and ultra-lean fuel mixtures to extract more power from less fuel, Mazda has announced the successful development of their Skyactiv-X petrol engine that uses compression to ignite the air/fuel mixture, albeit with the assistance of a spark and some very complex software. In this article, we will briefly explain HCCI technology and the advantages it brings in terms of fuel economy and power delivery, starting with this question-

The acronym “HCCI” stands for Homogenous Charge Compression Ignition and it refers to the manner in which combustion of the air/fuel mixture in the Skyactiv-X engine is accomplished. In simple terms, the Skyactiv-X 2.0L four-cylinder engine uses a compression ratio of 16:1 to ignite an air/fuel mixture that can be as lean Lambda 2.5. In translation, this means that this engine can run on a fuel mixture that is twice as lean as the 14.7:1 (stoichiometric) mixture the normal spark-ignited petrol combustion process requires to burn all of the fuel using all of the available air in the mixture.

Even though HCCI technology has been shown to work, it must be understood that the combustion process and the way it is controlled differs significantly from the way the process works in a diesel engine. In a diesel engine, the heat derived from compression is the only mechanism that causes the air/fuel mixture to ignite at multiple points in the combustion chamber, but in the Skyactiv-X engine, the process of combustion follows a different route to ignite the air/fuel mixture at multiple points. Here is what happens-

Even though the compression ratio of 16:1 in the Skyactiv-X engine is very high, it is not high enough to initiate combustion of the air/fuel mixture, and a spark is still required to initiate combustion under most operating conditions. However, since the air/fuel mixture is twice as lean as a “normal” stoichiometric mixture, the fuel mist within the mixture is spread out so thinly that if the process of combustion depended on the spark alone, the detonation flame will propagate unevenly, and might even fizzle out altogether.

Therefore, the purpose of the high compression ratio is to heat the overall air/fuel mixture adiabatically to just below the point where it might combust with the heat of being compressed. Thus, when the spark is delivered, the initial detonation serves as the mechanism that supplies heat to superheat the excess air in the cylinder, which then exerts a downward force on the piston as it expands very rapidly. The result is that a greater downward force can be generated on the piston than is possible to do with a normal combustion process, even in the most efficient “normal” engines. It is perhaps worth noting that even though the initial compression temperature is somewhat higher than on a similar, conventional engine, the actual HCCI combustion temperature is significantly lower than on a similar conventional engine.

The process described above was somewhat simplified for the sake of clarity, and while it might seem straightforward enough, the actual details of the technology is somewhat more complex. Making the Skyactiv-X engine start and run reliably required that several major engineering challenges be resolved, some of which are described below-

Excess air supply

This was probably the easiest problem to solve, and in this case, Mazda engineers developed a small supercharger to supply the excess air. It must be noted however that the primary purpose of this device is not to supply compressed air to increase power, as a similar device would do on a normal engine. The sole purpose of the supercharger is to supply excess intake air in order to bring the air/fuel mixture down to Lambda 2.5.

Regulating ignition timing

As we know, the reason why the ignition timing on normal engines is as far advanced as it is, is to give the combustion flame sufficient time to propagate to the point where the combustion pressure peak is reached when the piston is at, or just after TDC.

However, with HCCI ignition, the combustion process is vastly faster, which means that ignition must take place when the piston is at DTC, or ideally on this particular engine, at 4 degrees after TDC. Moreover, since the combustion pressure is also significantly greater than on normal engines, any pre-ignition while the piston is on its upward stroke must be avoided to prevent damage to the piston, connecting rod, and other rotating components.

To avoid this possibility, the designers of the Skyactiv-X engine hit on the idea of splitting the fuel injection event into two discrete events. The first is a partial injection while the piston is moving downward on the intake stroke, while the main injection event takes place on the upward compression stroke. In practice, the minor injection ensures that the air/fuel mixture does not ignite prematurely, while the second injection event, which is completed just before the piston reaches TDC, further reduces the possibility that pre-ignition might occur.

However, under some conditions such as high ambient temperatures, some pre-ignition might still occur. To eliminate this problem, the designers of the engine have developed a system that retards the ignition timing, but in degrees after TDC to delay the delivery of the ignition spark.

Ensuring complete combustion under all conditions

As we know, combustion is less efficient at low ambient temperatures than it is at higher temperatures, which presented the Mazda engineers with a particularly thorny problem. Since the air/fuel mixture is so lean, initiating combustion in cold conditions required that the ignition and fuel delivery systems be capable of making suitable adjustments to compensate for changes in the density of the intake air, since density is a function of temperature.

However, since the ECU needs to “know” what current conditions are before it can make suitable adjustments to ignition and/or fuel delivery strategies, Mazda engineers developed and fitted pressure sensors to each cylinder, whose purpose it is to communicate the conditions in each cylinder to the ECU directly. The advantages of this are twofold; the first being that communication is faster and the second being that the ECU can adapt ignition timing and fuel delivery strategies individually for each cylinder to allow for slight variations in compression pressure that might develop over time due to uneven wear of valves, piston rings, etc.

Controlling the spark

While HCCI combustion can work without the need for a spark, the range of operating conditions (engine speed/load) under which it can do is very narrow. Typically, pure HCCI ignition would only be possible during high speed, wide-open-throttle cruising conditions, although it might become possible under less taxing conditions in future iterations of the technology.

Nonetheless, since an ignition spark is required most of the time, Mazda engineers have developed a system known as SPCCI (Spark-Controlled Compression Ignition) that makes it possible for the ECU to switch between the two modes of ignition seamlessly. Although no technical information about the SPCCI system is available, it appears that the system makes it possible for spark-assisted compression ignition to take place across the entire combustion range for this particular engine.

Controlling fuel atomisation

Since the air/fuel mixture is so lean on the Skyactiv-X engine, it is vitally important firstly that the fuel is properly atomised, and secondly, that the fuel is mixed uniformly through the air component of the mixture.

Again, no technical information is available, but according to official sources, the engine uses an ultra-high pressure fuel injection system that injects fuel through multiple-orifice injectors at pressures that approach those of modern direct-injection diesel injection systems. Moreover, the intake air is introduced with the aid of highly complex intake manifold runners to ensure that sufficient swirl is established so that the air and fuel is mixed uniformly.

Nonetheless, the piston crowns, combustion chambers, and inlet ports are designed so that a higher concentration of fuel is present around the spark plug than at any other point in the cylinder to ensure that the combustion process is initiated reliably. Moreover, since the compression pressure is very high and the bulk of the fuel is distributed evenly throughout the rest of the combustion chamber all the fuel ignites at the same time, as opposed to the air/fuel mixture igniting at one point, and then propagating outwards from that point as happens in a conventional engine.

According to official sources, the advantages of this technology are many and varied, some of which include-

Greatly improved fuel economy

According to official sources, the 2.0L Skyactiv-X prototype has achieved fuel savings of 20% over the Skyactiv-G engine, which is already vastly more fuel-efficient than conventional 2.0L Mazda engines. To put this into context, consider that the Skyactiv-X engine is up to 40% more fuel-efficient than the MZR engine that was released in 2008, which is comparable to the fuel efficiency of the Skyactiv-D diesel engine. Moreover, these fuel savings were realised under light engine load conditions, which dispels the notion that engines with large displacements are synonymous with poor fuel economy in city driving conditions- at least as far as HCCI technology is concerned.

Greatly improved throttle response and power delivery

Also according to official sources, the Skyactiv-X 2.0L engine delivers at least 10% more torque than the Skyactiv-G engine overall, but up to 30% more torque at certain (unspecified) engine speeds. Moreover, since the throttle plate on the Skyactiv-X engine is almost fully open during much of the engine’s operating range, throttle response is similar to that of high-end diesel engines-, which incidentally, are also not throttled.

It must be noted though that the Skyactiv-X HCCI-equipped engine also uses a high-tech, multi-stage exhaust manifold that is said to be extremely effective in extracting exhaust gas from the engine, as well as variable valve timing that uses electronically controlled stepper motors as actuators. Both of these factors are certain to contribute to throttle response and power delivery, so running with an open throttle most of the time cannot take all the credit for this engines’ claimed performance.

Reduced emissions?

Based on available knowledge, it is not certain to what extent HCCI technology has reduced the Skyactiv-X engines’ total emissions, if at all. However, since the engine is also fitted with an EGR system, it is reasonable to assume that HCCI technology alone cannot reduce emissions to the levels required by current emissions regulations.

While we know that HCCI technology works on a prototype engine, from the car repair industry’s perspective many questions remain unanswered, and especially questions about reliability.

For instance, as experienced technicians, we know that to prevent compression blow-by the piston rings have to form an almost gas tight seal against the cylinder walls. However, we also know that existing piston ring designs and configurations will not contain pressures that come with a 16:1 compression ratio.

Nonetheless, whatever the piston rings look like on the Skyactiv-X engine, they will have to work with cylinder walls that are perfectly circular, perfectly parallel, and presumably, almost perfectly smooth. However, we know that cylinder walls cannot be perfectly smooth- if they were, they could not accommodate an oil film to lubricate the piston rings.

What is certain however is that the high compression ratio on HCCI-equipped engines will place extreme demands on piston rings, which makes it more than likely that the cylinder walls on these engines will have high-tech coatings on them to assist with both gas sealing and lubrication. In addition, it is not at all certain that bearing shells as we know them will be able to withstand the rigours of a 16:1 compression ratio over extended periods, even with the high-tech synthetic engine oils that are available today.

A viable alternative to conventional bearing shells would be to use roller bearings on all crankshaft journals as well as on the connecting rod small ends, but until production versions of the Skyactiv-X HCCI become available, we will just to wait and see how the Mazda engineers tackled these issues.