It is said that necessity is the mother of invention and in recent times, one such necessary invention has been downsized petrol engines fitted with turbochargers and direct fuel injection systems. In this case, necessity stemmed from the need to meet the demands of the current Euro 6 emissions regulations and (theoretically), the more stringent demands of the Euro 7 emissions regulations that will come into effect in 2025.

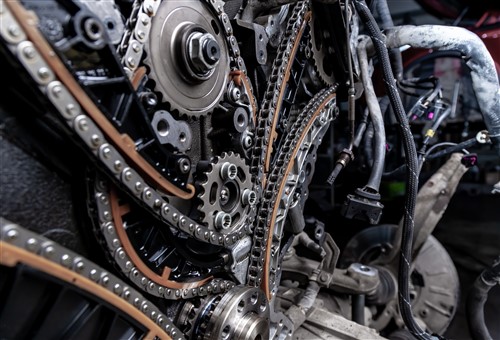

However, unlike serendipitous inventions, necessary inventions often come with unintended or undesirable consequences, which, in the case of downsized petrol engines, is a phenomenon known as low-speed pre-ignition that can cause fatal engine damage during low engine speed/high engine load operating conditions. In addition, low-speed pre-ignition is also implicated in increased engine wear rates, with timing chains and chain guides often failing prematurely because of soot -soot-contaminated engine oil. Thus, in this article, we will discuss the role of low-speed pre-ignition in premature timing chain failures in small-displacement direct injection engines, but before we get to specifics, we need to explain the differences between the terms low-speed pre-ignition and detonation, which are often incorrectly used interchangeably. Let us start with this question-

In an engine that is running normally, the detonation flame starts at the spark plug and propagates outwards at a constant rate, which produces a steady downward force on the pistons until they reach a position of about 80 or so degrees ATDC. Under these conditions, the engine produces predictable amounts of power at any given engine speed and load.

However, the presence of artificial hotspots in the engine, such as glowing carbon deposits on piston crowns or in the combustion chambers, or overheated spark plug electrodes can sometimes chaotically ignite the air/fuel mixture after the ignition spark has been delivered. This disrupts the smooth propagation of the combustion flame, which in turn, causes poor or incomplete combustion of the air/fuel mixture. In addition, poor combustion also causes an increase in the buildup of carbon deposits on piston crowns and in combustion chambers, thus increasing the likelihood of detonation conditions occurring under some operating conditions.

As a practical matter, detonation conditions cause sharp but chaotic pressure spikes in the combustion pressure, and although such pressure spikes can sometimes damage the engine in various ways, it is relatively rare for detonation conditions to cause serious engine damage, which brings us to the topic of-

Although detonation can affect almost any petrol engine under some operating conditions, the phenomenon of low-speed pre-ignition is largely confined to small displacement petrol engines fitted with forced induction and direct fuel injection systems. Moreover, unlike detonation conditions, low-speed pre-ignition can (and does) cause sudden and unexpected engine damage that is fatal more often than not.

In practice, low-speed pre-ignition typically occurs during low engine speeds when the engine experiences high-load conditions, and typical forms of engine damage include broken pistons, piston ring land fractures, bent or broken connecting rods, deformed crankshaft bearings, and in extreme cases, even crankshaft failures.

However, the exact causes of low-speed pre-ignition remain elusive, despite several decades' worth of research by dozens of research institutions and car manufacturers into the phenomenon. What is known though, is that a) low-speed pre-ignition is extremely common in small displacement engines with forced induction and b) low-speed pre-ignition always occurs before the ignition spark is delivered.

Moreover, advanced equipment has shown that low-speed pre-ignition can occur in the absence of localised hot spots in the cylinders, so exactly why the air/fuel mixture ignites spontaneously in several spots during injection events remains largely unknown. Although some researchers think that low-speed pre-ignition might occur as the result of the high compression ratios in small displacement direct injection engines, this argument remains controversial because experimentation by some researchers has shown that lowering the compression ratio in susceptible engines by as much as 15 per cent does not affect the likelihood of low-speed pre-ignition occurring in such modified engines under high low/low engine speed conditions.

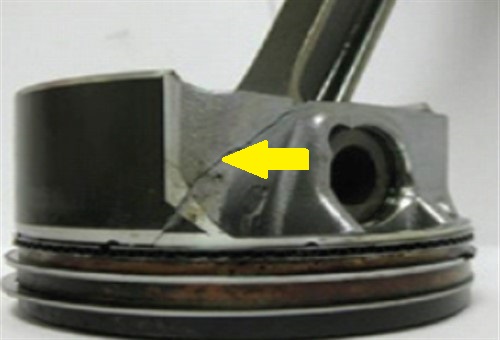

Whatever the causes of low-speed pre-ignition might turn out to be, though, low-speed pre-ignition produces extreme pressure spikes in combustion pressures before the pistons reach TDC, but more importantly, it occurs before the ignition spark is delivered. In severe cases, the effects of low-speed pre-ignition are roughly analogous to hydro-locking the engine while it is running, which explains the severity of the damage to pistons and connecting rods when it occurs. Below are two examples of fatal piston damage caused by low-speed pre-ignition-

Image source: https://www.motor.com/wp-content/uploads/LSPI_2_0117.png

This example shows how even a mild case of low-speed pre-ignition caused a piston to fracture, with the fracture line indicated by the yellow arrow.

The second example (shown below) shows how a severe case of low-speed pre-ignition caused a large section of the piston crown to melt and break away from the piston structure. In this instance, the extreme pressure and heat in the cylinder acted like a kind of blowtorch flame that forced its way into the space between the piston crown and the cylinder wall, as indicated by the red arrow-

Image source:https://www.motor.com/wp-content/uploads/LSPI_2_0117.png

So, apart from the destructive effects of low-speed pre-ignition on pistons and connecting rods, low-speed pre-ignition also has an insidious negative effect on timing chains, timing sprockets, chain tensioners, and chain guides. Here is the short version of how this process works-

Image source: https://www.valvolineglobal.com/en-ksa/what-is-lspi/

In practice, low-speed pre-ignition on downsized petrol engines can occur at almost any point during the compression stroke before the ignition spark is delivered. In most cases, low-speed pre-ignition does not only produce more chaotic ignition combustion conditions than detonation but the toxic cocktail of fluids and substances* in the cylinders during low-speed pre-ignition also produces relatively large amounts of soot, as opposed to hard carbon deposits.

*We will discuss this in Part 2 of this article.

Petrol soot particles are similar in size to diesel soot, and although the exhaust stroke expels a large percentage of this soot from the cylinders, the extreme pressure spikes caused by low-speed pre-ignition forces some soot particles into the space between the piston crown and the cylinder wall, and then past the piston rings to end up in the oil.

We mentioned elsewhere that GF-6 compliant engine oil formulations must contain minimum amounts of certain additives, and one such additive has the task of capturing petrol soot particles and they do this by enveloping the soot particles to keep them in suspension. However, although these additives are generally effective, the problem is that keeping abrasive soot particles in suspension allows the oil pump to force the particles to circulate throughout the engine.

Moreover, since low-speed pre-ignition produces large amounts of soot, the additives in the oil that capture the particles become saturated with soot particles very quickly, which presents an additional problem. This problem involves the fact that low-speed pre-ignition occurs most frequently at, or close to a small displacement direct injections engine's peak performance level, which means that if the soot-enveloping additives in the oil are partially depleted, the oil can quickly become over-saturated with soot particles.

The practical effect of this condition is that the engine could be deprived of protection against the abrasive effects of petrol soot particles just when the engine needs such protection the most, which begs this question-

In part 2 of this article, we will discuss the specific negative effects of low-speed pre-ignition on timing chains in small direct-injection engines, as well as the current state of knowledge about the in-cylinder conditions that could initiate low-speed pre-ignition in small direct-injection petrol engines.