In Part 1 of this two-part article we discussed the destructive nature of low-speed pre-ignition in small displacement direct injection petrol engines. Now, in Part 2, we continue the discussion on the role that low-speed pre-ignition plays in the accelerated wear rates of timing chains and associated components in small displacement direct injection petrol engines. Before we get to specifics, though, let us look at-

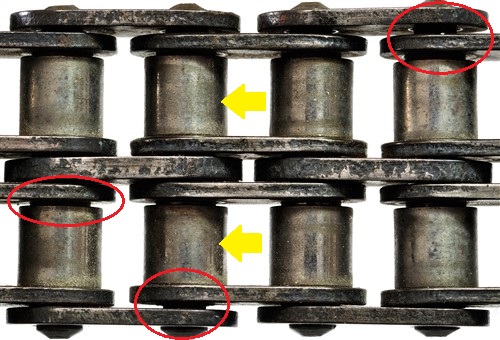

This image shows a close-up view of a section of a severely worn timing chain, as shown by the red ovals and yellow arrows. While we have all seen this degree of wear on timing chains, this particular example is a chain taken from a 1.0L DGI engine with barely 140,000 km on the clock. Based on this example, it would be reasonable to say that this is a premature timing chain failure.

In this case, the vehicle’s owner complained of-

- and most importantly, a noticeable knock or clatter in the engine upon acceleration at low engine speeds and high engine loads.

Upon investigation, this writer found that the timing chain had become so elongated that although the chain tensioner was fully extended there remained a significant slack in the chain. Moreover, it turned out that the camshaft phasing was out by nearly four degrees, which adequately explained most of the observed symptoms.

Taking all of the above information together, it was clear that this DGI engine was suffering from near-persistent low-speed pre-ignition, which created the conditions that caused extreme wear on the timing chain. It is perhaps worth noting at this point that the abrasive soot caused by low-sped pre-ignition can account for between 1 per cent, and as much as 30 per cent of the oil’s total mass, and a laboratory test showed that in this case, suspended soot accounted for just more than 19 per cent of the oil’s mass.

This is admittedly an extreme case, but the point is that DGI engines do not have special, wear-resistant timing chains. In practice, the timing chains in DGI engines are made in the same way that timing chains have always been made, in the sense that the same somewhat case-hardened metals are used in their construction. So, there are no special metals, no special wear-resistant coatings, and no special heat or chemical treatments to increase the overall wear resistance of components in the timing chains we see in small DGI engines, which explains the legal requirement for oil formulators to include targeted protection against timing chain wear in their API SP and ILSAC GF-6 oil formulations.

The laboratory analysis of the oil also provided other useful information. For instance, the oil in the engine was of the correct grade and formulation for this engine. However, the test report pointedly commented on the fact that the special additives whose function was to keep the soot particles in suspension were about 98 per cent saturated with soot, meaning that the engine, and by extension, the timing chain, had become almost completely deprived of this particular form of protection well before the next scheduled oil change.

So, what does all of the above mean? It simply means this: the combined effects of depleted oil additives and near-persistent low-speed pre-ignition created the perfect conditions for a poorly designed timing chain to be fatally damaged by oil that acted more like grinding paste than an advanced lubricant.

In practical terms, the rapid uptake of electric vehicles makes it almost certain that no car manufacturer will embark on the hugely expensive exercise of developing ultra-wear-resistant timing chains for small DGI engines. Nonetheless, in a market like ours, small GDI engines will be with us for a long time yet, so let us look at what is currently known about-

While there are plenty of theories about what causes low-speed pre-ignition in small DGI engines, most researchers seem to agree on one thing, which is that nobody knows for sure what causes the phenomenon of low-speed pre-ignition. Despite this, though, most researchers seem to agree on at least some of the contributing factors, but the physics of the process that actually ignites the air/fuel mixture prematurely remains unexplained since premature combustion can and does occur in the total absence of localised hot spots in the cylinders.

Nevertheless, below is a quick rundown on the factors that are thought to create the conditions required for low-speed pre-ignition to occur-

Using advanced monitoring techniques, researchers have found that direct fuel injection creates a non-homogeneous (non-uniform) mixture of air and fuel in the cylinders of some small DGI engines. Note that this non-uniform state must not be confused with the intended stratification of the air/fuel mixture under some operating conditions. In this context, excessive carbon build-up on the intake valves induces a swirl pattern in the inrushing air that disperses the fuel in a chaotic manner, which causes the mixture to ignite at multiple points throughout the mixture much like diesel ignites in a diesel engine. As might be expected, this causes poor or incomplete combustion but since the piston is still rising at the moment of ignition, the extreme pressure spike in the cylinder forces some of the resulting soot past the piston rings.

This is exacerbated by the fact that most, if not all small DGI engines use narrow, low-tension piston rings to reduce friction, meaning that it is not difficult for soot to be blown past the rings.

To be fair to oil filter manufacturers, filtering out petrol soot particles that are typically smaller than one micron is no easy task. As a practical matter, making oil filters that can filter out sub-micron particles will starve the engine of oil, which explains why car manufacturers rely on oil additives to trap and contain soot particles, as opposed to relying on simple mechanical filtration to remove soot particles from the oil.

Most researchers have found that low-speed pre-ignition is more likely to occur when the engine is running lean due to engine vacuum leaks or other defects that typically cause lean running conditions.

Using advanced laser interferometry techniques, most researchers have found that microscopic fuel and oil droplets combine with some oil additives under low engine speed and high engine load conditions to produce a highly combustible cocktail (during the compression stroke) that sometimes ignites even before the injection event begins.

Unfortunately, some of the additives that are involved in this process are legally required to be present in API SP and ILSAC GF-6 oil formulations to protect the timing chain. Thus, until suitable replacements for these additives are found or developed, the very additives that are needed to protect the timing chain are implicated in causing low-speed pre-ignition in many small DGI engines, which is ironic to say the least.

The few points outlined above represent almost the sum total of what is known or suspected to cause low-speed pre-ignition in small DGI engines, but it is worth noting that not all researchers agree on whether some or all of the above factors contribute to low-speed pre-ignition in all susceptible engines. We need not delve into the intricacies of these disagreements here, but suffice it to say that current methods to mitigate to prevent low-speed pre-ignition in small DGI engines turned out to be somewhat less than effective.

Such measures include using piston rings with higher inherent tensions to improve cylinder sealing, but the higher friction causes significant losses in engine efficiencies. Other methods involve changes in engine management programming, but such changes are limited by the engine design or by the design of the combustion chambers, piston crowns, or even the exhaust manifold, which begs this question-

Well, no, at least not to the extent where we can say to a customer that it will never occur in his small DGI engine. Therefore, the best things we can do for our customers is to educate them on the high prevalence of low-speed pre-ignition in small DGI engines and to recommend the following maintenance steps-

On a practical level there is nothing mysterious about premature timing chain failures in small, turbocharged DGI engines. Such failures are purely the result of cause and effect, where the cause largely involves the extreme demands of the Euro 6 emissions regulations, and the effect involves both inadequate lubrication and egregious cost-cutting measures by car manufacturers.

Such cost-cutting measures include using inadequate or poorly designed timing chains instead of wear-resistant gear trains to regulate the engine timing. To be sure, gear trains are much more costly to produce than timing chains, but then again, does this cost approach the cost of millions of warranty claims on prematurely failed timing chains the global car manufacturing industry has had to settle since circa 2011 when downsizing petrol engines became the norm?

We will likely never know the answer to such (and other) questions but for the moment, it helps to understand the main causes of low-speed pre-ignition, which until recently, was one of the most enigmatic problems on modern small engines.