New automotive technologies are being introduced faster than ever before, with new ADAS systems, as well as refinements and new features to existing ADAS systems being the most prominent- at least from our perspective as mechanics and technicians.

ABS functionality is a good case in point; most of us have mastered the basic operating principles of these systems and can diagnose and repair systems without much difficulty. However, tacking systems like traction and stability control, adaptive cruise control, and automatic emergency braking (and others) onto existing ABS systems has created a conglomeration of systems that is far bigger than the sum of its parts.

Much of what makes these systems work together as well as they do has to do with improvements in computing power. However, one unintended consequence of lumping various ADAS systems together, and then adding the lump of systems to the basic ABS system was that ABS systems could not (and often still don’t) react fast enough to satisfy the requirements of some ADAS systems.

To be sure, modern ABS systems are vastly superior to the systems of just ten years ago, but the speed with which even modern ABS systems react to brake inputs by drivers and feedback signals from wheel speed and other sensors is still hampered by the combined effects of the-

While the above is saying a lot about how modern brake systems work, all of it can be tied to the physical properties and characteristics of brake fluid as the medium through which pressure is distributed throughout the brake system. Thus, in this article, we will take a closer look at brake fluid in general, and the advent of new brake fluid standards that car manufacturers have developed to meet the demands of their particular versions of some ADAS systems, in particular. Before we get to specifics though, let us look at-

The biggest problem with the standards that regulate the physical properties and characteristics of brake fluid is not the standards themselves- the problem is that there are different standards, each of which is overseen and (sometimes) enforced by a different organisation. Here is the short version of who oversees and sometimes enforces what-

We need not delve into the complexities of these standards here, beyond saying that for the most part, all the standards listed here define the key characteristics all brake fluids must have in much the same way. Put differently, this means that in theory, any properly defined brake fluid will perform in much the same way as any other properly defined brake fluid under similar conditions.

However, the practice is somewhat different, and while we need not explore all the differences between brake fluid standards here, we can say that the most critical property of any brake fluid formulation, i.e., its viscosity, or resistance to flow under gravity, does not meet the demands and requirements of modern vehicles. Of course, there are other parameters that matter in brake fluid, such as wet and dry boiling points, but for the purposes of this article, we will focus solely on the viscosity of brake fluid, and in particular, on the viscosity of DOT 4 brake fluid, which is what we all commonly use in all vehicles, including late-model and new vehicles.

So, why is this important? You may well ask because we often think that since a brake fluid container says "DOT 4", it is safe to use in all vehicles. However, the fact is that many DOT 4 brake fluid formulations do not meet any of the performance standards that many, if not most major OEM manufacturers have lately set as the minimum standard to which brake fluids used in their products must conform, which brings us to-

The designation "DOT 4" does not refer to a specific brake fluid formulation but to a broad set of characteristics and properties that make them superior to DOT 3 brake fluids. These properties include (among others) improved corrosion protection, lower viscosity, and higher boiling points than DOT 3 brake fluids, and today, DOT 4 brake fluid formulations provide safe, reliable, and predictable service in many hundreds of millions of vehicles across the globe. So, what is the problem?

The problem is this; many of the hundreds of millions of vehicles older vehicles that have DOT 4 brake fluid in their brake systems were designed to operate on DOT 3 brake fluid. So, since DOT 4 brake fluid is largely backward compatible with DOT 3 brake fluid, many owners of older vehicles have upgraded their brake systems by switching over to DOT 4 brake fluid, which provides superior performance.

In the vast majority of cases, this does not present a problem, because the fluid dynamics of DOT 4 brake fluid improve in ABS systems with low cycling rates. In practice, when ABS systems were first invented, they were built around the physical properties of DOT 3 brake fluid, which had a relatively high viscosity. As a result, the first ABS systems on cars were limited to cycling rates of about 10 (or fewer) cycles per second due to DOT 3 brake fluids’ high viscosity.

In this context, the term "kinetic viscosity" a fluid flows under gravity when this is measured at different temperatures. In the case of brake fluid, this is measured at a minimum temperature of - 40 degrees Celsius, and then again at a maximum temperature of 100 degrees Celsius. Test results can be expressed as millimetres squared per second, or as "cSt", which is shorthand for “centistoke”, with 0.01 cSt being equal to 1 mm squared per second.

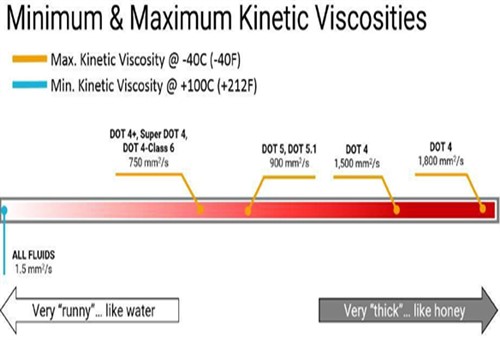

At this point, you may ask if there is a point to all of the above. There is indeed a point, and an important one, at that, but before we get to it, consider the graphic below-

Image source: https://greenlab.lt/wp-content/uploads/2021/01/Brake-Fluid-what-you-should-know.pdf

This graphic presents the viscosity characteristics of the major brake fluid DOT classifications, but since it does not tell the whole story, let us fill in the blank spaces.

All brake fluid standards specify that no brake fluid formulation can have a minimum viscosity at 100 degrees Celsius that exceeds 1.5 millimetres squared, which is indicated by the vertical blue line on the left of the graphic. This is to ensure that brake fluid remains "thick" enough not to seep past seals when the brake system is under pressure.

The other pertinent metric, i.e., the maximum viscosity any brake fluid can have at minus 40 degrees is indicated by the dark orange bars extending from the thick red bar. Note the orange bar that shows DOT 4 brake fluid; at minus 40 degrees Celsius, DOT 4 brake fluid is the most resistant to flow.

Although Australia will almost certainly never see temperatures this low, “standard” DOT 4 brake fluid is too “thick” to work in micro-valved ABS systems because the ABS controller cannot work at the required 16 to 20 cycles per second in the presence of brake fluid that to the system, is as thick as honey.

So, against this background, here is the point we are making-

If a human driver applies the brakes on a vehicle with a modern ABS system, it can take anywhere from 300 milliseconds, to about 600 milliseconds for the brake system to develop its peak pressure as a function of the pressure being applied to the brake pedal. Under these conditions, the fluid dynamics in the brake system caused by the displacement of a small volume of brake fluid as the caliper pistons move towards the brake rotor, are relatively simple.

However, if the ABS comes into operation and begins to cycle at up to 20 times or more per second, the rapid movement of the brake fluid in the system (as the brakes are applied and released) sets up hydrodynamic forces in the brake fluid that strongly resemble the forces that allow engine oil to create the pressure waves and hydrodynamic wedges that maintain effective engine lubrication, In practice, these forces have a severe delaying effect on the pressurising phase of each ABS cycle, thus reducing the overall effect of the braking force being applied to the calipers to a measurable degree. This effect is roughly analogous to how reflecting pressure waves in intake manifold runners reduce the effective flow rate of intake air through the intake system.

In the case of brake fluid, however, there is a direct correlation between the viscosity of the brake fluid and the speed at which pressure waves propagate through the brake fluid. So, essentially, each time the pistons in the calipers retract during ABS operation to release the brakes, the displaced brake fluid moves back toward the ABS controller, and although modern ABS controllers have mechanisms that largely damp out the incoming pressure waves, these pressure waves cannot be damped out or absorbed completely.

Thus, some of the energy in the outgoing pressurizing phase of each ABS cycle is cancelled out by the remaining energy of the incoming pressure wave, but the rapid movement of the piston(s) in the ABS controller also causes significant cavitation to occur in the brake fluid inside the ABS controller. Given the nature of cavitation in fluids, this further reduces the energy in the pressurizing phase of each successive ABS cycle.

Given the chaotic fluid dynamics in a modern brake system, it might seem that modern brake systems only work by some kind of miracle, but there is a more mundane explanation. Modern brake systems that use DOT 4 brake fluid work because the overall design of the brake system is based on a series of complex tradeoffs between factors that include, among others-

Thus, if the designer of a brake system gets all the tradeoff right, the resulting brake system will deliver at least the minimum acceptable braking performance that regulatory bodies in major automotive markets expect to see. However, an average driver will never know if the brake system in his new vehicle works at the system’s theoretical maximum capacity, or not. It might work at 95 per cent of its theoretical capacity, or 90 per cent, or even 85 per cent, but it does not really matter as long as the vehicle stops in the legally required distance.

This is an important point because a human driver can never apply the brakes in any modern vehicle as effectively as a computer can, which is what happens when a computer activates and controls the stability control system or more importantly, the automatic emergency braking system.

As its name suggests, the function of an automatic emergency braking system is to apply and use a vehicle's maximum available braking power to mitigate an emergency, such as an impending collision, and it simply cannot do that if the viscosity of the brake fluid in the brake system sets up hydrodynamic forces that actively inhibit the operation of the ABS system.

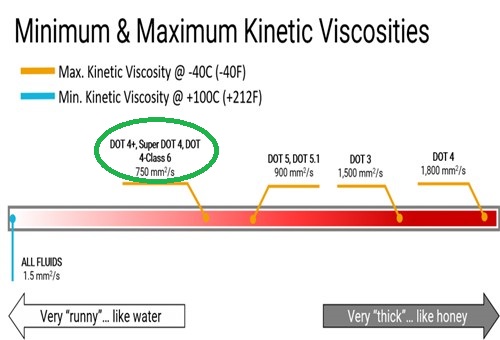

On the upside, though, there is a solution to this problem that does not involve complete redesigns of existing brake systems, so let us consider this image again-

Image source: https://greenlab.lt/wp-content/uploads/2021/01/Brake-Fluid-what-you-should-know.pdf

The green oval indicates the solution to the problem of excessively viscous brake fluid. To be sure, it is still DOT 4 brake fluid, but it is a completely “redesigned” DOT 4 brake fluid that is almost 50 per cent less viscous than the normal DOT 4 brake fluid we know and use daily.

However, its vastly reduced viscosity is only one half of the story. The other half involves its class 6 designation, which refers to its formulation, which, unlike previous DOT 4 formulations, is now built around the very specific requirements of what car manufacturers call "material standards".

"Material standards" is a somewhat ambiguous term, because, on the one hand, it refers to a requirement that class 6 brake fluids cannot contain ingredients that degrade any materials used in a given brake system. On the other hand, the term refers to the requirement that all class 6 brake fluids must conform to the material standards that a given car manufacturer specifies such a brake fluid must have in terms of its physical and chemical properties, as well as minimum performance standards in all operating conditions.

This is particularly important in the case of electro-hydraulic brake systems that are now being introduced on some vehicle makes and models. These systems can develop peak braking pressures in only about 120 milliseconds, but to do this, they need brake fluid that transmits pressure instantly. More importantly, these systems need brake fluid that does cavitate in the ABS controller or set up chaotic fluid dynamics that effectively absorbs some of the peak pressure in the brake system.

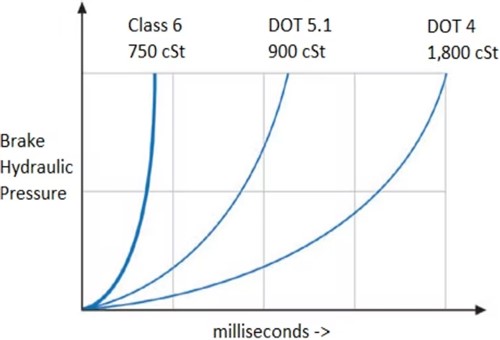

We can put the superior performance of class 6 brake fluid into proper perspective with the graph shown below-

Image source: https://www.vehicleservicepros.com/service-repair/underhood/article/21285234/new-class-6-and-class-7-brake-fluids-are-here

This graph, which was extrapolated from actual test results performed by independent researchers, shows that class 6 brake fluids react to pressure inputs almost instantly, although an average human driver is incapable of recognising the difference between the performance levels of DOT 4 class 6 brake fluid, and “normal” DOT 4 brake fluid. Nonetheless, the difference demonstrated here translates into the difference between an automatic emergency braking system successfully preventing a collision, and an automatic emergency braking system merely slowing the vehicle down before the collision occurs, which brings us to-

We could list the requirements of some of the material standards relating to class 6 brake fluids that most major car manufacturers have published in the recent past but that would be rather pointless. This is because they all state the same thing, which is that proper operation of the brake system on modern vehicles can only be guaranteed if the correct brake fluid is used.

Two other points are in fact, more relevant to our jobs as mechanics and technicians. The first is that we need to look past "DOT 4" on brake fluid containers and look for the class 6 designation that indicates that the brake fluid we are planning to put into a customer's car conforms to the car manufacturer's requirements.

The second point is perhaps more important. This point involves the fact that the Department of Transport, which is the “DOT” in brake fluid, has not yet evaluated, tested, or approved any class 6 brake formulations for use in the USA. The only organization that has actually tested and approved class 6 brake fluid formulations is the ISO (International Organization for Standardization), and this approval is contained in their ISO 4925 document.

Let us look at two examples of the information that should be listed on brake fluid containers-

1) Modern Ford vehicles require approved “Motorcraft DOT 4 LV” brake fluid that conforms to Ford’s material standard WSS-M6C65-A2, which includes the class 6 viscosity specifications as described by ISO 4925.

2) Modern VAG-group vehicles require brake fluid that conforms to VW/Audi’s material standards “TL 766 Z” and “501 14”, both of which include the viscosity requirements as specified in ISO 4925 in addition to the standards that apply to DOT 4 brake fluid, which leaves us with this-

There is also a class 7 brake fluid with even more stringent viscosity requirements, and while this highly advanced brake fluid is not yet in widespread use, it will almost certainly become the norm once F1-derived electrohydraulic brake systems become more prevalent than on the few road-going Mercedes, Lexus, Corvette, and Alfa-Romeo models that are currently equipped with such brake systems.

Although we in the independent repair industry will likely not see many F1-derived braking systems in the immediate future, it is as well to remember that the modern brake systems we do see are several orders of magnitude more advanced than the brake systems of a decade ago. Therefore, the last thing we want to do is to reduce their efficiency by using inferior brake fluid.