Many of our customers base their vehicle purchases solely on fuel economy, while many others are only concerned with how many horsepower their vehicles make on the one hand, and how this number can be increased to near-magical levels, on the other. While it is not our place to question the choices our customers make, the choices they do make can sometimes lead to difficult questions; such for instance, a customer wanting to know how many horsepower he can gain by making certain exhaust and/or engine modifications.

There are no simple answers to questions like this, and it has been this writer’s experience that the easiest way to avoid interminable discussions with clients about possible power gains is to answer with this question “What do you want to increase, horsepower or torque?” The distinction between the two terms is not always clear to many car enthusiasts (and sometimes to mechanics, as well) and popular car-oriented publications often add to the confusion. Thus, in this article, we will explore not only the differences between horsepower and torque but also why neither term can be used without referencing the other. Let us start with this question-

This image illustrates the basic principle of the engineering term "horsepower", which can be reduced to how much work one horse can do in one minute. However, to understand how this concept was arrived at, we need to make a brief historical detour to the time the term was coined. Here is how it happened-

You may or may not know that James Watt did not invent the steam engine. That honour goes to Thomas Newcomen, who constructed the first, albeit inefficient steam engine in 1712. What James Watt did do, however, was to improve Newcomen's design to the point where in 1764, his steam engines used 75% less coal to produce the same amount of power as Newcomen’s engines did. The problem was, however, that Watt needed to monetise his improved design, so he hit on the idea of developing a standardised unit of power that could be used to express the power output of his engines, while at the same time, illustrating their thermal efficiency- albeit in a roundabout way.

Thus, since the Industrial Revolution was still largely dependent on the power of horses to move, carry, and transport materials and products in the mid-1700s, Watt devised an objective way to measure the amount of work one horse could do in a given time. This method involved a system of ropes and pulleys, a mineshaft, and horse to lift a bucket of coal weighing 366 pounds. Here is how it worked-

Watt connected the bucket of coal to his horse via the ropes and pulleys and measured the time it took the horse to lift the bucket up the mineshaft at the rate of one foot per second, and it turned out that the horse could lift the bucket of coal to a height of 60 feet in one minute. Expressed differently, this meant that the same horse could lift 21 960 pounds to a height of one foot in one minute (366 [pounds] multiplied by 60 [seconds] = 21 960), which became the accepted value of “1 horsepower” until 1782, when Watt used a stronger horse to arrive at a value of 32 400 foot-pounds/minute. Watt rounded this off to an even 33 000 foot-pound/minute, and this value is still used today, which begs the question of -

While factory owners in Watt's day were mainly concerned with how many horses they could replace with a high-tech steam engine, modern-day car manufacturers use the horsepower ratings of their engines almost exclusively as marketing tools, thus creating much confusion about the power output of their products in the minds of car buyers, who often confuse horsepower with torque.

Before we get to the specifics of how horsepower relates to modern engines, we should perhaps mention the fact that “horsepower” as a unit of force, cannot be measured directly. It can only be calculated using this formula: Horsepower is equal to Torque multiplied by Engine Speed, divided by 5 252*.

*The figure 5 252 is a mathematical constant that always refers to engine speed (RPM), and is derived from the complex mathematical relationships between power, torque, and velocity. In the context of modern car engines, these terms/concepts are defined as follows-

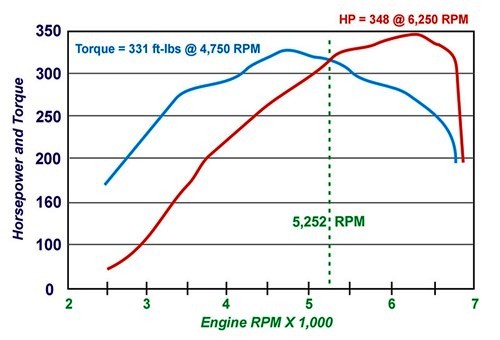

We need not delve into the complexities of these relationships here, beyond saying that the constant of 5 252 is the engine speed at which the plotted values of torque and horsepower always intersect on a graph because, at that point, horsepower and torque are equal. Note though that this rule only applies to engines that are capable of rotational speeds that exceed the value of the constant, i.e., 5 252 RPM.

With that out of the way, we can focus on horsepower as a unit of measurement, and how it relates to torque.

Harking back to James Watt’s experiments, we can reduce the concept of horsepower to the simple idea that any horsepower rating refers to how much work any given engine can do in a fixed amount of time. However, horsepower cannot exist in isolation because it is directly proportional to the level of torque the crankshaft generates at any given engine speed, which in turn, is proportional to the engine’s displacement and volumetric efficiency.

Put in another way, we can say that horsepower is a function of torque, which in its turn, is a function of an engines’ design in terms of among other things, stroke length, piston diameter, the degree of pumping and frictional losses, and the efficiency of the exhaust system, which begs this question-

Since torque and horsepower are closely related, anything that affects the one will necessarily affect the other so the better question would be, “What is it you want to achieve?”

Let us use a practical example, but note that for our purposes, we will ignore variables such as transmission gearing, vehicle weight, and the calorific values of different fuels, but before we get to the specifics of the above question, let us explore the concept of torque-

Put simply, an engines’ torque rating is an indication of how much work that engine can perform by applying a twisting force to the crankshaft, but note that this value is independent of time. Think about torque this way; if you are approaching a highway on an on-ramp, torque is what gets you up to highway speed, and horsepower is what keeps you moving at highway speed.

If we apply this distinction to our everyday experience, we can use it to explain why the engine in something like an 18-wheeler truck develops only about 400 or so (or sometimes less) horsepower, but 2 000 Nm (or more) of torque, despite the close relationship between horsepower and torque. At first reading, the huge discrepancy/difference seems counterintuitive, but here is how it works-

Because of its design, a large diesel engine develops most of its torque at engine speeds just above idling, because of among other things, the relationship between piston diameter and crankshaft stroke length. Therefore, since most of its power is already available at very low engine speeds, the engine does not have to perform lots of work or put differently, generate many horsepower in short periods. As a practical matter then, the engine only has to generate enough horsepower to maintain the truck's momentum at relatively low road speeds while carrying 50 or 60 tons of cargo, because the engine’s already high torque output is greatly amplified by the gear ratios in its transmission and final drive(s).

By way of contrast, the engines in passenger vehicles have to be capable of accelerating vehicles at high rates, which is accomplished by high torque outputs. However, high torque outputs mean that such engines have to be able to perform more work in shorter periods, but there is a problem with this. In practice, torque depends on engine speed while horsepower does not; horsepower depends on much work an engine can do in a given time, so at a particular point in the engine’s operating range, torque begins to drop off because of a drop off in volumetric efficiency.

The biggest single cause of this drop-off is the fact that as engine speed rises, it becomes progressively more difficult to fill the cylinders with air. In practice, all naturally aspirated engines stop producing torque* at the point where pistons are moving so fast that the air flowing through the intake system can no longer move fast enough to keep the cylinders filled with air and fuel. This point is typically referred to as an engine’s peak torque point, and it is different for all engines.

* Engines with forced induction are much less susceptible to this phenomenon, or sometimes not at all, due to these types of engines’ volumetric efficiency, which can exceed 100% by a wide margin.

Nonetheless, consider the graph below-

Image source: https://www.searchautoparts.com/sites/default/files/images/8%20Dyno%20Chart%205252%20Cross.jpg

The above graph plots the horsepower vs. torque ratings of a typical mid-sized SUV with a petrol engine. While the specific vehicle is irrelevant to this article, it should be noted that the two values intersect at 5 252 RPM, as it should for all such plots. Note also that maximum torque is achieved before the intersection point (at 4 750 RPM) and that up to that point the torque and horsepower plots are almost parallel. Torque begins to drop off after 4 750 RPM until the intersection point, after which horsepower continues to rise until the engine reaches a speed of 6 250 RPM before dropping off sharply.

This general pattern occurs on all engines and while specific values vary between engines, horsepower will always be higher than torque after the intersection point, because most engines are capable of producing work per unit of time after the peak torque point. Just how much more work any given engine can do per unit of time after this point depends not only on the engine design (and its volumetric efficiency) but also on the limitations that are inherent to reciprocating systems. In translation, this means that at some point, a reciprocating system can no longer add energy to the system, regardless of how much potential energy is put into the system, which in this case, is fuel and air.

One particular (extreme) example of horsepower being much higher than torque after the intersection point is modern F1 engines. These engines cannot develop much torque at low speeds because their crankshafts have strokes that are on average only 40mm long, so to compensate for low torque at low engine speeds, these engines are capable of producing enormous amounts of energy (work) per engine revolution/unit of time. This is because of a) their 15 000-RPM maximum engine speeds, and b), their high volumetric efficiency that in combination, produce around 950 horsepower, and torque values in the 240 Nm to 260 Nm range, which brings us to the issue of-

So your customer is still waiting for you to tell him what his proposed modifications will accomplish, but bear in mind that the answer to the question, which is better, horsepower, or torque, depends entirely on what your customer wants to achieve with his proposed modifications.

There are no simple answers to this question, but if this writer can offer one suggestion, it would be this; tell your customer not to chase horsepower for horsepower’s’ sake, simply because horsepower (as a unit of force) is a function of torque. This is true regardless of whether your customer wants to convert his daily driver into a race car, or wants to turn a sedate pick-up truck into something that can climb vertical rock faces.

What your customer wants to achieve probably falls somewhere between these two extremes but since the same principle applies to all cases, you could perhaps quote Newton's First Law. This law states that an object (a vehicle in this case), will remain at rest on in constant motion unless an external force acts upon it to either get it moving or to change its rate of motion.

Thus, increasing torque gets a vehicle off the starting line faster because the modified engine can supply a higher twisting force than a standard engine can, which has the further effect of accelerating the vehicle at higher rates for longer. Depending on the level of modification, and of course, transmission gearing, maximum toque might now be achieved at say, 5 800 RPM, as opposed to say, 4 750 RPM as in our example graph.

Note though that the horsepower and torque plots of our hypothetically modified engine will still intersect at 5 252 RPM, but the horsepower plot will rise for more RPMs (and likely more steeply) after the intersection point than in our example because of the increased efficiency of the modified engine, which leaves us with this-

The key to providing relevant and accurate information about engine performance to customers is to understand what it is they want to achieve by making modifications to their vehicles. For instance, some may want additional torque at low to mid-range engine speeds to make it easier to tow heavy trailers and boats at low to moderate road speeds, while others may want a “flat” torque curve to enable high rates of acceleration even at high engine speeds, such as might be required during a race event.

The relationships between torque and horsepower will differ greatly for these two applications, but in both cases, increased torque will be the primary driving force behind the performance improvements, while increases in horsepower will merely be an expression of how much more work the modified engine can do per unit of time as compared to a standard, unmodified engine.