It is a universal truth that in any group of people that engage in the same activity, there is always one individual who is better at that activity than anyone else in the group. In the case of the car repair industry, we often describe that singular person as a "master mechanic", but did you ever wonder just what it is that differentiates a master mechanic from a competent or even an outstanding mechanic? Is it having a portfolio of certificates like the one shown here, or owning mountains of tools and gadgets to tackle every imaginable job? Is it about knowing more than anybody else in the workshop, or is it the ability to turn around more vehicles every day than anybody else in the workshop?

There are various theories and schools of thought about what it takes to be a master mechanic, and although a multitude of studies have shown that all of the above attributes are important, they are not of equal importance to everyone, nor are they weighted equally in all situations or in all workshop environments. Nonetheless, we all strive to be the best mechanics we can be under sometimes-trying conditions and with this article, we will show that is possible not only to be a good mechanic, but a master mechanic without the need for reams of certificates or mountains of tools. Let us start by saying that-

The title of this heading should not be taken to mean that some trade schools in Australia provide some aspiring mechanics with a standard of training that does not equip them with the skills and knowledge required to function in a professional environment. All trade schools in Australia are obliged to adhere to minimum standards in terms of both the standard and depth of training they provide, and it is, in fact, rare to find a trade school that does not adhere to the required minimum standards.

That said, though, many trade schools provide training at levels that exceed the minimum standards by a wide margin. In some cases, the instructors at these schools are experienced ex-technicians, or experienced professional technicians that teach on a part-time basis, and as such, these instructors are acutely aware of what new mechanics need to know to cope with the demands that a modern professional environment places on mechanics.

So to properly equip trainee mechanics, the training programs provided by some top-end trade schools often compare favourably with the training programs that OEM manufacturers follow in their in-house training facilities, so in such a trade school, you will typically receive-

Sadly, though, there is another side to trade schools, and you probably experienced it firsthand during your first few months working for your own account, so to speak. This side of trade schools involves the fact that although you may have received the best possible training, a trade school can never adequately prepare you for the self-doubt and lack of confidence that many, if not all new mechanics experience when they start their careers.

Moreover, a trade school, even a top-end trade school, may also not equip you to deal with your new (and almost-always, more experienced) colleagues’ lack of faith in your knowledge and diagnostic skills. Then again, it is not the job of a trade school to prepare you for the psychological aspects of life as a new mechanic, but if you now think back on your first few months of being a professional mechanic, how would you answer these questions-

1) Did you feel the mechanical and electrical theory you learned equipped you to work without supervision?

2) Did you use any of the laws of electricity you studied to diagnose electrical problems, or did you need assistance with reading schematics? More to the point, though, how easy or difficult was it for you to relate scale-less schematics to actual wiring topologies?

3) Did you feel you studied enough theory, or did you think that you did not need much of the theory you learned because you could figure things out for yourself?

4) Could you use your practical training to determine in which way mechanical parts were defective, and particularly when parts were not actually broken, fractured, seized, burnt, or shattered?

5) Did you know enough mechanical and electrical theory to reduce problems and issues to their simplest form?

6) How many times did you ask for any form of assistance from more experienced mechanics during the first month of your professional career?

There are no right or wrong answers to these questions: only honest answers. However, if you were honest with yourself, you'd likely admit that finding your feet during the first few weeks and months of your career were difficult because you did not know enough about the vehicles you worked on during this time. As a result, you often doubted your diagnoses and frequently wished that you knew more about (insert what you wished you knew more about here) than you knew at the time.

You likely also doubted your career choice, but if the truth were told, most of us have done that many times in our careers. Nonetheless, if you were again honest with yourself, you would recognise that if it were not for a) the training you'd received in trade school and b), the assistance of more experienced mechanics, you would not have had the solid foundation you needed to build on to become the skilled mechanic that you are today.

Having said that though- do you want to remain only a skilled mechanic, or do you want to become a master mechanic in a few easy steps? Note though while nothing worthwhile in life ever comes easily, you can easily raise your skill level by following these three tips-

Image source:https://www.searchautoparts.com/sites/default/files/images/MA0820-3%20copy.png

This is more of a philosophy than anything else, and at the heart of it lays the fact that in their simplest form, all cars are the same* beneath their metal skins. All car engines need fuel, cylinder compression, and an ignition source to run. All cars also need brakes to stop, a steering system to go around corners, and a suspension system to smooth out the ride.

* While hybrid vehicles, electric vehicles, and plug-in hybrid vehicles differ from conventional vehicles in meaningful ways, all hybrid vehicles, electric vehicles, and plug-in hybrid vehicles are sufficiently similar to each other to be included in the notion that all cars are essentially the same.

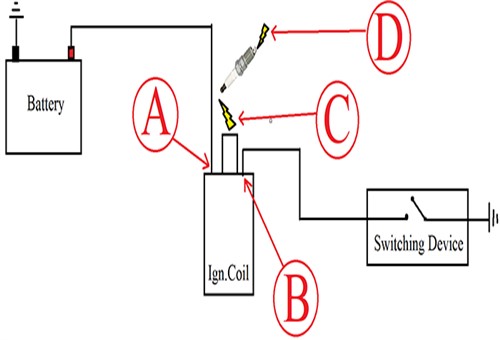

Consider the simplified schematic of an ignition system above. While this schematic is grossly oversimplified, it does illustrate the point that any process on any vehicle consists of a series of steps, all of which have to complete successfully before the next step in the series can be initiated or completed. You may already know this on an intuitive level, but how often does it happen that we forget the consequential nature of control and monitoring functions on modern vehicles?

It is when we forget that every action has to be preceded and followed by other actions that the shotgun approach to diagnostics becomes attractive. Sadly, diagnostic flow charts often encourage this approach, even from experienced mechanics, because flow charts seldom start at the beginning of say, a random misfire problem. So what does this have to do with ABC’s?

Simply this; if you remember that a) all ignition systems follow a general pattern, and b), that all ignition systems work in much the same way, you will also remember that all ignition systems typically fail in similar ways. Therefore, when you encounter, for instance, a misfire, you don't have to remember the specifics of every ignition system you have ever worked on, because ignition systems are at least 85% similar* across all vehicle brands.

* At least 85% of what happens on a vehicle during any given moment, is happening on all other vehicles under similar operating conditions as the result of physics and other laws of nature. While car manufacturers cannot change the laws of nature, they can change how some processes are implemented or executed, so while the result is the same on all vehicles, some proverbial roads leading to Rome may follow slightly different routes.

Thus, all you have to do is to focus on the relatively small differences between system designs while you a) follow the current through the ignition system along the only path(s) the current can follow, and b), use only the most productive entry points into the system to obtain test readings.

For instance, on some, if not most Asian vehicles, COP coils are so heavily potted that a KV probe might not pick up an induced magnetic field, so you have to use a separate KV probe lead with a clamp on the short plug lead to test a coil. Similarly, if you want to test for possible fuel injector involvement in a misfire, it helps to know if the injectors on that particular vehicle are controlled though battery positive or through a ground connection that is supplied by the ECU. This bit of knowledge can help you avoid spending time testing the wrong circuit(s) when you don't have a wiring diagram or other service information.

We can list many other examples here, but the point is that if you know your ABC's in terms of how systems work, you can eliminate some causes of problems almost immediately because some causes of problems or failures are simply not possible on some systems. This brings us to our second point, which is to suggest that you-

We all have different ways of approaching diagnostic problems, and most of them work most of the time under most circumstances. Sometimes, however, we run into problems that are remarkably resistant to our usual diagnostic approaches and processes that suddenly no longer work.

We have all had such experiences; misfires that defy resolution, odd vibrations that don’t happen when we test drive a vehicle, unexplained increases in fuel consumption, or this writer’s favourite mystery, disappearing engine coolant. We can sometimes spend days looking for answers to these and many other questions and issues, but what if we could develop a method to diagnose these kinds of issues quickly and consistently? Wouldn’t that be great?

Unfortunately, though, there is no such method, but we can do the next best thing, which is not to ask what is wrong with this vehicle, but to a) ask what has changed on the vehicle, and b), to ask if anything has changed recently. The answers to these questions can sometimes hold all the diagnostic clues you might need because just as individual parts or components on seemingly identical vehicles wear differently, entire vehicles also wear out or age differently.

Consider this example of a holistic approach to diagnostics: how likely is it that a vehicle that had obviously not been serviced regularly will develop "sudden" excessive oil consumption issues? In the real world, it is far more likely that the vehicle had been using progressively more oil for a long time, but it had now gotten to the point where the owner is starting to complain about it. In such a case, changing the oil, and sealing the oil filler cap to measure oil consumption over a set distance or mileage is pointless, and a waste of time.

On the other hand, how likely is it that a vehicle that is in an almost mint condition will develop a sudden severe vibration, unless that vehicle had either been abused or been damaged by, for instance, hitting a pothole in the road? Of course, severe vibrations do sometimes appear suddenly in the real world, but a car owner who clearly takes care of his vehicle will almost certainly not allow vibrations to get progressively worse for days or weeks before seeking professional assistance to diagnose and repair the problem. Therefore, vibrations that appear suddenly almost certainly relate to recent, once-off events, as opposed to a long-standing problem like a worn steering component that had caused secondary damage to suspension components.

So what does all of the above mean in practice? It simply means that if you consider the overall condition of a vehicle, and relate what you see to the problem, the cause of the problem will often jump out at you. In fact, this method of diagnosing problems does not only apply to the examples mentioned here: many driveability issues stem directly from poor or patchy maintenance practices that lead to unevenly worn tyres, transmission problems, engine overheating, and poor braking/steering responses, among many others, including electrical issues caused by poorly installed aftermarket accessories.

Here’s the thing though: we all know all of this at an intuitive level, but how often do we use what we see as diagnostic aids? By rights, diagnostics should involve all our senses- smell, touch, hearing, and even taste (in rare cases) but in practice, we often overlook the most obvious diagnostic clue(s), which is the overall condition of the vehicles we work on.

At the risk of overstating the case, we can conclude this section by saying that a small, but significant change in how we approach diagnostics could yield results that far outweigh the trouble of learning to look before we leap into potential diagnostic rabbit holes. You might also begin to look like some sort of magician who can diagnose all manner of problems just by looking at a car, but this last bit does take some practice before you get it right every time. Nonetheless, this brings us to our last point, which is to-

We are not talking about spanners, screwdrivers, and sockets here; one high-quality socket will undo a stubborn bolt as well as any other high-quality socket will. We are talking about your diagnostic tools: gas analyser(s), scan tools, multimeters, oscilloscopes, refractometers, pressure transducers, and sensor simulators. You may own other types of diagnostic tools not mentioned here, but we are sure you understand what we mean.

Note that we are not suggesting that you should now go out and buy every kind of tool that is available on the market, because none of us can afford that. What we are saying, though, is that if you do buy a new tool, then buy the best of its kind that is available, as opposed to buying the best tool of its kind you can afford. This is crucially important because you cannot trust test results that were obtained with poor-quality tools.

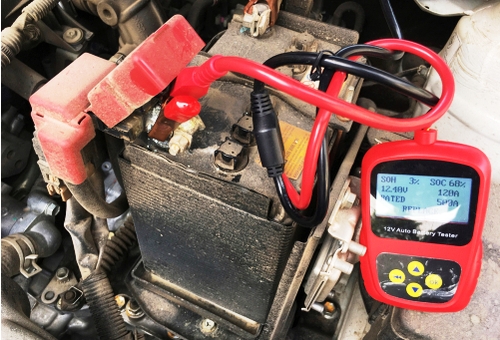

One other crucially important aspect of tools to bear in mind is that you a) need to know how to use them, and b), that you need to be aware of the limitations of your tools. We are not suggesting that you don't know how to use your tools to their best effect. However, if you are not an auto-electrician, are you aware of the fact that even a premier quality multimeter only displays average values that are not necessarily an accurate reflection of what is happening in a circuit?

Consider this example of how the typical multimeters we use everyday work. If you have a high-end multimeter, it will almost certainly have a sampling rate of only 250 microseconds, which means that the tool takes forty measurements of an electrical value every second. Thus, when you see a displayed voltage value of say, 12.5V, what you see is the average value of the electrical potential between the two leads as the tool measured it forty times over one second.

Given the tool’s sampling rate over one second, we can interpret this result in at least these two different ways. For instance, if the electrical potential between the two leads is actually 12.5V, the tool will have measured this value for only 50% of the time, or, the tool will not have measured any difference in electrical potential for the other 50% of the time. Therefore, if you are testing a circuit in which the switching rate is as fast, or faster than the tools’ sampling rate* you might end up not registering any potential electrical differences in that circuit at all.

* The switching rates of air/fuel ratio sensors are good examples of this possibility.

So, in practice, you cannot trust the results from one of your tools for at least some kinds of measurements, not because you did not know how to use the tool but because you may not have been aware of that particular tool's limitations. Oscilloscopes have similar limitations you may not be aware of. For instance, if you are using an oscilloscope to do a relative compression test using battery drains to indicate maximum compression, you might end up with false or misleading test results if, among other things-

Oscilloscopes cannot compensate for factors like these; it will display the information as voltages over time based on the inputs it had received. Therefore, if the tool calculates a display from defective, inaccurate, or invalid inputs for the test you are performing, the results cannot be accurate or relevant. Thus, if you want to trust your test results, knowing and understanding the limitations of your diagnostic tools is as important as using high-quality tools in the first place, which leaves us with this-

Not everyone can be a master diagnostician or become one overnight, simply because our brains are all "wired" in different ways. Of course, this is not the same as saying that most of us cannot become at least competent diagnosticians, because we can all learn from our mistakes and adapt to changing environments and technologies.

We must also say that while the tips outlined above might not make you a master mechanic in a matter of days, what we are hoping it will do is inspire you to learn more about the art and philosophy of modern diagnostics. This approach to diagnostics cannot be taught in trade schools and training courses: the only way to master the philosophy of modern automotive diagnostics is to live it firsthand and to apply what you learn every day on your journey to becoming a master at what you do.