To comply with increasingly stringent emissions regulations, diesel engines in light vehicles are required to be fitted with very expensive engine management and exhaust after treatment technologies, the cost-of-ownership implications of which are not always explained to first-time buyers of diesel vehicles. The result of this that we, as technicians, sometimes have the very unpleasant task of explaining the high maintenance cost of these vehicles to irate customers. This is not always easy to do, but if you have to explain high repair bills to owners of diesel vehicles on a regular basis, this article will supply you with some ammunition with which to mount a defence against accusations that you are trying to rip people off. Let us start with-

Despite proposed bans on the sale and use of diesel powered vehicles in large parts of Europe, there is no doubt that Australia is still very much in love with diesel vehicles for a variety of reasons, not the least of which is that diesel vehicles are on average between 15% and 30% more fuel efficient than comparable petrol models.

Much of the increased fuel efficiency over petrol engines has to do with the quality of the fuel used. However, while diesel vehicles in Europe and the USA consistently deliver huge fuel savings because of the high quality fuel that is available there, the fact is that Australia is known for the poor quality of its diesel fuel, although some strides have been made to improve the situation during the past decade or so.

Nonetheless, the quality of diesel sold to Australian consumers is still poor enough to contribute significantly to increased wear and damage of not only not only injection equipment, but also to exhaust after treatment systems/components such as diesel particulate filters, which begs the question why Australian diesel is as bad as it is. There are several reasons for this, but to put the matter in some perspective, we need to know what current Australian legislation prescribes for diesel fuel in terms of quality and cleanliness-

Amongst other things, the law requires that all types of mineral diesel* sold in Australia contain no more than 0.05% water and sediment by volume, as determined by the ASTM D2709 test method. In theory, this amount of water will not cause harm in the form of corrosion and/or excessive wear to injection equipment, but in practice, almost any random sample of Australian diesel will contain more water and/or sediment than the prescribed maximum, with corrosion and subsequent damage to pumps and injectors being an almost inevitable result.

*The current legally allowed water and sediment content of biodiesel is 0.05% by volume, while distillation residues are limited to 0.30% by mass. In practice though, the biodiesel in blends sold in Australia frequently do not meet these maximum limits, with the result that the total water/sediment content of diesel/biodiesel blends frequently far exceed the maximum allowable concentrations.

Worse, though, samples of diesel and biodiesel blends taken from remote locations will almost always contain vastly more water and/or sediment that the maximum allowed by law, simply because the longer distribution chains to these locations offer more opportunities for contaminants to enter the fuel.

The nett result of all of the above is that the poor quality of Australian diesel fuel is the single biggest cause of damage to, and/or premature wear of, injection pumps and fuel injectors, thus making a significant contribution to the high maintenance costs of diesel vehicles, which begs this question-

According official Australian Government sources, the country imported 1.6 billion litres of diesel fuel in May of 2017, with similar quantities being imported to date, since the existing refineries in Australia cannot supply the domestic demand for diesel fuel. Most of this fuel is imported from Singapore, but much of it is produced in Japan, South Korea, and other Asian countries and stored in Singapore for export to Australia. While there is nothing wrong with importing fuel in principle, there are several severe issues in practice, all of which influence the maintenance costs of diesel vehicles in Australia in the worst possible way. Let us look at the two most important issues-

There is simply no telling how many times diesel fuel that is produced in say, South Korea or Japan is decanted, transhipped, or otherwise transferred from one holding facility to another before it arrives in Singapore, from where it is transported by ship to Australia. There is also no telling how much water, solid particulates, and microorganisms and/or bacterial colonies is/are added to the fuel during each transfer, but based on the overall poor quality of Australian diesel, contamination must be significant during each step in the process.

Diesel fuel cleanliness standards in Europe and the USA are mainly driven by advances in diesel engine and fuel injection technologies. For instance, the ultra-high injection pressures of modern common rail injection systems are only possible because operating clearances in injection pumps and injectors have been reduced to the 2 – 4 micron range. Thus, unless a prudent Australian diesel vehicle owner fits a secondary 2-micron fuel filter to his fuel system, the solid particulates and water droplets that pass through standard 10-micron fuel diesel filters can cause irreparable damage to pumps and/or injectors.

Moreover, high injection pressures and small operating clearances require fuel additives in the form of conditioners, lubricants, deposit modifiers, biocides, corrosion inhibitors, and stabilisers that are generally not present in diesel fuel that is imported from Asia. While these additives are legally required ingredients of European and American-made diesel fuels, this is not the case in Australia, and therefore, Australian consumers are obliged to resort to adding expensive aftermarket additives to diesel fuel themselves to prevent excessive wear in injection equipment.

More to the point though, since aftermarket additives are not created equal, Australian consumers are often caught between the outrageous efficiency claims made by vendors of snake oil posing as useful additives, and not knowing that some additives in otherwise effective additives can actually aggravate an issue if not used correctly. A case in point is the fact that some biocides and detergents are hygroscopic, and can therefore capture and hold large quantities of water in suspension in diesel fuel.

Simply telling an irate customer who has to pay many thousands of dollars to replace a damaged injection pump that you, as a technician, have no control over the quality of diesel fuel he puts in his vehicle, is probably not wise.

However, you could use the information given above to explain that his vehicle’s general sluggishness is caused by excessive carbon deposits on the intake valves, which was in turn, caused by long-term use of substandard fuel. You could also explain that the damage to his injectors was caused by solid particulates in the fuel, and that a recurrence of the problem can largely be eliminated by installing a secondary fine-pore diesel filter with a built in water trap to remove excessive water from the fuel.

Explaining these sorts of issues and their associated costs to an upset customer is neither easy, nor pleasant. Chances are excellent that the customer simply will not believe you, given the fact that older unit injection engines never seemed to suffer any ill effects from Australian diesel fuel. This writer has had many such (difficult) conversations with irate customers, and as a result, has developed some strategies to deal with such situations more effectively. Here are some of them-

Display clogged filters

One sure-fire way to prove your point is to find a known clogged diesel fuel filter, cutting it open, and placing it in a sealed glass container to prevent the evidence messing up your counter. You may also want to cut open a new filter to illustrate the contrast between a new and a clogged filter, but generally, the sight of a clogged fuel filter is enough to persuade the customer that your point about dirty fuel may have merit, after all.

Display damaged injection equipment

If you don’t have a known damaged common rail injection pump ready at hand, you may have to spend some money to obtain one but the expense will be well worth it, since the types of damage caused by dirty fuel such as scored, excessively worn, and broken internal parts is usually clearly visible.

Showing the same types of damage on injectors is not always as easy, but a strong magnifying glass and good lighting will sometimes show signs of erosion of injection orifices, as well as scoring and excessive wear of injection needles and seats. As a rule, these types of damage to injection equipment produce poor combustion that causes power losses, rough or poor idling, misfires, poor fuel economy, and increased emissions. Therefore, if you are able to show a customer the actual cause(s) of his problem(s), that customer will be in a better position to understand the high maintenance and/or repair costs that come with modern diesel vehicles.

Display a genuinely dirty diesel fuel sample

This may be self-explanatory from your perspective, but the fact is that very few customers ever get to see the actual mass of gunk and sediment that is present in most diesel vehicles’ fuel tanks. Use a large enough sample to illustrate the point clearly, but resist the temptation to add contaminants to the sample; most customers will be horrified enough when they see what is pumped into their fuel tanks when they fill up.

Display a clogged diesel particulate filter

It has been this writer’s experience that very few owners of diesel vehicles really understand how critically important a DPF is to the emission control system on their vehicles. Therefore, when you pull out your clogged DPF, you may have to explain its function and operating principles to the customer, and this writer has found it particularly helpful to point out that a failed DPF and/or defective DEF injection system can immobilise the vehicle until the fault is corrected.

It is also helpful to point out to the customer that excessive engine idling is the single most common cause of DPF issues, since the exhaust gas never reaches the temperatures at which regeneration of the DPF can be initiated and sustained to completion. While a forced regeneration of the DPF may resolve the issue, this is not always guaranteed to work and it may in fact, destroy the DPF completely in some cases.

Keep some actual, recent third-party work orders and invoices on hand

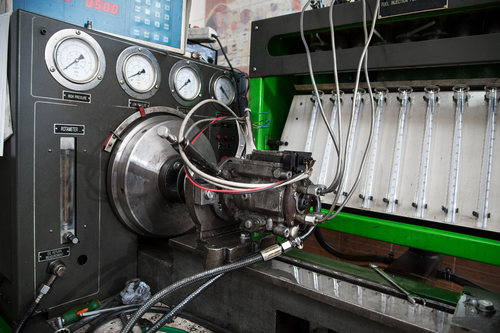

It is always worth pointing out to a difficult customer that since the testing, calibration, and rebuilding of injection pumps is a very highly specialised, and therefore, a very expensive exercise, very few workshops (dealerships included) have proper injection pump test benches.

Thus, since these procedures are generally outsourced to third party repairers, it always helps to produce recent invoices from such specialist repairers during difficult conversations with customers to show what a pump/injector test and/or recalibration procedure really costs.

The few examples of useful strategies listed here have at various times served this writer well to defuse situations where a customer refuses to believe that his hefty repair bill is an accurate reflection of the true cost of owning and maintaining a modern, high-tech diesel vehicle.

You may or may not find these measures effective in your particular situation, but what is always effective in the long run is to educate your customers as to what they can expect in terms of increased maintenance and repair costs if they skimp on the recommended and/or required servicing and maintenance of their diesel vehicles. You could perhaps mention that replacing all filters more often than the service schedule calls for, or draining the water trap(s) at least once week is whole lot cheaper than replacing an injection pump and/or a set of fuel injectors.

It is perhaps also worth mentioning that many owners of diesel vehicles tend to use too much of some diesel fuel additives too often on the grounds that twice the amount must do twice as much good, which is not only a waste of good money, but often the root cause of damage to injection equipment. Thus, educating your customers on the correct use of diesel fuel additives is particularly useful, and you can make it even more so by obtaining data sheets and relevant product information for the additives that you would recommend, and then sharing this information with your customers.