In Part 1 of this article, we looked at some of the terminology and language that BMW uses to describe some functions and processes that make their cars work. In Part 2, we will continue this discussion by focusing on some practical aspects of the language that BMW cars speak, which aspects could leave you stranded (diagnostically speaking) if you are not aware of their significance. Having said that, let us start by looking at-

It is often said that modern vehicles are unnecessarily complicated, but BMW (as do many other European carmakers) gives the term “unnecessarily complicated” an entirely new meaning. The problem is not so much that BMW and other European cars have more components or more intricate wiring than say, high-end American or Asian cars; these cars have roughly the same number of components and modules as European cars. So what’s the problem, you may ask?

You may well ask because, in the case of BMW and VAG-group cars, the problem involves the several intricate procedures one has to follow and complete successfully to make all the modules in the vehicle talk to each other in a common language. For instance, some replacement modules and components may need to be coded before they will work, while others may need to be coded and programmed, and still others, like fuel injectors, have to be “adapted” before they will work. Below is the short version of the differences between these processes, but note that none of these processes should be attempted without referring to OEM-level service information and access to factory-grade scan tools and software -

Coding (aka Encoding)

Coding a module is a relatively simple process that involves providing the module with software that will enable it to recognise the system or sub-system it will be operating in. As a practical matter, this process involves configuring the module-

Note that if the coding process does not complete successfully for any reason, the module will not accept –

Programming

BMW control modules (and many other programmable components) are typically supplied with just the software that allows it to receive the operating software of the specific vehicle it will be fitted to. It is worth pointing out that the operative words here are "specific vehicle": in practice, this means that, as a rule, previously used control modules will not work in another BMW vehicle after intallation and programming, even in cases where two BMW vehicles are identical.

It is also worth pointing out that no control module in BMW product can be programmed on its own without the scan tool interrogating all the other control modules in the vehicle on their level of programming. So in practice, programming a component like say, an ABS controller will involve the scan tool programming the controller, as well as all the other control modules in the vehicle to the same level to satisfy the demands of the I-level (Integration Level) protocols that apply to the particular vehicle, as opposed to a particular model range.

The practical upshot of the above is that programmed control modules in BMW vehicles are essentially single-use components that will only work in the vehicles they are coded to.

Adaptations

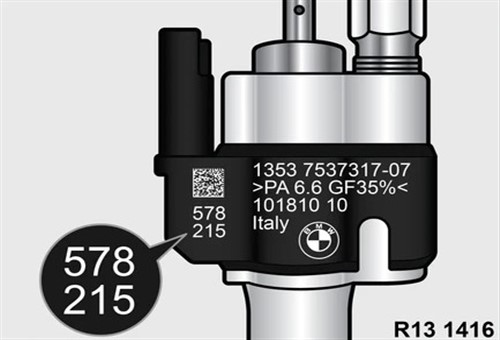

While adaptations to some systems and components on BMW vehicles are roughly analogous to the relearning procedures we often perform on non-European cars after some types of service or repairs, performing an adaptation on a BMW vehicle is generally more complicated than we are used to. Consider the image below, which shows the calibration values of a BMW fuel injector in the call-out balloon-

Image source: https://www.rpmmotorsport.net/pages/how-to-find-your-injector-serial-number

The problem with fuel injectors is that there is always a slight difference between the volume of fuel an injector should inject based on its design and tests carried out by its manufacturer, and the volume of fuel it actually injects under real-world operating conditions. This variance is caused by manufacturing tolerances and slight variations in the dimensions of any given injector’s internal components.

Thus, based on these differences, manufacturers of BMW fuel injectors calculate two calibration values for each injector, both of which are stored in the DME when it is first programmed in the factory. Moreover, the calibration values for each injector are assigned to each cylinder, so in practice, BMW fuel injectors are programmed to only work in the cylinder number they were first “assigned’ to.

More to the point, though: the DME uses the programmed calibration values to correct or compensate for the differences between the volume of fuel an injector should deliver over its entire operating range and the volume of fuel it actually delivers across its operating range. The practical effect of this correction is that all the injectors always deliver the same amount of fuel at all times, which incidentally, is the main reason why BMW engines idle and run as smoothly as they do- absent, of course, engine vacuum leaks.

As a practical matter, replacing fuel injectors on BMW and VAG-group involves using a factory-grade scan tool to remove calibration values, settings, and other stored data, and then recalibrating or adapting each replacement injector to the cylinder(s) the new injectors are installed on. Other examples of performing required an adaptation procedure could be clearing all stored data for, say the crankshaft position sensor. In this case, one needs to clear all settings, learned values, and calibration information that applies to the sensor from the DME before relearning* the sensor and DME with new basic settings.

* A form of reprogramming before the first use of the sensor.

WARNING: Note that it is imperative to verify that the scan tool or other equipment you are going to use to perform adaptations on BMW and VAG-group vehicles can complete all the required steps in an adaption procedure because if it can't, you might end up with a non-working component or even a disabled and immobilised vehicle. While such a condition can sometimes be reversed with a factory-grade scan tool and specialised software, be aware that there are no guarantees that the reversal process will always be successful.

NOTE: Be aware that some components come with theft protection activated and that only factory-grade equipment can remove this protection before programming, coding, or adaptation. Attempts to remove built-in theft protection with non-make specific equipment could potentially cause irreparable damage to the component, so be sure your equipment can remove theft protection from components before you attempt to remove it, which brings us to-

If BMW and other European vehicles speak a particular language, then DIN (Deutsches Institut für Normung) wiring diagrams represent the written form of that language, which like all languages, has its own rules and conventions.

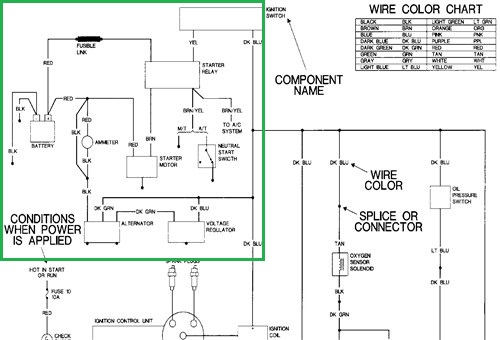

If you have never worked with DIN wiring diagrams before, you might think that these diagrams are difficult to decode or understand, but the fact is that the standards that define DIN diagrams were specifically formulated to remove guesswork and ambiguities from wiring diagrams. Unfortunately, limited space precludes a comprehensive discussion of DIN wiring diagrams here but we can do the next best thing, which is to highlight some of the principal characteristics of DIN wiring diagrams to demonstrate that DIN wiring diagrams are, in fact, easier to decode than SAE or ISO diagrams. Consider the image below-

Image source: https://www.freeautomechanic.com/wiring-digram-sample.pdf

Although the small section of a DIN wiring diagram shown here does not apply to any particular European vehicle, this diagram does include and demonstrate the basic construction that applies to all automotive DIN wiring diagrams, so let us look at how DIN wiring diagrams are constructed-

DIN diagrams can stretch over multiple to many pages, but in all cases, the source of power is always at the top of the page, meaning that power always flows down towards the bottom of the page. In the example shown here, the green square contains the wiring diagram of the charging system, but note that the source of power, which is the ignition switch, is shown at the top of the page.

Note also that, a) the components in the charging system are labelled and b) the colours of the conductors (wires) in the system are indicated by abbreviations. However, in some cases, the abbreviations and component labels will be for German words but in such cases, the DIN standards demand that the4 diagram includes a table or legend that provides the English versions of German words and phrases, as in the example shown here.

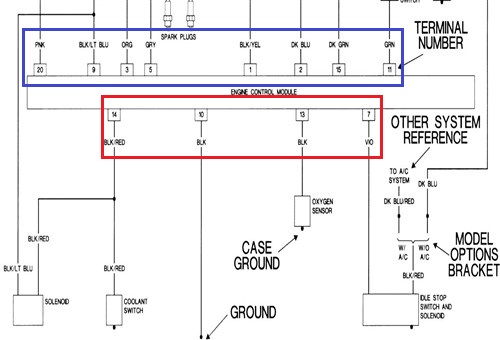

Moreover, as shown here, lines that represent circuits mainly run vertically down the page. These lines are numbered and known as “tracks” that may or may not extend to the next page, so consider the image below-

Image source: https://www.freeautomechanic.com/wiring-digram-sample.pdf

This image, which is a part of the same example DIN wiring diagram shown earlier, shows that numbered tracks do not terminate at the bottom of the page but at the input side of the engine control unit, as shown in the blue box.

The output side of the engine control unit is represented by the red box, and the numbered tracks that exit the engine control unit all terminate in electrical consumers, except for track 10, which terminates in a chassis ground connection. In cases where the tracks run down to the bottom of the page, each track will be numbered on both pages to make it easy to find a track/circuit that continues on the next page.

As a practical matter, all DIN wiring diagrams for all European vehicles are constructed in the same way (as shown above) and although all DIN wiring diagrams contain valuable information in the form of tables, legends, and lists of abbreviations that identify components, it would be a mistake to underestimate the complexity of some DIN diagrams.

The above is especially true of high-end BMW vehicles that have a multitude of bells and whistles as standard equipment, so, if you are not fluent in BMW-speak, we strongly recommend that you visit this resource, which is a comprehensive tutorial written in plain language to learn the finer nuances of the language that BMW (and other European vehicles) speak, which leaves us with this-

Working on BMW and other European vehicles can be challenging if you don’t understand the language they speak. However, on the upside, it is also true that acquiring this language will not only improve your diagnostic skills; it will also equip you with the knowledge to compete for better job opportunities in the high(er) end of the independent car repair industry, which, we can all agree, can never be a bad thing.