In Part 1 of this series of two articles, we discussed some of the things we in the independent repair industry can do to repair, service, and maintain the systems and components that hybrids and electric vehicles have in common with conventional vehicles. In Part 1, we covered hybrid engines and more specifically, their cooling systems as well as brake systems in some detail, and in Part 2, we will discuss battery service/maintenance, wheel and tyre service, and more. Let us start with-

Image source: https://injectronics.com.au/assets/Uploads/Injectronics-4-v2.jpg

It is certainly possible for independent workshops to remove and even fit HV battery packs in hybrid and electric vehicles. However, we do NOT recommend that anybody attempt this procedure without having (at a minimum) access to dealer-level service information for the specific vehicle, as well as proper and approved safety equipment, rated tools, and the training required to complete these procedures safely.

Although a detailed discussion of HV battery pack removal, testing, and installation procedures falls outside the scope of this article, we can say this: getting some of the steps wrong or failing to follow the prescribed steps in the correct order can not only destroy the battery pack or set the vehicle on fire, it can also cause fatal electrocution. Simply do not touch HV battery packs if you do not have the training and equipment to do so safely.

Nonetheless, one of the biggest reasons why so many independent workshops turn away hybrid vehicles with battery issues is that while training, tools, and safety equipment are all relatively cheap to acquire, the equipment required to test, assess, and remanufacture hybrid battery pack is not, because this type of equipment is prohibitively expensive, and out of reach for most independent workshops.

Assuming for the moment, though, that you diagnose serious issues with a hybrid battery pack and have what you need to remove it from the vehicle safely, what do you do with it if you can’t repair it yourself? You could replace it with a new battery, but that may be prohibitively expensive for your customer, so the better option is to ship the battery to Injectronics, the only hybrid battery remanufacturer that is fully supported by the Federal Government. Injectronics will send you a fully remanufactured battery pack and they will swap with a warranty backed high quality remanufactured battery specific for your make / model. The returned battery unit will undergo assessment for remanufacturing consideration and quality testing and if meets criteria, will be made available for the next customer.

Injectronics also operate many sites across the country, so you can have your customer’s vehicle back on the road in (almost) no time, and at cost savings of between 30 and 40 per cent compared to the price of a new battery pack. Note though that while Injectronics currently offers this service only for a limited number of models, you can contact them here for details on locations and other services offered, which brings us to-

12V battery maintenance and service

If you have never worked on hybrid and/or electric vehicles before, you may find it somewhat surprising that these vehicles also have 12V batteries that supply power to all the systems and components that 12V LSI batteries in conventional vehicles supply. However, there are some notable differences in how these batteries are integrated into the electrical systems of hybrid and electric vehicles. Here are some details to keep in mind-

As a practical matter, though, the most important thing to remember with 12V batteries in hybrid and electric vehicles is that these batteries should always be replaced by batteries of the same type, construction, and ratings. In all cases, the replacement battery must be identical to the original battery in all respects, and getting this wrong could cause extensive damage to the vehicle's electrical system. So, now that you know what to expect with battery maintenance, let us look at what we can do on-

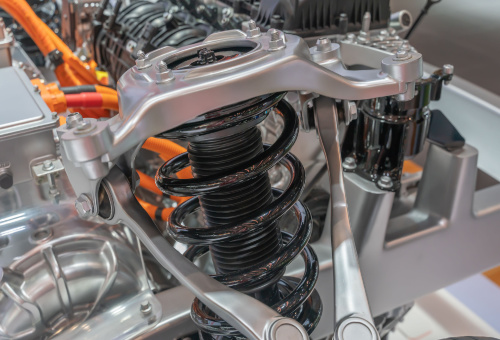

At first glance, it might appear that there are no meaningful differences between the suspension systems on hybrid and electric vehicles and those on conventional vehicles. After all, all hybrid and electric vehicles have shock absorbers, springs of various types, control arms, and other suspension parts we see on conventional vehicles every day.

In practice, though, there are often major differences between the geometries of the suspension systems of hybrids/electric vehicle vehicles and the suspension systems of conventional vehicles. The reason for this is that both hybrids and electric vehicles are not only significantly heavier than directly comparable conventional vehicles, but also the distribution of weight between the front and rear axles is different because most of the weight of HV battery packs is typically at, or near the centre of a hybrid or electric vehicle.

This is an important point for two reasons. The first is that while the shock absorbers and springs on hybrid and electric vehicles often appear identical to shock absorbers and springs on conventional vehicles, the shock absorbers and springs on hybrid and electric vehicles have greatly different compression and rebound rates to cope with the weight of the HV battery pack. The second reason is that the (sometimes significant) differences between the suspensions of hybrid and electric vehicles and those of conventional vehicles are not so great that we in the independent repair industry cannot service, repair, and maintain these systems safely and profitably.

As a matter of fact, there is nothing about hybrid and electric vehicles’ suspension systems that prevent independent workshops from replacing parts and components like-

- and others, such as airbags and compressors on vehicles with air suspensions. The only caveat is that since many of these parts sometimes appear identical to similar parts for conventional vehicles, these parts and components must be indicated for use on hybrid and electrical vehicles. Put differently, this means that even though a part like a control arm might appear to be similar to a control arm for a similar or related convention vehicle, the control arm for the hybrid or electric vehicle might have slightly different angles and distances between mounting points.

So, while there is nothing to prevent an independent workshop from replacing suspension parts on hybrid and electric vehicles, extreme care must be taken to ensure that the correct parts are fitted to the vehicle to maintain the suspension systems’ geometry. Also, some suspension repairs require the recalibration of one or more ADAS systems, including recalibrating the steering angle sensor during subsequent-

In terms of design and operating principles, there are no meaningful differences between the steering systems of hybrid and electric vehicles and the steering systems of conventional vehicles. Like the steering systems on conventional vehicles, hybrid and electric vehicles use identical, or directly comparable steering gear, and all the other parts required to make the steering system work.

Thus, there is no reason why independent workshops should not be able to service, maintain, and repair the steering systems on hybrid and electric vehicles, including recalibrating steering angle sensors.

As with steering systems, there are no significant differences between the drive shafts of hybrid and electric vehicles and the drive shafts on conventional vehicles. The only possible exception to this rule of thumb is that the CV joints on electric vehicles are often somewhat heavier and sturdier than CV joints on comparable conventional vehicles, to cope with what are essentially shock loads when all the torque of an electric motor is transferred almost instantaneously to the drive wheels.

Ultimately, though, the CV joints on electric vehicles are just CV joints that work and fail in the same ways as CV joints on conventional vehicles. Therefore, the service, repair, and replacement procedures of CV joints on electric vehicles are largely similar, if not always identical to the procedures that apply to conventional vehicles. Note, though, that you may require special pliers or other tools to remove the CV joints from the drive shafts of some electric vehicles.

The exhaust system on all hybrid vehicles performs the same function as it does on a conventional vehicle. Moreover, hybrid exhaust systems are made up of the same parts, including silencers/mufflers, catalytic converters, oxygen sensors, as well other sensors such as NOx sensors, exhaust backpressure sensors, and exhaust gas temperature sensors that make an exhaust system work on a conventional vehicle.

Of course, not all hybrid exhaust systems contain all of the sensors mentioned above, but in terms of practicalities, servicing, repairing, and/or replacing the exhaust system on a hybrid vehicle is, for the most part, identical to servicing, repairing, or replacing an exhaust system on a conventional vehicle. This means that any independent workshop or fitment centre will be able to service, repair, or replace hybrid vehicles' exhaust systems without encountering difficulties, with the only possible exception to this being the availability of some parts in remote locations.

Aligning the wheels on a hybrid or electric vehicle is largely similar to aligning the wheels on a conventional vehicle. However, there is one notable difference, which is the fact that wheel alignment settings on especially electric cars generally do not allow for the same relatively large tolerances and deviations from specified values that we see in the settings for conventional cars.

The principal reason for this is that any additional rolling resistance caused by poorly aligned wheels on hybrid and electric cars is that it decreases an electric vehicle’s useful range, and increases fuel consumption on hybrid vehicles.

So, while there are no good reasons why any competent independent workshop can’t perform wheel alignments on both hybrids and electric vehicles, the guiding principle during the procedure must always be that “Close Enough is Never Good Enough”. Always try to achieve the factory specifications exactly: if you can’t, keep deviations from specified settings within acceptable and allowable limits, just as you would on a conventional vehicle, which brings us to-

If your workshop does tyre service and replacement, including wheel/tyre balancing on conventional vehicles, there is no good reason why you should not also perform the same services on hybrid and electric vehicles. However, tyres for use on hybrids and electric vehicles differ from those of conventional tyres in major and meaningful ways: in fact, engineers consider more than 200 variables when they design new e-tyres to ensure a balance between cost, performance, safety, and durability in all driving conditions.

Below are some details on how tyres intended for use on hybrid and electric vehicles differ from tyres used on conventional vehicles-

E- tyres are more rigid

Since hybrid and electric vehicles are significantly heavier than directly comparable convention vehicles, e-tyres have hugely reinforced sidewalls to reduce flexing of the tyre under the weight of the vehicle.

E-tyres can cope with higher power outputs

Since the torque of an electric vehicle's electric motors is instantly available, the combination of stronger sidewalls, advanced rubber compounds, and computer-designed tread patterns allow e-tyres to absorb extremely high torque loads without excessive deformation of the tyres occurring.

E-tyres have a lower rolling resistance

Since rolling resistance has a direct bearing on an electric vehicle's useful range and a negative effect on a hybrid vehicle’s fuel consumption, e-tyres are designed to have an exceptionally low rolling resistance, provided they are inflated correctly, and that all wheel alignment settings are within OEM specifications.

E-tyres are quieter than conventional tyres

Because electric vehicles only emit a low, and sometimes hard-to-detect humming sound, e-tyres are designed to run extremely quietly to reduce or eliminate tyre noise at moderate to high road speeds. As a practical matter, fitting even the most advanced conventional tyres to an electric vehicle will cause so much road noise that normal conversation inside the vehicle would be difficult, if not always impossible.

So, if you keep the above four points in mind, there is nothing that prevents independent tyre service centres and workshops from performing tyre and wheel services on hybrid and electric vehicles, using the same equipment, procedures, and attention to detail that applies to conventional tyres and vehicles, which brings us to-

Using the OEM-recommended fluids and filters in hybrid and electric vehicles is just as important as it is in conventional vehicles. For instance, the internal combustion engines in hybrid vehicles require regular air, fuel, and oil filters on more or less the same service/replacement schedule as most conventional vehicles. In practice, replacing these filters, including the cabin air filter, on a hybrid vehicle is no more complicated than replacing filters on a conventional vehicle, so most independent workshops should have no problems with doing regular and/or routine servicing on the engines in hybrid vehicles.

However, there is somewhat of a downside to filter replacements on hybrid vehicles, and it is the fact that sometimes, some filters are not freely available, especially in remote areas. Although this can sometimes present problems and cause delays in returning a vehicle to a customer, Ryco filters are always available from a network of authorized distributors. Moreover, Ryco filters are engineered to meet, and often exceed OEM products in terms of fit, form, and function, so it makes sense to use filters whose performance is guaranteed.

Other regular checks and services we can do on hybrids include checking brake fluid levels and testing brake fluid for contamination with copper and other substances. Note, though, that while it is possible to replace contaminated or degraded brake fluid on hybrid vehicles, this should only be done strictly according to OEM-service procedures, for which you may require special software and a suitable scan tool. Of course, this is no hardship, since we perform similar procedures on conventional vehicles all the time, meaning that there is no reason why independent repair workshops can’t do it on hybrid vehicles, or on electric vehicles, for that matter, which brings us to-

EV coolants

Electric vehicles, on the other hand, require a somewhat more focused approach with regard to coolants. As mentioned elsewhere, Castrol has developed an extensive range of coolants, lubricants, and greases specifically for use on electric vehicles. This is an important point since many electric vehicles use different coolant types and/or coolant formulations in different parts of the HV cooling system. Of course, we are not suggesting that you should start replacing the coolants in HV systems, but we are suggesting that should you need to replace any coolant on an electric vehicle, you can find technical details, specifications, and recommended applications of all Castrol’s e-fluids here, to make sure you use the correct coolant.

Take note, though, that while it is entirely possible for independent workshops to replace coolants in electric vehicles, these procedures are somewhat complicated, as well as make and model specific. So before you attempt this procedure, be sure to have access to reliable and up-to-date service information to ensure that all air is purged from the affected system(s).

In terms of design and operation, there are no meaningful differences between the wiper systems of hybrid and electric vehicles, and the wiper systems of conventional vehicles- with one exception that involves some Tesla models. On these models, you have to place the wiper system in Service Mode via the touch screen in the dashboard to gain access to the wipers if you want to replace the blades.

That said, there is not much to say about wiper blade replacements on hybrid and electric vehicles except that a) the actual replacement procedure is the same as on conventional vehicles, and b) that if you are going to replace the wiper blades, it makes good sense to replace worn blades with Trico wiper blades.

Why Trico blades? There are many reasons why Trico wiper blades should be our first choice in replacement wiper blades, not the least of which is the fact that Trico offers a wide range of designs, types, and exact-fit replacement wiper blades for almost any vehicle on Australia’s roads today.

More to the point, though, what you replace your customers’ wiper blades with forms a large part of how customers perceive the service they'd received from any service provider. Therefore, fitting high-quality wiper blades that work as your customer would expect them to every time the wipers are switched on will go a long way towards increasing customer satisfaction and retaining existing customers, which leaves us with this-

We hope that this series of articles has given you some new insights into how similar hybrid and electric vehicles are to conventional vehicles, as opposed to how different they are. By focusing on the similarities, rather than on the differences, we can service, repair, and maintain (almost) every system, part, and component on our customers’ hybrid and electric vehicles, and without the need to touch HV systems and battery packs, at that.

Given the above, there is no reason why any mechanical work on hybrid and/or electric vehicles should be turned away, simply because these vehicles fall somewhat out of comfort zones. In fact, with the fairly rapid rise in hybrid and electric vehicle sales, many independent workshops will soon have no choice other than to accept this type of work, so we all might as well get to know these vehicles sooner rather than later.