There is no doubt that the global climate is changing for the worse, and while the automotive manufacturing industry is not the biggest contributor to climate change, this industry and its roughly 1.4 billion products in use today have, and continue to have huge negative impacts on the global environment.

Therefore, the need to find and develop zero-emissions alternatives to fossil fuels has become a top priority for environmental protection agencies across the globe, but while several promising candidate fuels, including hydrogen, are currently being evaluated, we are a long way from having a zero-emission fuel available in commercially viable quantities on a global scale.

In this article, we will take a closer look at hydrogen as a possible replacement for fossil fuels both in terms of it works in automotive applications, and why it is not in use already given that hydrogen is the most abundant element on Earth. However, before we get to specifics, let us look at some key findings in a recent report published by the European Commission-

NOTE: While the findings contained in this report apply to the European automotive market, there is no reason to believe that these findings do not also apply to other markets, and especially to markets that do not require legally mandated periodic emissions testing of vehicles. Nonetheless, some of the report’s key findings are reproduced below-

Section 1: Transport is Europe’s biggest source of CO2, responsible for the emission of over a quarter of all greenhouse gases. Transport emissions have increased by a quarter since 1990 and are continuing to rise with 2017 oil consumption in the EU increasing at its fastest pace since 2001. (Italics and bolding added for emphasis)

Section 2: To date measures to tackle emissions from cars and vans have largely been a failure. New car CO2 regulations have delivered only about a 10% reduction in on-road emissions in the 20 years since the first Voluntary Agreement was established in 1998 [and] there has been effectively no improvement in the last five years. Despite this, all carmakers achieved their 2015 new car CO2 targets and most are on track to achieve 2020/1 goals. This has been achieved in very large part by exploiting the flexibilities in the testing procedure, which has meant the gap between test results, and real-world performance has grown from 9% to 42%, equivalent to 31gCO2/km of fake savings.(Italics and bolding added for emphasis)

Section 7(b): The car industry circumvents emissions regulations by all possible means – and has successfully done so for decades. Despite the Dieselgate scandal and the exposure of CO2 testing manipulation, new evidence is emerging of ways to manipulate the results of the new Worldwide-harmonised Light vehicles Test Procedure (WLTP). Emerging evidence suggests carmakers are inflating WLTP values whilst keeping [the] New European Driving Cycle (NEDC) values low. This would help them maximise test flexibilities for the NEDC-based 2021 CO2 target whilst simultaneously inflating the WLTP 2021 starting point for the 2025 and 2030 regulation. In addition, the industry consistently fits technology to cars that will deflate emissions far more in the lab than on the road, such as short-range plug-in hybrids, stop-start and cylinder deactivation. (Italics and bolding added for emphasis)

The report has much else to say besides, but these excerpts from the report should make it abundantly clear that the automotive industry is highly resistant to a), the adoption of meaningful strategies to combat exhaust emissions, and b), the idea of investigating and adopting zero-emission fuels.

However, despite the demonstrable resistance of car manufacturers to do something tangible about the negative effects their products have on the global climate, some manufacturers including Honda, Hyundai, and Toyota are currently actively researching, constructing, and marketing vehicles that use hydrogen as a primary energy source. While it is not for this writer to pronounce an opinion on these manufacturer’s motives, the fact is that Toyota is currently marketing a hydrogen-fuelled vehicle in the US market (albeit in very limited numbers) so let us look at how Toyota has managed to make hydrogen work as an automotive fuel. Let us start with a look at the heart of the propulsion system, known as a-

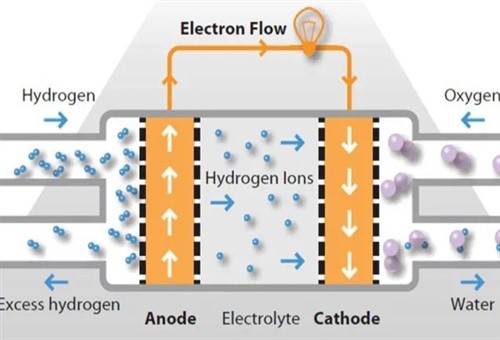

Image source: https://www.igem.org.uk/

This image is a somewhat simplified schematic diagram of a typical hydrogen fuel cell and it shows both the principal components and the basic chemical reaction between hydrogen and oxygen that produces an electrical current. We need not delve into the complexities of this chemical reaction here, beyond saying that the only waste products of the process are water vapour and a little waste heat.

Essentially, the fuel cell replaces the internal combustion engine, thereby effectively creating a fully electric vehicle. However, to understand how this works we need to discuss the basic operating principles of hydrogen fuel cells (if not the chemistry involved) but since we are not likely to see hydrogen-fuelled vehicles in our bays any time soon we will keep things relatively simple, so here is how it works-

In its simplest form, a hydrogen fuel cell is roughly analogous to a conventional battery, but unlike batteries that contain the chemicals they need to work, a hydrogen fuel cell has to be continually supplied with pressurised hydrogen from an onboard storage tank, and oxygen from ambient atmospheric air.

As a practical matter, however, a hydrogen fuel cell's operation depends on two fundamental, but simple scientific principles. The first is that positive and negative electrical charges attract each other, and the second is that a hydrogen atom consists of one positively charged proton and one negatively charged electron.

In terms of its construction, a hydrogen fuel cell contains a kind of electrolyte that is clamped between an anode and a cathode, which act as positive and negative terminals, respectively. When the system is activated, pressurised hydrogen gas is exposed to the anode, while oxygen is exposed to the cathode. Since the positively charged anode acts as a catalyst, the hydrogen atoms are broken up into electrons with negative charges, and hydrogen ions* with positive charges.

* Strictly defined, an ion, in this case, a hydrogen ion, is the nucleus of a hydrogen atom that had been separated from its accompanying electron, hence its positive electrical charge.

During operation, the electrolyte acts a kind of filter that only allows the positively charged ions through to reach the cathode, in much the same way that diodes allow an alternating current to flow through it in only one direction. Since the negatively charged electrons cannot pass through the electrolyte "filter", they flow towards the cathode via an “outer circuit”, and it is this flow of electrons that constitutes the electric current.

However, electrons that flow towards the cathode via the outer circuit eventually encounter the ions that passed through the electrolyte filter on their way to the cathode. When they meet, they recombine to form complete hydrogen atoms, which then combine with excess oxygen atoms to form water molecules as the only waste product (apart from a little heat) of the electricity generation process.

In practice, though, the energy yield from the small fuel cells that fit inside cars is too low to drive an electric motor directly, even though Toyota claims that the fuel cell in the second-generation, 2020 Toyota Mirai has a power output that is equivalent to about 100 kilowatts. Therefore, hydrogen-fuelled cars need other components besides a fuel cell to make them work, so let's look at these components, starting with-

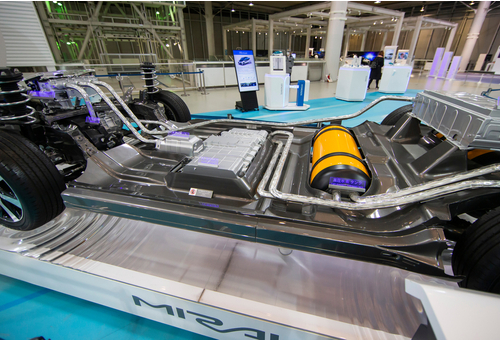

Like conventional electric vehicles, a high voltage battery pack is required to run the electric motor over extended periods. In the image above, the primary high-voltage battery is in the middle of the floor pan of this cut-away version of a Toyota Mirai chassis.

Toyota has drawn heavily on the experience it has gained with HV battery packs that were developed for their highly successful Prius model range, and like Prius batteries, the batteries in hydrogen-fuelled cars are made up of cells that are connected in series to produce a nominal voltage of several hundred volts. However, unlike Prius batteries, the batteries in Toyota Mirai models are of the nickel-metal hydride variety, and they boast a power output of 21 kilowatts.

A secondary battery, which is roughly analogous to the 12-volt battery in hybrid vehicles, is used to power low-voltage accessories, as well for storage of electricity generated during regenerative braking. The secondary battery also supplies additional power to the electric motor during hard acceleration.

The yellow cylinder in the image at the top of the previous section is the storage cylinder for pressurised hydrogen gas*. In this example, the cylinder can hold sufficient hydrogen gas at a pressure of 70 MPa to provide a driving range of about 480 km in a mix of city and highway driving.

* While liquid hydrogen will provide a vastly extended driving range, the equipment required to keep the hydrogen in a liquid state is too bulky and energy-intensive to fit into a passenger vehicle.

As with the HV battery, Toyota has drawn heavily on the design of the electric motor used in its hybrid vehicles. Therefore, the electric motor in the hydrogen-fuelled Mirai is also a synchronous, three-phase AC unit that does double duty as a generator during regenerative braking. In terms of practicalities, this motor develops 90 kW of power and 260 Nm of torque, which provides performance that is comparable to that of similar electric and hybrid vehicles.

The power control unit is similar in design and operation than power units in use on Toyota hybrid vehicles, in the sense that it converts DC into AC and functions as a DC-to-DC converter to charge the secondary battery. However, in the hydrogen-fuelled Mirai, the power control unit incorporates a purpose-built "power booster", which is essentially a step-up transformer that increases the total power output of the power control unit. This development of this transformer allowed designers to reduce the size and weight of the fuel cell, HV battery, and electric motor to reduce the overall weight of the vehicle.

As shown in this image, refuelling a hydrogen-fuelled Toyota is as easy as connecting a hose to the fitting that takes the place of the filler pipe on a conventional liquid-fuelled vehicle. Refuelling generally takes between three and five minutes, which compares favourably with the time needed to refuel a conventional vehicle.

So, given that hydrogen produces no harmful exhaust emissions, and that the technology is known to be safe, reliable, and based on proven componentry, one particular question comes to mind- this question being-

As matters stand now, there are several very good reasons why hydrogen has not seen much uptake in automotive markets, and especially in the Australian market. One reason involves the car manufacturing industry’s vested interests in the oil industry- as the report cited at the top of this article points out.

Another reason is more practical, and it involves the lack of a distribution network to bring hydrogen fuel to consumers. For instance, even though the Federal Government has officially certified the 2019/2020 hydrogen-fuelled Hyundai Nexo as suitable for use on Australia's roads, there is only one active hydrogen fuelling station in Australia. This facility is located behind Hyundai's Head Office building in Sydney, and it is used exclusively by Hyundai.

Other stations are in various stages of completion in Canberra and Melbourne. However, these stations are also reserved for Hyundai's exclusive use, although a commercial hydrogen fuelling station is under construction to serve the greater Sydney metropolitan area- with completion expected in about two years.

Other refuelling locations under consideration and/or construction include one in Brisbane to serve a small fleet of Hyundai Nexo vehicles belonging to the Queensland Government, and another in the Australian Capital Territory to serve a fleet of about 20 Nexo vehicles that will belong to that Government.

By way of contrast, the only refuelling facility Toyota can offer is currently on the back of a truck, which services its small fleet of hydrogen-fuelled test vehicles in various locations around the country. However, Toyota is engaged in a joint venture with the Victorian Government to establish a commercial hydrogen refuelling station in Melbourne.

While the lack of a distribution network is arguably the biggest problem to overcome before hydrogen will experience a significant uptake in the market, there are two more factors to consider, both of which will likely contribute to significant consumer resistance against hydrogen-fuelled vehicles. Let us look at these issues, starting with-

Although the Hyundai Nexo has been available in Australia since 2019, it is not clear what its asking price will be once it becomes widely available to the public. However, one authoritative source states that it might be as high as $85 000, which would buy a high-end BMW, such as an X5.

There is also no information available on yearly running and maintenance costs, especially concerning fuel and servicing costs- if one can find fuel for it, in the first place.

According to research by the US Department of Energy, hydrogen fuel cells in automotive applications are unlikely to last for longer than about 120 000 km, which is significantly shorter than any other automotive power source, including HV battery packs in hybrid and electric vehicles.

At issue is the fact that free radicals in hydrogen peroxide that forms during the electricity generation process attacks various internal parts and surfaces of the fuel cell, causing progressive deterioration and degradation of the fuel cell as a whole. Since there is no information available on either replacement costs or replacement procedures from any manufacturer of fuel cells, the questionable durability and reliability of hydrogen fuel cells will remain a significant obstacle in any future development of hydrogen as a viable alternative to fossil fuels, which leaves us with this-

As matters stand now, it is difficult to see how hydrogen would replace fossil fuels in the short to medium term, despite the obvious advantages that hydrogen offers in terms of exhaust emissions.

However, if one considers the facts that, a) making a hydrogen-fuelled car creates almost as much pollution as making a conventional vehicle does, and b), that crude oil is still relatively plentiful as well as cheap to extract and refine, it becomes easy to understand why car manufacturers and the oil industry have no real incentive(s) to develop zero-emission fuels.