According to all accounts, draft legislation that will describe the details of the Mandatory Data Sharing scheme will be submitted to Parliament in a matter of weeks, as opposed to months. While nobody is quite sure what this draft legislation will include, the fact that this matter is now finally coming to a head is good news for Australia's independent workshops.

Moreover, and also according to all accounts, the draft legislation will not be subjected to a lengthy consultation process, since much, if not all of the required consultations have already taken place over the past decade or so. Therefore, the Mandatory Data Sharing scheme could become law sooner rather than later, and when it does, we, as technicians, need to be ready and able to perform diagnostics at much higher levels than we have become used to. Thus, in this article, we will take a close look at how we can expect diagnostics to change for the independent repair industry, but with a special focus on the hardware and equipment you will need to perform effective diagnostics on new vehicles. Let us start with this question-

This question has several possible answers, including "No", "Yes", and "Maybe", depending on your current experience and skill levels. This might sound somewhat confusing, but since this writer does have some years of dealer-level diagnostics to his credit, we can explain each possible answer somewhat more clearly based on his experience. Let us start with-

In its purest form, automotive diagnostics in an independent workshop does not differ greatly from automotive diagnostics in a dealer workshop. You still need to have a clear understanding of the problem, you still need to be able to replicate the problem, and you still need to develop a rational and logical diagnostic strategy to diagnose and resolve the issue.

If you are reasonably proficient in doing the above on 10-year-old vehicles, the transition to dealership-level diagnostics should not be too difficult, although learning the operating principles of systems and scan tools that we currently do not have access to could be a very a steep learning curve. Therefore, the "No" option is a qualified option because we could be in situations where we might not know what we don't know when we encounter some kinds of problems on new vehicles.

One example that comes to mind involves issues in telematics systems. These systems connect a vehicle to the outside world via various internet communications protocols, and in practice, there is often a significant amount of overlap, or integration between telematics systems, security/anti-theft systems, and some ADAS systems in some of the latest vehicles. Therefore, diagnosing issues in these types of systems requires factory-level scan tools and software that can only be obtained from the vehicle manufacturer.

In practice, some types of problems in ADAS/telematics/anti-theft systems can only be diagnosed and resolved by linking a scan tool to a remote technical support centre operated by the vehicle manufacturer, which means that in some cases, what you thought you knew about diagnostics won't be enough to diagnose some issues.

While the high-end generic scan tools we use daily do pretty decent jobs of diagnosing most kinds of issues on most vehicles, the kind of scan tools we will require when we have full access to service and repair information do several things differently to what we have become used to.

For instance, while most high-end generic scan tools can reprogram keys, calibrate steering angle sensors, perform most relearning procedures, and even reprogram a limited number of control modules, the tools we know typically do not have the level of bi-directional control capabilities that factory scan tools have.

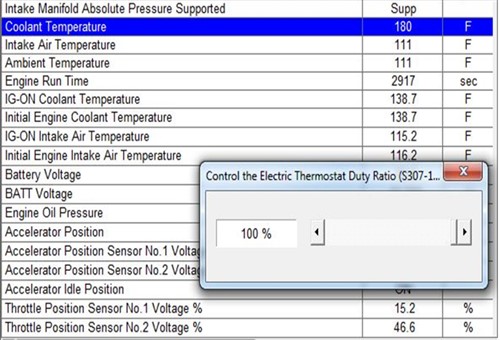

The ability to activate actuators and simulate sensor outputs is arguably the single most valuable diagnostic aid we can ever have, and to get an idea of what factory scan tools are capable of, consider the two partial screenshots taken from the display of a Toyota TechStream scan tool shown below-

Image source: https://www.searchautoparts.com/sites/default/files/images/MA1220-D-3.png

In this screenshot, checking the coolant temperature is selected and the actual coolant temperature is displayed. The smaller pop-up window allows the user to control the duty cycle of the electrically controlled thermostat, and in this case, the thermostat is set to fully open. However, the next screenshot shows just how specialised Toyota's TechStream scan tools are-

Image source:https://www.searchautoparts.com/sites/default/files/images/MA1220-D-3.png

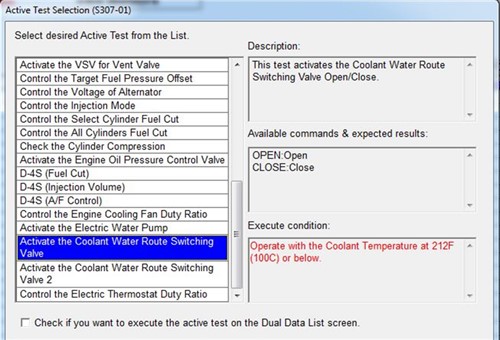

In this screenshot, that shows a small fraction of the available-directional controls that are available for the vehicle under investigation, the option to control the coolant flow control valve is selected, which is not possible to do with any generic scan tool that this writer is aware of. Nonetheless, while car manufacturers will be legally obliged to make this software available to independent workshops under the Mandatory Data Sharing scheme, the scheme will almost certainly not oblige car manufacturers to make this software and service information available free of charge. For instance, in the US market, Toyota makes this information available to independent repairers under the TIS Professional Level protocol at a subscription charge of $65 for two days' access.

As a practical matter, subscribing involves registering at nastf.org (which requires paying an additional fee), and undergoing a thorough background check if you need information relating to any vehicle's security codes/information to diagnose immobiliser and/or smart keys issues.

Nonetheless, the single most important skill to learn about OEM-level diagnostics is learning to ask the tool the right questions, because factory scan tools are not yet so perfect that they will spell out the cause(s) of a problem for you. Even so, factory scan tools have so many capabilities and functions that vastly exceed those of even the best high-end generic scan tools that the question becomes not so much one of how to diagnose the vehicle, but how to find, and use the relevant options on an advanced scan tool to best effect to make a diagnosis.

The above is just one example of how advanced factory-level scan tools are, but for all that, these tools suffer from one major drawback, and that is their eye-watering cost. Most factory scan tools have prices that range between $8 000 and about $10 000, and that usually does not include software subscriptions, which makes buying a scan tool for each vehicle brand a prohibitively expensive exercise.

Consider this; when Right to Repair legislation was enacted in parts of the USA in 2012/13, independent workshops in that market had to purchase, at a minimum, hardware, and software for-

These were the minimum requirements just to service/diagnose/repair some of the major brands, and many independent workshops were forced to take on significant debt to finance this equipment. However, continued pressure on regulatory authorities by the independent repair industry in the US market led to the development and approval of devices that eventually obviated the need to buy a dedicated scan tool for each brand of vehicle, so let us look at-

Also known as J2534 devices, or simply as J-boxes for short, pass-through devices can perhaps be described as a one-size-fits-all approach to communications between vehicles and scan tools. In practice, J-boxes are interfaces that fit between a vehicles' serial communications system, and a laptop computer, with the interface having the ability to "translate" the sometimes-manufacturer specific communications protocols and standards in use on a given vehicle into a language that is compatible with the diagnostic software on the laptop computer.

Put differently, this arrangement means that the diagnostic information extracted from a vehicle passes through the interface into the laptop, where the computer's operating system does the actual computing, such as generating a graph of the throttle position sensor's output voltage, as opposed to the computing happening in a dedicated brand-specific scan tool.

It is perhaps worth noting though that although the J2534 standard was developed by the SAE (Society of Automotive Engineers) to create an Application Programming Interface that would apply to all vehicle manufacturers without the need to use a factory scan tool, this only applied to vehicles that were made and sold in the US market. However, this part of the J2543 standard is especially noteworthy-

"J2534 pass-thru reprogramming is only required for emissions based ECUs (eg. Powertrain, Engine, Transmission, Throttle Controller) and is mandatory on all vehicles from the 2004 model year and onwards. Additional support of reprogramming Chassis and Body ECUs will be dependent on each manufacturer's (sometimes proprietary) reprogramming application software capabilities. (Source: https://www.boschdiagnostics.com/j2534-faq)

For our purposes, the part about "additional support" is particularly important because for some programming functions on vehicles that were made before 2018 we still need a factory scan tool to program some control modules. These modules typically relate to ADAS and advanced telematics systems, but in a few cases, more mundane body and/or chassis related control modules can't be reprogrammed with a J-box.

However, the latest revisions to the J2534 standard, and particularly the SAE J2534-2 standard, now make it possible to program almost all control modules (including non-emissions related modules) on almost all vehicles made after 2018, which means that the need to have factory scan tools available is reduced even further. As a practical matter, therefore, when the Mandatory Data sharing scheme is enacted it will be possible for technicians in independent workshops to do about 98% of the diagnostics and reprogramming that dealership workshops do on new vehicles.

Before you get too excited at the prospect of being able to do what dealerships do in terms of diagnostics and programming, bear in mind that you need yet another piece of hardware, and this one is perhaps the most critically important link in the chain, so let us look at-

Image source:https://www.searchautoparts.com/sites/default/files/images/MA1220-D-6.png

While it is possible to use a desktop PC and separate monitor mounted on a cart or trolley, this option is not only cumbersome, it is also a good way to destroy a computer or monitor when it is knocked off the trolley.

Therefore, while laptops are not immune to damage, we recommend using laptop computers because they are easier to handle in confined spaces such as engine compartments. However, the computing and RAM requirements of dealer-level diagnostic software are such that you can't just use any old laptop(s) you have lying about, so below is what this writer has found works best in terms of the properties and features an ideal laptop should have-

Laptops should ideally be new, and suitable for "rough service conditions"

While it is possible to use a reasonably new laptop, the advantage of a new computer is that it is "uncontaminated", in the sense that it does not contain traces of deleted software, pictures, movies, games, and other data. Bear in mind that when anything is deleted from a hard drive, the deleted material is not physically removed from the hard drive: sectors on the hard drive marked for deletion are kind of sign-posted by the operating system, and those sections are then made available to be written on again.

This also happens when a computer running Windows 10 is reset through the "reset" function. While personal settings may be reset to their default values, all the data and installed software that was on the hard drive remains on the hard drive even after the reset procedure, and can be recovered with specialised software after the reset procedure, but why is this important?

It is important because diagnostic software typically requires "clean install conditions" to prevent conflicts with previously deleted data. These kinds of conflicts are arguably the biggest single cause of diagnostic software crashes and failures, so if you can't afford a new laptop computer, be at least sure to replace the hard drive* to ensure that your diagnostic software is installed into a "sterile" environment.

*While it is possible to use old-style rotary hard drives for diagnostics, the latest trend has been to use solid-state hard drives that have no moving parts. This does not only ensure longer component life but since solid-state hard drives are essentially microprocessors, both boot times and processing speeds are greatly increased, as well.

Make sure you have sufficient RAM

All dealer-level diagnostic software suites are extremely RAM intensive, and as a result, all such suites require a minimum of 8GB of RAM to run smoothly but note that the required RAM does not include virtual memory, which is a variable value that is constantly adjusted by the operating system to prevent system freezes and crashes.

Therefore, we recommend that you take sufficient time to study the system requirements prescribed by the publishers of diagnostic software to prevent extremely annoying system crashes when you are running, for instance, graphing, or oscilloscope software.

Make sure you have sufficient storage space on your hard drive

While rotary hard drives with 1TG (Terra Byte) of storage space have become common, solid-state hard drives with more than 500GB of storage space are eye-wateringly expensive. However, since some diagnostic software suites sometimes require an additional up to 50GB of space to make their page files work smoothly, you can usually only fit two, or at most, three diagnostic software suites on a 500GB hard drive.

Bear in mind though that the more software you install, the less storage space you have available to store test results, scope traces, and the like. In practice, this means that depending on the number of vehicle brands you are planning on working on, you might have to run a dedicated laptop for each vehicle brand to ensure you always have enough RAM, processing power, and storage space available. However, there are ways to get around this, and this is what this writer does-

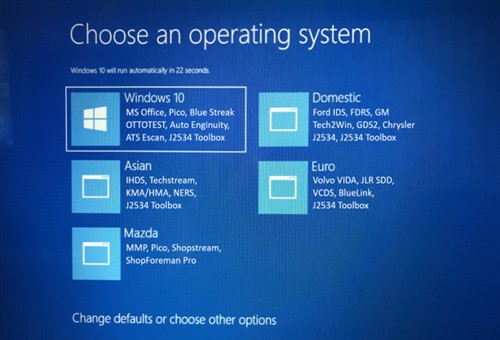

1) He uses two laptops, each equipped with a 500GB solid-state hard drive, and all his diagnostic software suites are divided between the two computers. Refer to the image at the top of this section that shows several software suites, but with each suite installed in a dedicated partition on the hard drive. In this writers' setup, each partition also contains a copy of the Windows 10 operating system, which means that each partition is effectively a different computer

2) He does not store any test results, scope traces, graphs and the like in any partition to prevent conflicts. All obtained test data is stored on a previously formatted 250GB flash drive during a diagnostic procedure. When the procedure is completed, test data is transferred to both an external 2TB hard drive and a cloud-storage facility to ensure nothing is lost. Analysis of obtained test data is then done from the flash drive on yet another computer before the flash drive is formatted again for the next procedure. This might sound cumbersome and expensive, but this method was developed after several incidents that caused the loss of test results, so make sure you develop a system that prevents your test data from getting lost or corrupted

3) He does not use any of his computers for anything but diagnostics, and he does not let anybody borrow or use them for any reason, or under any circumstance

Be wary of operating system updates

This writer has no experience or knowledge of operating systems other than Windows, and over the years, he has learned that some versions of Windows are, or will never be as stable as others had been. Windows 10 is a good case in point; while it has improved greatly since its inception, and updates are no longer forced as strictly as they had been, Win 10 is still a work in progress. Thus, as a practical matter, Win 10 is often broken by updates or upgrades that are intended to fix things that in Microsoft's opinion, are not working as well as they might.

We need not delve into the details of Win 10 operating system updates that are known to have broken millions of computers over the years here. However, we need to say that since most diagnostic software suites are designed specifically to run on Win 10, it is a bad idea to download and install all and any Win 10 updates as soon as they are released.

Apart from having sufficient "elbow room" on a hard drive to work smoothly, the single most important thing a diagnostic software suite needs to continue working smoothly is a stable operating system. Updating Win 10 is perhaps the easiest way to ensure (albeit inadvertently) that you have an unstable operating system, but how do you prevent updates from downloading and installing automatically?

Since you cannot disable the Update Service permanently from within Win 10, the only thing to do is to download and install third-party software that can turn the Update Service on and off on demand. The alternative is to use a dedicated laptop for internet searches and communications with technical websites and technical support services for your software, and not to connect any of your diagnostic computers to the internet.

Note that it is important not to disable the Update Service permanently because not all updates are bad; in some cases, especially updates to the .NET framework (or your JAVA script, which is a basic and absolute requirement for GM diagnostic software to work without crashing) can improve a computer's performance measurably. However, not all such updates always add any value either, so if you can turn the Update Service off for as long as you want, you can investigate all new updates to see if they are beneficial (or not, as the case may be), before you install them.

The point of the above is that if your laptop runs smoothly, reliably, and does not freeze or crash unexpectedly; don't attempt to fix what is not broken, which leaves us with this-

The enactment of the Mandatory Data Sharing scheme will not only represent a sea-change in the way we can do high-level diagnostics but also in terms of the time and money most independent mechanics and repairers will need to invest just to get started.

In this writer's experience, the learning curves involved in mastering dealer-level diagnostic tools, and becoming proficient in automotive systems that he'd had no access to before tackling dealership-level diagnostics are as steep, if not steeper, than any other learning curves he has encountered in his professional career. However, there are upsides as well, not the least of which is the fact that it is no longer necessary to refer customers to dealerships because some software adaptations, relearning procedures or control module programming functions on some vehicles could not be performed even with high-end generic scan tools. Some of these skills admittedly took a long while to acquire, but everything in life is a learning experience, and if this writer could learn new skills at what some would consider an advanced age, you can, too.