If you are older than about 40, you will no doubt remember a time when timing chain failures were so rare that they were (almost) unheard of. In fact, before the advent of direct fuel injection systems, timing chains typically outlasted engines, and so the only times we replaced timing chains and sprockets was when we rebuilt engines for whatever reason.

So, what changed? Why do timing chain failures now seem to be a major failure point on many, if not most engines with direct fuel injection? The answers to this question might surprise you, but it is important to understand that in the context of modern engines, timing chain failures include instances where chains and sprockets become so worn out that major camshaft phasing issues begin to occur. Put differently, “timing chain failures” are not limited to cases of timing chains snapping or breaking, although this does happen more often than you might have thought. Thus, in this two-part article, we will discuss the two main causes of timing chain failures on engines with direct injection, but before we get to specifics, we need to dispel a common misconception about timing chains by stating that-

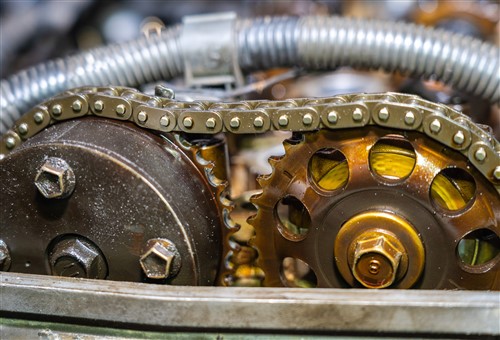

Contrary to popular belief, timing chins do not stretch, although they do become elongated as the result of mechanical wear between the roller pins and the link plates. While the amount of wear at each link pin is usually minuscule, all these minuscule amounts of wear add up along the length of the chain, which eventually alters the effective pitch of the chain.

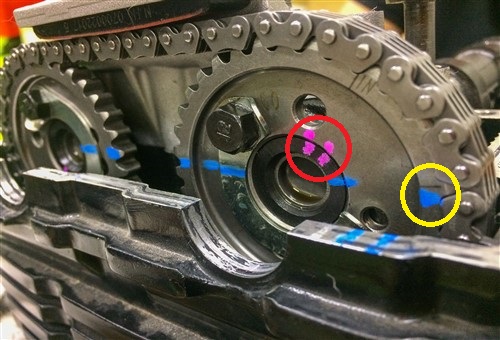

The image above illustrates this point. This engine belonged to a regular customer of this writer who once decided to replace the crankshaft bearings for reasons that were not entirely clear at the time. Nonetheless, the engine's owner made his own timing marks before stripping down the engine, (as shown here by the blue and pink paint marks) to avoid mistakes later on during reassembly of the engine.

However, upon reassembling the engine using most of the old parts, the customer found that despite his best efforts, he could not get the pink timing marks on the camshaft and camshaft sprocket to align as perfectly as they were when he made them before disassembling the engine. Now, given that this person was a semi-skilled DIY mechanic at best, he could be forgiven for thinking that the small deviance in the pink timing marks was a major issue when, in fact, this deviance is an expected feature of worn sprockets and timing chains on high mileage engines.

Nonetheless, it took a considerable amount of time to persuade this DIY mechanic that the small deviance between his timing marks on the camshaft would not cause overly-serious issues with the engine's valve timing, the situation was not ideal since the timing of the intake camshaft would always be slightly advanced, and that the only way to correct this was to replace the timing chain and all the sprockets.

Two weeks later, the customer reported that replacing the chain and sprockets resolved his problems with the timing marks, but he also reported that the old chain was almost 3mm longer than the new OEM chain.

Taken over the length of the chain, this elongation was too small to show noticeable wear on individual link pins, but holding the old chain so that the link pins were vertical, he did notice a pronounced downward bend in the chain, which was proof positive that the link pins were worn out, as opposed to the chain being stretched over its length.

Now that we have gotten that out of the way, let's look at two of the leading causes of timing chain failures on modern GDI engines, starting with-

We have all seen emulsified oil* (like the example shown here) on the underside of oil filler caps, and while it is often tempting to think that the most common cause of emulsified oil is blown or damaged cylinder head gaskets that allow engine coolant into the cylinders, damaged head gaskets is, in fact, NOT the most common cause.

* Since engine oil and water do not mix readily or dissolve into each other, the substance we commonly refer to as "milkshake" is an emulsion of oil, water, and certain additives in oil. The sole purpose of such additives is to produce an emulsion to prevent water in oil from separating and sinking to the bottom of the sump from where it could be sucked in by the oil pump and pumped throughout the oil circulation system. While the lubricity of an emulsion of oil, water, and additives is markedly lower than that of clean oil, pumping oil that contains water through an engine is better than pumping occasional slugs of almost pure water through a modern engine.

In practice, the most common cause of emulsified oil is the combustion process that produces pure water as a waste product, and although most of this water is expelled through the exhaust, some of it necessarily finds its way into the sump past the piston rings where it emulsifies with the oil and some oil additives.

There is no practical way to prevent this from happening, and the process begins immediately after starting the engine after an oil change. However, it does take some time before we begin to see the resulting emulsion, since for the most part, it only becomes visible in the form of a "milkshake” in oil that is long overdue for replacement, assuming of course, that no coolant is seeping past the head gasket(s).

Nonetheless, regardless of whether water in oil is visually detectable, the presence of water in oil has hugely harmful effects on many internal components, such as timing chains. We need not delve into the finer details of the chemistry involved, but suffice it to say that sulphur, which is naturally present in mineral base oil, combines with water under some conditions to form sulphuric acid while the combustion process also produces nitric acid, some of which dissolves into the engine oil via various complicated chemical and physical processes.

NOTE: If an engine uses ethylene glycol-based anti-freeze and some of the coolant leaks into the cylinders, the combustion process will oxidise (convert) all of the leaked ethylene glycol into five more corrosive acids, these being-

- and acetic acid, which is particularly corrosive. As a point of interest, the "vinegary" smell you get after applying some silicone sealers is acetic acid that forms during the sealer's curing process. In practice, acetic acid is so corrosive that all car manufacturers now forbid the use of sealers that form acetic acid in any type of body repairs that involve the sealer coming into contact with bare metal anywhere on the vehicle, which brings us to-

It could be argued that all of the above also occurred on pre-GDI engines, and that would be true, but bear in mind that a significant percentage of GDI engines’ efficiency comes from significantly reduced parasitic power losses. For the most part, these reductions stem from GDI engines sacrificing less power on pumping “thin” ultra-low viscosity oil that has the consistency of water through small dynamic clearances via optimized oil circulation systems than pre-DGI engines sacrificed to pump thick, syrupy oil through larger dynamic clearances via poorly designed oil circulation systems.

The above is saying a lot, but in the context of the lubrication requirements of modern GDI engines, oil viscosity is arguably the single most important aspect of the latest GF oil formulation standards because any measure of “thickening” of the oil has a direct and detrimental effect of the pumpability of the oil. As a practical matter, reduced pumpability reduces oil flow rates, which affects the lubrication of critical parts such as timing chains, which are fed a limited quantity of oil even under perfect conditions.

Thus, since the presence of excessive amounts of acids in oil causes changes in the viscosity of GF-standard oil, timing chains, timing sprockets, chain tensioners, and chain guides often do not receive sufficient quantities of oil to ensure their proper lubrication at low engine speeds because the oil pump simply cannot supply enough of the acid-thickened oil to all moving parts in the engine, which leaves us with-

In Part 2 of this article, we will explain how the combined effects of a lack of proper lubrication, corrosion caused by acidic oil, and low-speed pre-ignition in GDI engines reduce the service lives of timing chains and associated components.