Oil consumption has become somewhat of an increasing issue, partly due to extended service intervals and the honest fact that vehicle owners rarely check their engines oil level, however this is partly alleviated by the presence of oil level sensors in modern vehicles.

Is there a specific number that we as mechanics deem ‘normal’ for oil consumption across the board? Let us know in the Mechanic.com.au Private Facebook Group

Internal Oil Consumption

Assuming an engine has none of the typical external leaks such as rocker covers, sump gasket, rear main etc, let's have a think about how oil enters the engine through internal ‘leaks’.

Such examples might include via the intake manifold on some v-configured engines, shaft seals on turbocharger equipped vehicles or worn valve stem seals on intake valves particularly on deceleration or extended idle periods.

Besides the obvious loss of engine oil, spark plugs will often show some accumulation of oil ash on the electrodes, sometimes noted to be on the side of the intake valve/s depending on the dynamics of the cylinder head. Oil consumption through the exhaust valve is less common as a positive pressure is typically generated.

All that being said, the majority of internal oil consumption leads us to our next section.

Sealing the Cylinders

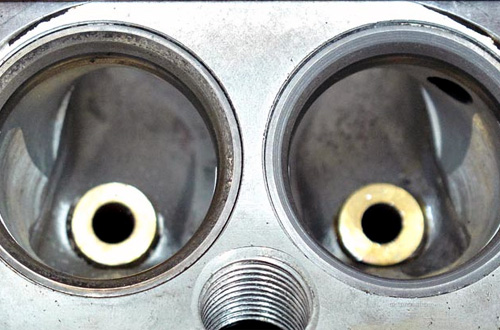

A typical indication of engine oil passing past the piston rings is oil washing. In order to properly understand oil consumption caused by improper cylinder sealing we first need to properly understand piston ring design.

Many top compression rings are flat with a convex outer edge that features a molybdenum insert. This insert retains oil and is resistant to elevated combustion temperatures.

Oil washing is an indication of engine oil passing through the piston rings. To better understand ring-related oil consumption, let’s look at piston and piston ring design. For example, many top rings are flat with a convex or barrel-shaped outer edge that contains a molybdenum inlay. The moly inlay retains oil and is resistant to high combustion temperatures.

Besides also sealing against compression, the next compression ring scrapes oil into the crankcase. This ring is generally shaped like a dish with only the bottom edge contacting the wall of the cylinder. When the pressure of combustion increases it flattens against the ring land forcing the outer width of the ring to seal combustion gases within the cylinder. When the combustion load is removed, the ring returns to its normal shape, scraping the oil back into the crankcase.

Finally the bottom rings job is solely to scrape engine oil back into the crankcase and is often constructed of three sections; a vented ring expander and two steel rails that fit over the expander. This vented expander allows the oil to flow inside of the piston and into the crankcase.

In an effort to further meet emissions standard, the clearance between the piston and the cylinder is further diminishing.

The engines of yesteryear had considerably larger piston to cylinder clearances to allow for thermal expansion however the high silicon content in aluminium pistons do not suffer this issue to the same extend.

Most typical petrol engines use narrow low-tension piston rings allowing a longer lifespan due to less circumferential pressure against the cylinder.

Improved modern boring and honing techniques allow rings to bed in quickly and after this period, a coarser cross-hatch pattern remains on the cylinder wall to keep the piston rings sufficiently lubricated.

Oiling the Engine

The clearance between the conrods and bearings also has an effect on oil consumption due to the splash lubrication of the cylinder walls and pistons. As a rule of thumb, doubling the conrod bearing clearance will quadruple oil flow to piston rings which can significantly increase oil consumption.

The oil must then pass through a finite clearance between the piston skirt and cylinder before it reaches the piston rings. Using a high-viscosity oil in a new engine reduces the lubrication and cooling of low-tension piston rings, which can be a serious problem on turbocharged, high-performance engines. Another issue with using high-viscosity oil is that it might prevent low-tension piston rings from contacting the cylinder wall, which can increase oil consumption.

As we mentioned above, oil slinging off the crankshaft not only lubricates the rings, but cools them as well. Since high-viscosity oil reduces oil flow through the connecting rod bearing, cylinder lubrication and cooling will be adversely affected.

While on the one hand we’re trying to reduce oil flow to the piston rings, on the other hand, the oil film must reach the top of the cylinder wall. High-viscosity oils might not adequately lubricate the top and second piston rings, especially during cold startups. The flash point of the oil must also be high enough to resist vaporising under high cylinder wall temperatures. Using non-synthetic base oils in synthetic applications allows this oil film to be burned away during combustion, whereas synthetic oils tend to remain in place in the upper cylinder.

In practically all cases, synthetic oils not only protect the upper cylinder, but also protect the top and second piston rings from momentarily micro-welding to the cylinder wall during high-load driving conditions. As the vehicles kilometers accumulate, synthetic oils also keep pistons free of varnish deposits that can cause low-tension piston rings to stick in their grooves.

Following the recommended maintenance intervals and using quality engine oils goes a long way toward preventing excessive oil consumption on modern engines.

Answers to our Private Facebook Group Quiz

How did you do?

1) Excessive compression ring blowby will force engine oil into the intake air ducting or intake manifold. - TRUE

2) Oil consumption with no apparent oil smoke often indicates collapsed oil control ring expanders or worn oil control rings. - FALSE

3) Oil ash deposits on spark plugs and upstream oxygen sensors are the best indicators of excessive internal oil consumption. - TRUE