Customer states intermittent poor idle quality and drivability and erratic operation of temperature gauge.

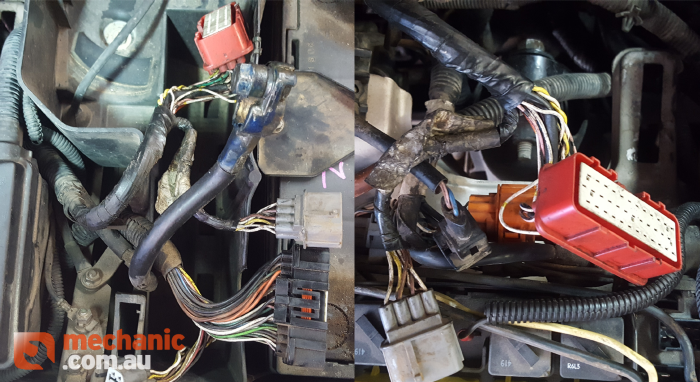

Oil ingress into main engine wiring harness back to engine control unit caused by a faulty fuel injector harness located under the rocker cover.

Disconnect the battery and remove battery/fusebox cover to gain access to engine control unit.

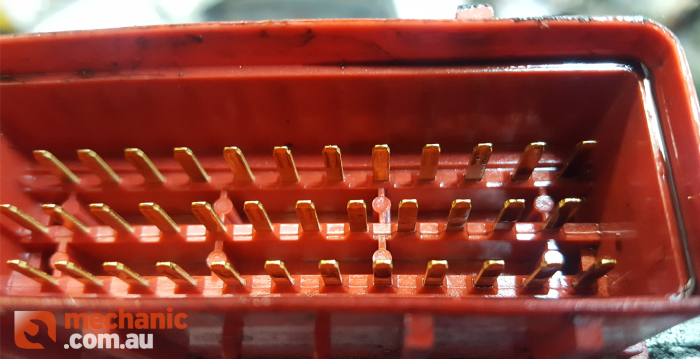

Remove engine control unit and check for oil contamination at red harness connector.

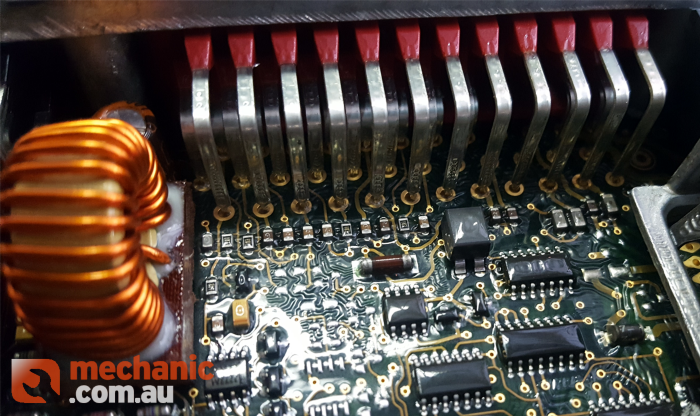

The engine control unit was opened on this occasion to check for oil contamination to the circuit board but upon disassembly it is evident that the harness connectors are sealed to the terminals making it highly unlikely to occur. We do not recommend routine inspection of the circuit board as the lid is sealed to the engine control unit case.

Thoroughly clean any oil from the engine control unit harness connectors with a suitable contact cleaner.

Proceed to remove the main engine wiring harness which terminates at the following locations and thoroughly clean all connectors with a suitable contact cleaner.

(Note: The glow plug connect boots may be perished and remain on the glow plugs, make sure you remove any perished boot material from the glow plugs before attempting to fit the new wiring harness)

Remove the rocker cover to access the diesel injector wiring harness.

Remove the injector wiring harness and clean injector terminals with a suitable contact cleaner.

Ensure the hole in which the injector wiring harness connector seals is free from any burrs or contamination to ensure a good seal on the new harness o-ring.

Supply and fit a new injector wiring harness and ensure it is correctly seated in the channel and that the injector connectors are securely fitted.

Clean the rocker cover and head mating surfaces and supply and fit a new rocker cover gasket.

When replacing the rocker cover, ensure that the gasket nearest the bulkhead stays in position and does not get pinched.

Feed the new wiring harness onto the engine, connect as required and ensure the harness is correctly secured and not tight in any areas. Pay particular attention that the section of the harness near the engine coolant temperature sensor is not able to come into contact with the exhaust gas recirculation pipe.

Reconnect the battery, carry out a full system scan and clear any diagnostic fault codes.

Start engine and visually inspect harness and rocker cover for leaks.

Road test vehicle and repeat system scan. Check live data from engine sensors.

Do you have anything to add to this fix?

If so, please send us an e-mail at: [email protected]