If all the moving parts in any modern internal combustion engine were equal in terms of their contribution to the power an engine develops, pistons would be the first among equals since pistons do most of the work. In this context, "work" means absorbing the extreme heat of controlled chemical explosions, transferring the cyclical loads of combustion events to the crankshaft, and coping with rapid and extreme changes in velocity without breaking, fracturing, melting, or deforming.

In addition, pistons have to do all of the above billions of times during an average engine’s lifetime, which makes the average piston a marvel of chemical engineering, metallurgy, and design. In fact, pistons very rarely fail because of design or construction defects, and like piston ring failures, pistons almost invariably fail for reasons that do not involve the pistons themselves. Nonetheless, like piston rings, pistons largely lead secret lives in the sense that the root causes of issues that affect their function, operation, and condition often only become apparent when one or more pistons on an engine fail- sometimes, catastrophically.

Unfortunately, few mechanics in general mechanical workshops encounter piston failures regularly. Therefore, if you have ever wondered how and why pistons fail, this short series of articles will describe the primary causes of piston failures on both petrol and diesel engines in light vehicles. Thus, as per the title of this instalment, let us start with-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

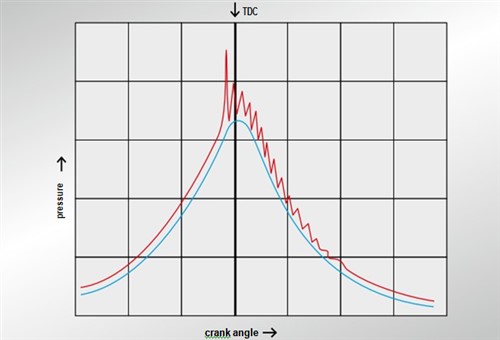

Before we get to the specifics of how abnormal combustion affects pistons, we need to explain what the above graph represents. In short, it shows how a normal combustion event (represented by the blue trace) differs from the erratic and chaotic conditions of an abnormal combustion event, shown here by the red trace.

Note, however, that the red trace does not represent any specific type of abnormal combustion event. In this case, the red trace is a generic representation of the general pattern of deviations that occur between normal and abnormal combustion events. Nonetheless, this example is representative of all types of abnormal combustion events, which incidentally, is largely prevented by the design of piston crowns and combustion chambers.

So, in practice, in a normal combustion event, we would see a steep but predictable rise in pressure, followed by an equally steep and predictable decrease in pressure as the piston moves downward on the power stroke. This characteristic is true for both petrol and diesel engines, even though in petrol engines, the combustion process starts at a single point in the combustion chamber, while in diesel engines, the combustion process starts at multiple points throughout the compressed gas mixture. As a general rule, the combustion flame front in both diesel and petrol engines propagate at a speed of between 5 metres per second and about 30 metres per second, and the combustion pressure rarely (if ever) exceeds 3-5 Bars of pressure per degree of crankshaft rotation.

However, in abnormal combustion events in both petrol and diesel engines, such as might happen when the air/fuel mixture ignites prematurely, the initial rise in pressure may be small, but the pressure rises extremely fast* as different parts of the mixture ignite unevenly while the piston is still moving upwards. In practice, the uneven ignition of the air/fuel mixture sets up extremely violent pressure waves in the cylinder, each of which is compounded by the increasing pressure caused by the continuing compression stroke.

* In serious cases of abnormal combustion, the combustion pressure can exceed the maximum allowable combustion pressure by a factor of three or more. Put differently, the combustion pressure per degree of crankshaft rotation can be as high as 15 Bars or more- albeit for periods that are measured in milliseconds. Nonetheless, the cumulative effects of such excessively high combustion pressures over extended periods include, but are not limited to-

Moreover, the pressure waves begin to oscillate, disrupting the combustion flame front even more, which in turn, can, and often does, cause combustion to occur in isolated pockets throughout the cylinder as the piston continues downwards on the power stroke.

Worse, though, unlike normal combustion events in which the combustion flame front never touches the piston crown or the cylinder walls, combustion that occurs in isolated pockets can be chaotic enough to come into contact with cylinder walls and/or piston crowns. If this happens over a sufficiently high number of combustion cycles, the chaotic pockets of combustion can remove lubricating oil films from the cylinder walls, and burn holes in piston crowns, which sometimes, presents us with a kind of-

We have all dealt with the effects of abnormal combustion: loss of power, misfires, increased fuel consumption, increased oil consumption, among others, some of which we sometimes misdiagnose. Thus, from a diagnostic perspective, we sometimes fail to consider all the factors that cause or contribute to abnormal combustion, which creates situations like the classic "which came first, the chicken, or the egg?" conundrum.

In the case of failed pistons, though, it sometimes happens that we do not always weigh the factors that cause abnormal combustion correctly. For instance, we do not always appreciate the fact that normal combustion is more a function of piston/combustion design and the combined effects of several laws of physics than it is a function of advanced engine and fuel management by "smart" computers. Of course, this is not the same as saying that advanced engine management protocols are not important. Far from it- engine management protocols are the foundation that makes the combustion of fuel and air mixtures possible in the first place. However, the fact is that piston/combustion chamber design coupled with the physics of the adiabatic heating of gases is the primary driver of sustained stable combustion in all internal combustion engines.

Thus, given that piston design is crucially important, this is where the chicken or the egg situation becomes relevant, and while we need not delve into the physics of unequal pressure and heat distribution here, we do need to consider the following questions-

If you see abnormal combustion on a customer's vehicle, did a bad piston design create the abnormal combustion? Or, did engine management or component failures, such as leaking injectors create abnormal combustion conditions that eventually damaged some (or all) of the pistons in the customer’s engine?

This is neither an idle nor a rhetorical question because there are definitive right or wrong answers. However, before we jump to conclusions, we need to consider the fact that unless we correct the underlying problem, the abnormal combustion and subsequent piston damage will happen again. So how do we begin to approach the problem of differentiating between cause (abnormal combustion) and effect (damaged or destroyed pistons) without dismantling the engine, which in any event, may or may not always yield useful diagnostic information?

Well, if you do not diagnose these kinds of issues often, it can sometimes be difficult to distinguish between the cause and effects of abnormal combustion as it relates to piston failures. However, making accurate diagnoses becomes a whole lot easier if you remember the following general rules of thumb-

The above is saying a lot, so to keep things simple from this point on, we will discuss the types, causes, and effects of the three principal types of abnormal combustion separately and in some depth, starting with-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

On petrol engines*, glow ignition is usually (but not always) caused by a heat source in the cylinder other than the spark plug. In this example from a petrol engine, the heat source was a glowing exhaust valve that caused premature and, therefore, uncontrolled ignition. In this case, uncontrolled ignition heated one side of the piston to the point where it melted past the oil ring.

* We will discuss the effects of glow ignition on diesel engines in the next section.

It is important to note that in petrol engines with hemispherical combustion chambers, the pressure distribution in the cylinder can concentrate heat caused by abnormal combustion in a point that roughly corresponds to a point on the piston crown that coincides with an (imaginary) extension of the spark plugs' axis.

This also applies to cases where the spark plug is not the abnormal heat source, but in these cases, the piston crown’s quenching area plays a decisive role. In engineering terms, the term “quenching area” refers to the part of the piston crown that is closest to the cylinder head when the piston is at TDC. In the example shown above, the raised “ring” around the outside circumference of the piston is this particular piston’s quenching area.

As a practical matter, the function of the quenching area on any piston is to force or squeeze some of the intake charge towards the centre of the cylinder to bring more of the intake charge closer to the spark plug electrode. This function is crucially important in improving combustion, but the downside of quenching areas is that they absorb more heat and retain it for longer than non-quenching parts of the piston crown.

Thus, since these areas are subjected to higher thermal loads than other parts of the piston crown that shed their heat more easily, the thicker, hotter quenching areas are the points where pistons start to melt first, and sometimes, within only a few seconds of uninterrupted operation under glow ignition conditions, which brings us to the most common-

The most common causes are much the same across most petrol engines, and these could include one or more of the following -

Incorrect or unsuitable spark plugs

The heat range of a spark plug refers to the temperature a spark plug needs to reach to clean itself by burning off carbon deposits or residues. Therefore, if the heat range of installed spark plugs is too low, the electrode end of the spark plugs can heat up to past the point where carbon deposits oxidise. Essentially, the ends of the spark plugs heat up so much that they begin to act like glow plugs in diesel engines in the sense that they can initiate premature ignition of the air/fuel mixture.

Excessively lean mixtures

In some standard engines, an excessively lean mixture can raise combustion temperatures to the point where the pistons become so hot that the pistons begin to radiate enough heat to initiate premature ignition. Note, though, that while this condition is rare on standard engines, some non-standard engine management programming can create excessively lean conditions under some operating conditions

Overheated exhaust valves

While overheating of exhaust valves is relatively rare on new standard engines, it is a common problem on a) high-mileage standard engines and b) on modified or rebuilt engines. Some of the principal causes include-

NOTE: Other potential causes of glow ignition on petrol engines involve issues with fuel quality, octane rating, and fuel contamination, but we will discuss these issues in a follow-up article. For the moment, though, let us look at -

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

This image shows the effects of glow ignition on a piston from a diesel engine. In diesel engines, glow ignition typically damages pistons through a process of erosion of the piston material by tearing small amounts of material from the structure of the piston in a process that is largely analogous to cavitation on high-speed boat propellers.

In severe cases, such as this example, the violent removal of material causes small, extremely hot areas to develop over the entire surface of the piston crown. If the heating of the piston crown continues uninterrupted for longer than about 30 seconds or so, the piston material can begin to melt in a process that could become self-sustaining if the piston's temperature reaches a critical threshold.

As shown here, the melting process can sometimes continue to a point below the top compression ring. In such cases, melted piston material is usually forced into the clearance between the piston and the cylinder wall to become wedged between the piston and the cylinder wall, which destroys the film of lubricating oil on the cylinder wall, which in turn increases the piston's temperature even more. One common result of this is that the piston often seizes in the cylinder bore, as shown here by the deep scoring on the piston skirt.

However, not all piston erosion processes are as severe as shown in this example: in some cases, such as when the glow ignition is interrupted after a few seconds, the pistons may suffer significantly less damage, such as in the example shown below-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

In this example, the glow ignition process damaged the fuel injector, which could no longer inject fuel into the cylinder. In this particular case, the failed injector interrupted the glow ignition conditions. In this case, the erosion around the piston crown could/did not progress beyond the first compression ring, and although the damage to this piston is not as severe as in the previous example, this piston is no longer useable, which brings us to the most common cause of glow ignition on diesel engines, this being-

Although glow ignition primarily occurs on common rail diesel engines, the effects of glow ignition are worse when it occurs on older, unit injection engines. There are several reasons for this, but for the most part, it is because the fuel on unit injection engines is not as finely atomised as it is on high-pressure common rail systems. Moreover, if a pre-combustion chamber on a unit injection engine is damaged in any way, that engine effectively becomes a direct injection engine.

For instance, mechanical injectors that do not close off completely after an injection event can set up severe pressure oscillations in the fuel lines. In cases where the pressure oscillations are severe enough, they can partially open the injectors again, which could inject one or more additional volumes of poorly atomised fuel into the cylinders after combustion had started.

In cases where combustion had already been partially completed, the oxygen-poor conditions in the cylinder cause the large fuel droplets to ignite partially, and instead of mixing with the combustion products already present in the cylinder (as might be expected), the pressure distribution inside the cylinder forces the glowing globules of fuel into the space between the piston and the cylinder to the level of the top compression ring*.

*This phenomenon does not occur on petrol engines, but since the dynamics of diesel combustion is a hugely complicated subject, this aspect of piston failure falls outside the scope of this article. Therefore, we will discuss diesel combustion processes in some depth in a follow-up article.

In practice, these globules of fuel are extremely hot, and if the process of glow combustion continues uninterrupted, subsequent compression and ignition cycles further heat them to the point where they initiate localised melting of the piston material. If the glow ignition condition continues, inertial forces begin to fling off small amounts of molten piston material in a process (of erosion) that can become self-sustaining under some operating conditions. This can happen even in cases where the underlying glow ignition conditions have been removed or interrupted.

Note that cracked or eroded precombustion chambers can accelerate and aggravate the erosion process because damaged precombustion chambers disrupt the propagation of the nascent combustion flame. In practice, this can, and often does, turn the precombustion chamber into a kind of flamethrower that ejects the poorly developed combustion flame into the larger combustion chamber in an uncontrolled manner.

This effect can cause the combustion flame to reach the surface of the piston crown, thereby increasing the piston's temperature even further, which in turn increases the rate of erosion of the piston in the space between the cylinder wall and the piston, which leaves us with-

Other possible causes of piston failure on diesel engines involve several issues that reduce and/or eliminate dynamic clearances between pistons and cylinder walls, which we will discuss in a follow-up article.