In the previous article in this series, we discussed abnormal combustion as a major cause of piston failures on both petrol and diesel engines. We also made the point that pistons very rarely fail as a result of inherent piston defects. However, in cases where pistons seize in cylinder bores due to insufficient piston to cylinder wall clearances, it can sometimes be very difficult to identify the root cause(s) of the seizure(s) because of the damage caused to both the piston(s) and the cylinder wall(s).

Moreover, even if the pistons did not actually seize in the cylinder bores, the damage to both the piston(s) and the cylinder bore(s) often make it impossible to determine if the correct pistons had been fitted or if the cylinder walls were oval or tapered to the point where dynamic clearances were reduced or eliminated. Thus, in this article, we will take a closer look at some of the issues that cause, or contribute to the elimination of piston clearances on both diesel and petrol engines. Before we get to specifics though, we need to look at-

Image source: https://hotrodenginetech.com/are-your-pistons-round/

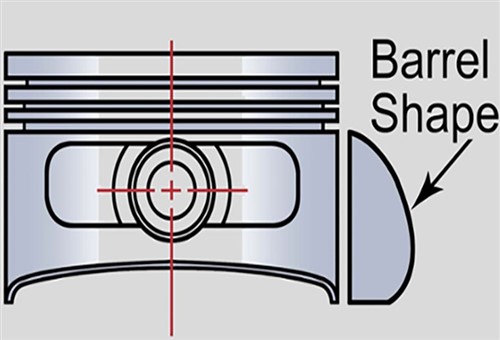

We all know that pistons are oval when measured around their skirts, but one thing that is not so obvious is the act that pistons are also somewhat barrel-shaped. What we see as the straight, parallel sides of the skirt are, in fact, curved surfaces, as shown in this exaggerated example.

Since pistons perform small rocking motions of up to about one-tenth of a degree from the vertical in all engines, the barrel-shaped sides allow for reduced wear of both the piston skirt and cylinder walls, but there is a complication. This complication is the fact that the radii that give aftermarket pistons their barrel shapes vary significantly not only between brands of pistons, but also between cast and forged pistons made for the same application by the same manufacturer.

This is further complicated by the fact that the points where the diameter of the barrel shape is the biggest also differ. While this diameter is often biggest at the centre-line of the gudgeon pin on some pistons designs and types, this same diameter may be located at the base of the gudgeon pin hole on other piston types and/or designs. In practice, this means that unless this point is determined very carefully it is easy to arrive at the wrong piston diameter measurements.

Sadly, there are far too many piston types and designs available today to list all or even most variations of this critical dimension here. Nonetheless, the point is this; OEM pistons fitted to new engines typically provide many years of silent, efficient, and reliable service, while many aftermarket pistons fitted to rebuilt, reconditioned, or modified engines often do not for reasons that will become clear later on in this article.

To understand why OEM pistons typically outperform and outlast many aftermarket piston types and designs, we need to understand that although modern mass-production methods do not produce perfect engines, the average mass-produced engine is almost always machined to closer tolerances and higher quality metal finishes than almost any rebuilt, reconditioned, or modified engine.

However, despite the above, even the most advanced mass-production methods and quality testing systems can't ensure that all cylinder bores in all mass-produced engines are 100 per cent identical in terms of their dimensions and surface finishes. Therefore, and being aware of this fact, the piston designs OEM manufacturers select for each of the engines they produce represent a range of tradeoffs between cost, performance, and durability. In practice, these tradeoffs ensure that most pistons on most new engines last for at least several hundred thousand kilometres of use under the widest possible range of operating conditions and servicing regimes.

Thus, the result of suitable and appropriate tradeoffs between various aspects of piston design is that few piston failures occur in new engines, and where these failures do occur, the failure can almost always be traced back to causes that do not involve the designs and/or construction of the failed and/or damaged piston(s). Sadly, the same cannot be said for engines that run with aftermarket pistons*, so let us look at some of the reasons-

*Note that for the purposes of this article, we will ignore purpose-made, custom pistons that are made from exotic alloys that, for all practical purposes, do not expand. Since this category of pistons is almost exclusively used in highly modified racing engines that run on specialised or custom fuels, this article will focus on mass-produced pistons for general applications that are commercially available.

First off, it must be stated that high quality, branded, aftermarket pistons are not made to fail. Quite the opposite is true- reputable piston manufacturers produce products that are uniform in terms of their critical dimensions, mass distribution, thermal expansion rates, and structural integrity. Put differently, aftermarket pistons are generally fit for their purpose, and their lower cost makes them viable alternatives to OEM pistons when an engine must be rebuilt or reconditioned.

In fact, under the right conditions, most aftermarket pistons can provide the same high levels of performance and reliability as OEM pistons. However, there is a caveat to this proposition, the caveat being “the right conditions”. We will say more about “the right conditions” a bit later on, but for the moment, we need to focus on two critically important things that each have a direct bearing on the longevity of aftermarket pistons, these things being piston-to-wall (PTW) clearances, and coefficients of expansion. Let us look at these in turn-

Piston to wall clearances

|

Bore Diameter |

Clearance (Naturally Aspirated) |

Clearance (Forced Induction) |

|

70.0 mm |

0.075 mm |

0.085 mm |

|

75.0 mm |

0.079 mm |

0.089 mm |

|

80.0 mm |

0.082 mm |

0.092 mm |

|

85.0 mm |

0.086 mm |

0.096 mm |

|

90.0 mm |

0.090 mm |

0.100 mm |

|

95.0 mm |

0.094 mm |

0.104 mm |

|

100.0 mm |

0.098 mm |

0.108 mm |

The few examples of suggested PTW clearances listed here were supplied by a long-time acquaintance of this writer, who is a supplier of engine parts. Note, though, that the examples listed here apply to only one brand of high-quality aftermarket pistons that are suitable for use on petrol engines. However, this particular supplier also supplies pistons made by at least 4 other major piston manufacturers, each of which recommends different PTW clearances for each of the piston diameters listed above.

Moreover, suggested clearances differed by as much as 8 - 10 per cent between different brands of cast pistons for the same application, but there is more. For instance, suggested PTW clearances for cast and forged pistons for the same application also differed by as much as 12 per cent for some piston designs. At first glance, the big difference between suggested PTW clearances for cast and forged pistons might be explained by the facts that-

- but there are, in fact, several other equally good reasons why suggested PTW clearances differ so widely between piston brands and designs. Let us look at the main ones-

Different alloys expand at different rates

As a general rule, pistons in passenger vehicles expand about twice as much as cylinder bores do, which means that PTW clearances can be eliminated very quickly. However, to control the expansion rate of pistons, manufacturers use different aluminium alloys to produce different coefficients of expansion, which is expressed as “Micron Per Meter Per Celsius Degree”.

As a practical matter, this is an objective scale that operates at the macro level. In translation, this means that when a piece of metal is heated to a particular temperature, the change in its volume produced by being heated can be measured with standard measuring tools. Below are some examples of piston alloys in common use, as well as their specific thermal expansion coefficients. Note that alloys starting with the letter “2” use copper as the principal alloying agent, while alloys starting with the letter “4” use silicon as the principal alloying agent-

Alloys suitable for casting

|

Alloy |

Production method |

Expansion Coefficient |

|

201.0-T4 |

Sand-cast |

19.3 |

|

204.0-T4 |

Sand-cast |

19.3 |

|

208.0-T4 |

Permanent Mold Cast |

22.3 |

|

222.0-T61 |

Sand-cast |

22.1 |

|

242.0-T61 |

Permanent Mold Cast |

22.7 |

|

413.0-F |

Die-Casting Alloy |

20.4 |

|

443.0-F |

Permanent Mold Cast |

22.1 |

Alloys suitable for forging

|

Alloy |

Production method |

Expansion Coefficient |

|

2618-T6 |

Forged |

22.3 |

|

2011-T6 |

Forged |

22.9 |

|

2014-T6 |

Forged |

23.0 |

|

2024-T6 |

Forged |

23.2 |

|

4032-H18 |

Forged |

19.4 |

|

4043-H18 |

Forged |

22.1 |

|

4045-H18 |

Forged |

21.1 |

|

4032-T651 |

Forged |

19.4 |

From the above, it is clear that expansion coefficients differ significantly between different alloys, but despite this, all of the above alloys are suitable for the manufacture of general-purpose pistons. However, since the distribution of mass within pistons is not even, high-quality pistons contain non-expanding struts and/or reinforcing elements that are incorporated into the piston's structure to prevent or mitigate the unequal or differential expansion of the piston. In some designs, the piston skirt may be split to prevent differential expansion.

Piston skirt coatings

On some piston designs, you might see a coloured coating on the skirt. These coatings are intended to reduce friction and wear, and while these coatings generally work reasonably well, they are not created equal. For instance, hard ceramic coatings usually offer a measure of protection against excessive heat caused by insufficient PTW clearances, while soft, powder-based coatings offer virtually no protection at all. Depending on the piston’s price, manufacturer, and intended application, a non-friction coating can be made from a dry powdered lubricant, advanced ceramic material, or simple chemical treatments that attract and retain oil molecules.

Moreover, again depending on the piston’s price, manufacturer, and intended application, the thickness of an anti-friction coating or treatment can be anywhere from 10 microns to about 50 microns or sometimes a bit more. On high quality, branded pistons, the thickness of the coating is typically uniform and included in the piston's overall diameter, but this is not always the case on "economy line" pistons. In practice, this means that suggested PTW clearances can be reduced or eliminated on some parts of the pistons’ skirts.

Regardless of any anti-friction coating's thickness and/or uniformity though, increased friction due to insufficient clearances usually increase the temperature in the piston skirt/cylinder wall interface to the point where the lubricating oil film breaks down, which creates boundary lubrication conditions that can destroy even the hardest ceramic anti-friction coatings in a matter of seconds, which begs this question-

Image source: https://www.memoparts.com/img/cms/Documents/Piston%20Failue.pdf

This image shows one example of the wear marks caused by insufficient PTW clearances. Many other issues cause similar marks on pistons, but the surest way to identify a simple lack of a suitable clearance between the piston and the cylinder wall is to check if the marks are identical on both the thrust and non-thrust sides of the piston skirt. If the marks are identical around the piston's circumference, the cause is an insufficient operating PTW clearance.

While the above paragraph answers one question, it raises another, this being the question of why this happens so often on rebuilt or reconditioned engines, and so very rarely on new engines that have not overheated. To answer this question, we need to discuss one more aspect of how pistons behave in a cylinder. Here is how it works-

As pistons move up and down in a cylinder they not only perform small rocking motions at TDC and BDC; they also move from one side of the cylinder to the other at the midpoints between TDC and BDC. In practice, the sideways motion depends on both the engine speed and load and to a smaller degree, on the piston's mass. Nonetheless, the point is that the clearance between the piston's skirt and the cylinder wall changes all the time when an engine is running- and the only thing that prevents metal-to-metal contact between the piston and the cylinder wall is the 3-micron thick film of oil on the cylinder walls. So, on new engines, the PTW clearance is based on, and takes account of (among others things), the following-

This last point is particularly relevant because while cylinder distortions can destroy piston rings in fairly short order, cylinder distortions very rarely affect pistons in new engines directly.

In practice, all of the above points work together to ensure that pistons in new engines have enough “elbow room” so to speak, to ensure that the pistons can always move freely under all reasonable operating conditions, which brings us to-

NOTE: What follows is in no way intended to belittle or malign the knowledge, skills, and/or professionalism of professional engine rebuilders. In fact, while most engine rebuilders can, and do rebuild modern engines to exceedingly high standards, the large number of piston failures on rebuilt engines this writer has seen in his workshop over more than two decades suggests that at least some engine rebuilders sometimes fail to achieve the standards of excellence their colleagues are capable of.

Elsewhere in this article, we mentioned that aftermarket pistons can perform as well as OEM pistons, but we also said that this only happens if the aftermarket pistons have the right conditions to operate in. In this context, the “right conditions” would be PTW clearances that are based on the laundry list of bullet points in the previous section so let us look at some of the defects that are sometimes “built” into rebuilt or reconditioned engines-

“Wrong” or unsuitable pistons

We are not suggesting that engine rebuilders will sometimes knowingly (or willfully) install the wrong pistons into any engine. However, mistakes do happen even though the engine rebuilder may not always be directly at fault. Let's see how these kinds of "mistakes" can happen-

Engine rebuilders usually use manuals that list the dimensions of all the engines a particular car manufacturer makes. These manuals list minimum and maximum allowable deviations from standard values for cylinder bore diameters, crankshaft journal diameters, camshaft bearings, and much else besides. However, the problem with these manuals is that they list specified clearances and tolerances for OEM parts, which means that listed cylinder bore clearances rarely if ever, apply to non-OEM pistons.

In practice though, many customers demand that the rebuilder uses pistons from manufacturer X, Y, or Z, instead of OEM pistons, and it is here where the problem arises. Consider the tables with thermal expansion coefficients we listed earlier: these show that pistons made from any given alloy expand more (or less) than pistons made from a different alloy. Therefore, unless the engine rebuilder uses aftermarket pistons that are made from the same alloy as the OEM pistons, there is a very good chance that the replacement pistons might expand to the point where the PTW clearance specified in the manual might be reduced or eliminated.

It could be argued that the engine rebuilder should check on the aftermarket pistons’ specifications, but in many cases, information on which alloy was used is not available. This is distressingly common on “economy line” pistons that often only list the recommended PTW clearance, which may or may not be accurate, valid, or applicable.

Therefore, in cases where a customer specifies the use of non-OEM pistons, the engine rebuilder often works "blind", because his manuals do not list PTW clearances for every piston alloy or every piston type. Experienced engine rebuilders will, therefore (as a matter of principle) not prepare an engine to accept pistons for which all the required information is not available. This kind of information includes details on whether-

There are other things to consider, but for the most part, the replacement pistons will have the right conditions if all of the above agree with OEM specifications.

Sadly, though, the above checks often do not happen. There are several possible reasons for this: for instance, the customer may specify “economy line” pistons for which the required information might not be available. In other cases, customers may elect not to have connecting rods resized or checked for straightness, or the customer may choose not to follow the recommended running-in procedure after the engine rebuild, which leaves us with the problem of-

We can fill several volumes listing the bad choices some customers make to save some money but that would be pointless. What we can do, however, is to educate our customers; we can tell them that while there are no bad, branded, high-quality pistons, not all branded high-quality pistons work equally well in all engines.

We can also tell them that if OEM pistons are not available or if they are too expensive, the best thing to do is to select aftermarket pistons that come closest to OEM pistons in terms of dimensions, mass, mass distribution, construction method, and the alloy used in their manufacture.

In the real world though, it is not always possible to match these requirements with OEM pistons exactly, but it is possible to come very close to OEM specifications and the closer OEM and aftermarket pistons are matched, the smaller the chances are that the aftermarket piston will seize in the rebuilt engine, which leaves us with-

Although the above barely scratches the surface of what constitutes the secret lives of pistons, we nevertheless hope that you have gained some new insights into at least some reasons why rebuilt engines fail, and sometimes, in fairly short order.

Thus, to expand on this topic, the next article in this series will focus on the actual causes of specific types of piston failures in rebuilt petrol and diesel engines. We might also mention that some of these causes are entirely, and easily preventable simply by paying proper attention to some critical details during the assembly of a reconditioned engine.