Thanks to Brad Halse from B&L Mechanical Services for putting this case study together for us!

I had a 2009 VDJ79 (Toyota Landcruiser) dropped off on a car trailer yesterday with the the complaint "it barely runs".

The vehicle belongs to a local company that employs four of there own LV (Light Vehicle) mechanics that service the fleet.

Given the Denso CRD (Common Rail Diesel) system is covered in this month's news letter I thought it was rather 'good timing' to have this dropped in my lap.

The original fault was the engine simply cut out about two weeks ago, but would start & run if operating the fuel filter primer. After some testing the guys decided to change the high pressure pump.

It was on start-up they found the engine running extremely roughly, after further testing they decided to bring it to me.

The fella that did the job explained to me what he had done & tested and left it with me.

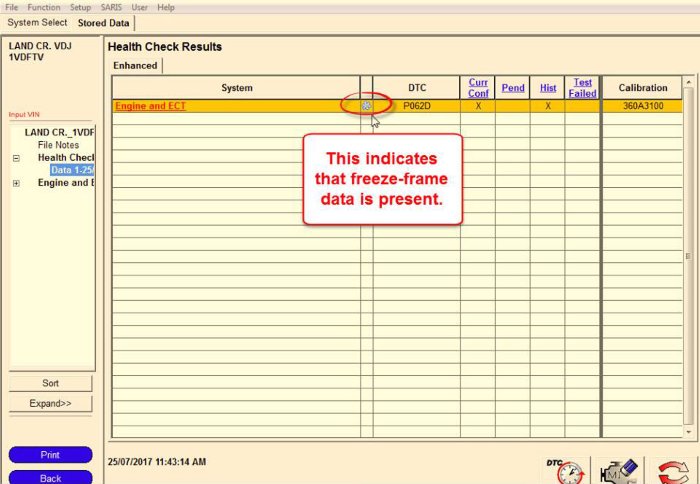

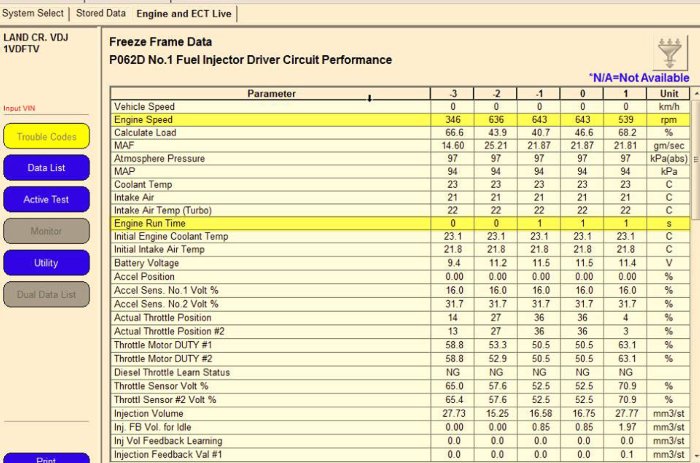

The engine would start but mifire rather badly, connecting the scan tool revealed code P062D No.1 Fuel Injector Driver Performance logged. It also had Freeze-frame data that indicated it faulted right from the first start-up.

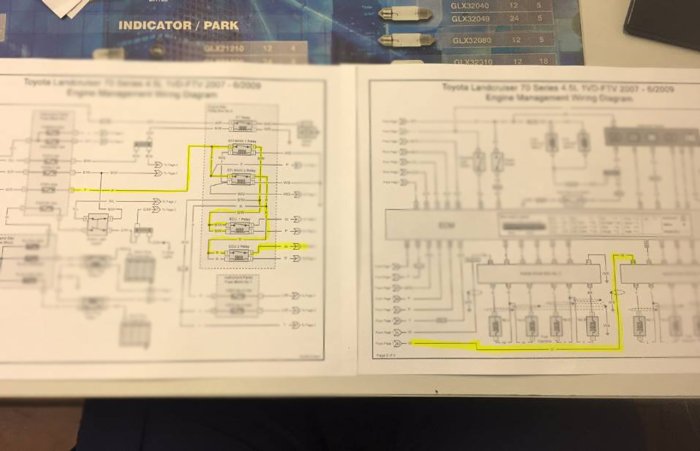

Firstly, I won't go near a vehicle without A. a wiring diagram and B. system information.

With a wiring diagram printed out I highlight the circuit in question and get a direction.

All fuses are tested & relays are checked on both control & load sides. I found the control side of EDU1 was missing a switched input (ground from pin A45 of ECM), back to the office and check the Code Set Criteria. According to Toyota the ECM monitors the injection command (IJT) and confirmation (IJF) signals for inconsistancy.

With this code logged the ECM enters Fail-Safe mode and limits power, or in this case, switches off EDU No.1 to protect the circuitry from excessive current draw. This EDU controls #1,4,6 & 7.

Given the replacement of the HP pump would require the disconnection of a lot of electrical connectors I decided to test continuity between the injector wires at No.1 EDU & injectors 1,4,6 & 7.

The first wire I tested was #1 injector & it had no continuity. Removing the female pin from the injector connector revealed the wire had broken away from the pin but was still held in the connector by the weatherseal.Temporarily connected to the injector the engine was cranked and fired instantly. The EDU was now back on line and firing these four injectors.

I didn't get a pic of the broken wire as I soldered it to the terminal for testing first, but we've all seen a broken wire before...