What is the standard remedy for steering wheel vibration and brake pedal pulsation under normal braking?

In most cases, we conclude that the brake rotors have DTV (Disc Thickness Variation) and we replace or re-machine the rotors as a matter of course, right? Well, what happens when the customer returns after a few months with the same problem?

Clearly, not all brake rotors can be bad, so there must be other factors at play, and you may be surprised to learn that the original problem was almost certainly caused solely by improper installation of the rotors. In this article, we will take a closer look at the real causes brake pedal pulsation, and what we as technicians can do to prevent it from occurring, starting with saying that-

Brake rotors don’t warp; they wear unevenly

Contrary to popular belief, brake rotors, and especially brake rotors supplied by a reputable manufacturer such as DBA don’t warp, no matter how aggressively a vehicle is driven. Yet, as we know, brake pedal pulsation caused by out-of-true brake rotors is a fairly common problem that is almost invariably attributed to warped rotors, which is almost invariably confirmed by excessive amounts of rotor run out that is easy to “prove” with a dial gauge.

So if a brake rotor is not warped, but unevenly worn, how did this happen if the rotor/brake pad contact surfaces on a brake rotor are parallel over the entire circumference of the rotor, and more so, if the rotor is running perfectly true with respect to the mounting surface on the hub? On the face of it, there would be no reason for the rotor to wear unevenly since under normal braking, the brake caliper applies an even and consistent clamping force over the entire rotor / pad contact area as the rotor rotates.

However, long experience has taught this writer that brake rotors that show run out greater than 0.05mm with a dial gauge also invariably generate thickness variations due to off brake wear as the pad makes contact with the runout high spots. This also produces brake pedal pulsations under normal braking. So from a diagnostic perspective, what really causes brake pedal pulsation: warped rotors, or unevenly worn rotors?

The first possibility, warped rotors, is easy to confirm or eliminate, and this writer has done so many times simply by rotating a bolted-down brake rotor between two dial gauges- one on either side of the rotor, with the caliper removed to allow placement of the second gauge. If the rotor is warped, two dial gauges placed directly opposite each other will show equal amounts of positive and negative run out, but this writer has never observed this.

What using two dial gauges does show however, is that more often than not, high spots occur either on both (directly opposite) sides of the rotor, or 180 degrees or so apart on opposite sides of the rotor. Moreover, high spots as indicated by dial gauges always coincide with thickness variations on the rotor, which seems to be linked to the type of brake pads on the vehicle in the sense that some types of brake pads seem to produce more pronounced thickness variations than others, which begs this question-

What causes thickness variations on brake rotors?

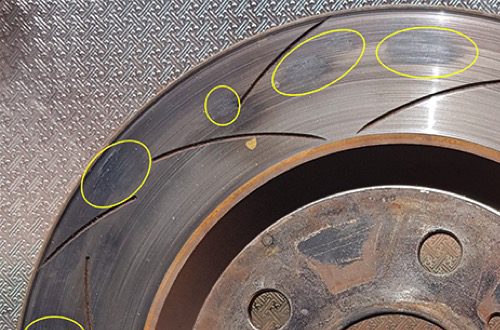

This image clearly shows material deposits of the brake pad on the rotor, and in this case, the imprint is defined by the visible layer of friction material that was transferred from the pad to the rotor when the brakes were over heated. While this happens most commonly with organic brake pads, it can also happen with some semi-metallic pad formulations, since these pads were actually designed to transfer some friction material to the rotor surface during normal use. In some cases though, the particular type of pad in use on the vehicle will wear away the high spots on the rotors, but the end result is the same; thickness variations on the rotor that cause brake pedal pulsations.

In cases like this, even high-quality brake rotors such as those supplied by DBA will be affected, since the pad material is bonded to the rotor on the molecular level. This pad material imprint will create a higher level of resistance than the rest of the rotor causing an oscillating brake torque, steering wheel vibration and pedal pulsation.

Of course, no technician can be blamed for the way some customers use the brakes on their vehicles, but in many cases, the uneven transfer of friction material from brake pads to brake rotors is the direct result of how we install brake rotors, which brings us to-

The things we forget when installing brake rotors

We all know that the mating surfaces on both the hub and new rotor must be free of dust, dirt, rust, metal shavings and other debris and we usually do a proper job of cleaning both surfaces, but how often do we actually test the run out on the new rotor after it was fitted to the hub? Can we honestly say that the newly replaced rotor is always running true, or at least, within specified run out values?

While it is true that high quality aftermarket brake rotors such as those supplied by DBA are almost certainly within OEM specs with regard to allowed run out limits, we often forget some very important things when we replace brake rotors, such as that-

Brake pad/brake rotor clearances are very small

On most vehicles, the effective clearance between the brake pad and the brake rotor is only about than one tenth of a millimetre when there is no pressure on the brake pedal, and sometimes less when a caliper piston seal is sticky. Such small clearances do not allow for much, if any brake rotor run out.

Wheel hub mounting faces are often not flat, or perfectly true with respect to the axle centre line

Long use, continued exposure to heat, vibration, shock loads, and the long-term effects of less than perfect wheel bearings can deform the mounting face of a wheel hub to the point where a rotor that is mounted on the hub will either deform when it is bolted down, or show excessive run out even though the rotor itself may be in perfect condition.

Few brake rotors are perfectly true in all axes

Brake rotors are mass-produced in huge numbers, which means that even though most randomly chosen rotors from a particular production run will conform to specs, small differences in the temperature of the manufacturing environment, wear on cutting tools used in machining process, and other factors produce dimensional differences between individual rotors. For this reason, it is important only to use rotors from high-end manufacturers such as DBA, who go to great lengths to ensure that dimensional and other differences are kept within OEM specs.

It is important to keep the above in mind, because the next section deals with-

The mistakes we (often) make when installing brake rotors

As described elsewhere, the predominant cause of brake pedal pulsations is the uneven transfer of friction material between brake pads and brake rotors that occurs when brake pads come into intermittent contact with brake rotors (even when there is zero pressure on the brake system) when significant amounts of run out is present on the rotors.

Moreover, even if the run out is less than the clearance between the pads and the rotor, this clearance can be absorbed when the rotor heats up and begins to expand. In practice, the hotter the rotor gets the more it expands, which reduces the rotor/pad clearance even further, thus progressively increasing the pressure between the pad and rotor with each pass of the high spot. The result of this chain of events is inevitable: brake pedal pulsation, and/or severe vibrations on the steering wheel when the brakes are applied.

However, there is much that we as technicians can do to prevent this from occurring, but note that what follows should not be seen as additional labour; instead, it should be treated as standard practice in all brake rotor replacement jobs that will cure recurring brake pedal pulsation issues once and for all-

Index the rotor

Indexing refers to the procedure in which the rotor is fitted onto the hub repeatedly, but in different positions to eliminate run out, but note that this procedure requires the use of thick, solid washers to allow you to torque the rotor down to the same value you would use for the wheel nuts/studs/bolts. You may have to have these washers fabricated, but make sure they are at least 10 millimetres thick, and at least 35 millimetres in diameter for the best results.

The object of this exercise is to measure run out, so mount the rotor, and torque it down. Check both sides of the rotor with dial gauge while rotating the rotor, and mark high spots on both the rotor and the hub. If the observed run out exceeds specs for the vehicle, remove the rotor, and rotate it at least 90 degrees (or one bolt hole for 5 & 6-hole hubs), torque it down again, and retest for run out.

If the run out value differs significantly from the previous value, rotate the rotor another 90 degrees or one bolthole and recheck the run out. If the run out value differs again, use the original reference marks you had made to repeat this test until either the run out meets the manufacturer’s specs, or it turns out that indexing the rotor won’t solve the issue, in which case you can-

Torque wheel nuts/studs/bolts correctly

Have you ever really wondered why all car manufacturers specify a particular torque value for the wheel

nuts/studs/bolts on their products? Of course, the primary reason is that the wheels won’t fall off when they are torqued down properly, but an equally important reason has to do with the fact that over -, under -, and uneven tightening of the wheel nuts/studs/bolts can deform or distort both the brake rotors and the wheel hubs.

All manufacturers go to great lengths to calculate appropriate torque values for each fastener on their products and wheel fasteners are particularly important since they serve a dual purpose, one of which is to stabilise brake rotors when enormous braking forces attempt to deform them.

In practice, the plane of the clamping force that slows the vehicle down is offset from the plane of the clamping force that holds the rotor against the wheel hub. This means that every time the brakes are applied, a twisting force is generated that attempts to dislocate and or deform the brake rotor, and the only things that prevents this are the correct torque value(s) of the wheel nuts/studs/bolts, and the absence of rotor run out.

As a practical matter, both over/under tightening and tightening the wheel nuts/studs/bolts in the wrong sequence has been shown to deform brake rotors, with the most deformation occurring when wheel nuts/studs/bolts are tightened unevenly, even though the correct tightening pattern was observed.

Using air wrenches to tighten wheel nuts/studs/bolts almost always results in uneven tightening due to the constantly changing and unpredictable air pressure in the system, and their use to tighten wheel nuts/studs/bolts should therefore be avoided on both steel and alloy wheels, and here is why-

Apart from the fact that air wrenches are generally not calibrated to any particular value, the first use of the wrench causes the air pressure, and therefore, its effective torque to decrease, causing the compressor to kick in, which raises the air pressure in the system again. Thus, depending on the initial torque setting on the wrench, you end with wheel nuts/studs/bolts that are torqued to wildly different values, which is almost certain to deform the brake rotor on that wheel to the point where brake pedal pulsation within a few thousand kilometres is inevitable.

The only way to avoid deformation and subsequent run out on brake rotors (assuming that the rotors were installed correctly, in the first place), is to use a properly calibrated torque wrench to tighten wheel

nuts/studs/bolts to their specified torque values. In addition, tightening should always be done in a cross-wise (aka star pattern), with the two fasteners that are the furthest away from each other being tightened in pairs, and preferably in two steps to load the rotor evenly.

NOTE: While torque sticks are often used in conjunction with air wrenches to avoid over torqueing of wheel nuts/studs/bolts, these devices should be treated with a great deal of circumspection. There are many online resources that describe comparison tests in terms of the repeatable accuracy of torque sticks, and it turns out that few brands score well in this department. Therefore, wheel nuts/studs/bolts should always be checked with a calibrated torque wrench if a torque stick and air wrench was used to ensure that all wheel nuts/studs/bolts are tightened correctly.

Conclusion

Although this article does not pretend to be the last word on uneven brake rotor wear, we hope that you find the information presented here both informative and useful, and that it will help you diagnose brake pedal pulsation issues with confidence. However, if you need more specific technical advice and/or information on any brake rotor related issues, you can visit the DBA website, which contains a variety of extremely useful technical resources.