If you have been in the car repair industry for only a few years, you might not understand why so many mechanics that have been in the industry for many years or even decades sometimes dislike, or even refuse to work on certain vehicle makes and/or models. Chances are, however, that you will develop similar dislikes and pet hates at some point in your career, but until you reach that point, you should know that just like people, cars produced in some regions of the world also have national characteristics that make them different from cars produced elsewhere in the world.

Sadly, or fortunately, depending on your point of view, these differences are not always apparent when cars are new, but they come to the fore strongly when cars from different parts of the world begin to age together in a common national fleet.

In this article, we will discuss this phenomenon in some detail, but with special reference to older cars of European manufacture in terms of a), why these vehicles all begin to suffer from misfires when they reach a certain age, and b), how to diagnose misfires on these vehicles without losing your sanity. Before we get to specifics though, let us start with this question-

All or most senior mechanics will be familiar with the adage that says that if an English car does not leak oil, it does not have any oil in it that can leak out. However, while British vehicles up to about 1990 were (in)famous for both the number and severity of their oil leaks, cars of British manufacture have improved significantly, if not greatly so, in this regard over the past thirty years or so. Thus, in practice, and except for Japanese vehicles, British cars now seem to leak no more or no less oil than cars produced in the rest of the world.

However, this article is not about oil leaks, it is about misfires, but why should misfires on older European vehicles* represent such a large percentage of customer complaints compared to say, Japanese or American vehicles of the same age?

* According this official Government source, passenger vehicles account for just more than 75% of the 18.4 million registered vehicles in the Australian national fleet. More to the point though- while the average age of vehicles in the national fleet is 10.1 years, 21.2% of vehicles are between 11 and 15 years old, while a whopping 21% of vehicles are older than 16 years. While there is no reliable information available on what percentage of vehicles older than 10 years are of European manufacture, it is reasonable to assume that at least a significant percentage of these vehicles were either imported complete from Europe or were assembled locally using European-made components.

While the above digression might be interesting to some readers, it does not answer the question of why and how European cars are different from say, Japanese and American cars. Note though that in the interests of brevity we will exclude differences in engine/fuel management programming, transmission programming, suspension configuration, and exterior lighting, and will only focus on differences that pertain to misfires. Having said that, let us look at-

Perhaps the two biggest differences between how European engineers and how American engineers design passenger vehicles involves operating conditions on the one hand, and environmental factors, on the other hand. Let us look at these differences in turn- -

American cars have always been about ride quality and driver comfort because their relatively smooth and straight roads allowed bigger cars fitted with soft suspensions. Therefore, until comparatively recently, American cars were easy to work on because there was always lots of (wasted) space that made it possible to simultaneously insert both your hands and tools into most nooks and crannies without too much trouble.

By way of contrast, most streets and the majority of roads in Europe have always been narrow and twisting, which largely prevented European manufacturers from making large cars, simply because large cars could not easily navigate some or most of the narrow streets in Europe's towns and cities. More importantly, though, as the European motoring public's demand for creature comforts in their cars grew and exhaust emission regulations became ever-more stringent at the same time, car manufacturers were forced to pack more and more components into cars that were already too small for comfort.

From our perspective as Australian technicians, this last point is particularly important, because the lack of working space in many, if not most of the engine compartments of European cars can sometimes make it extremely difficult to diagnose and repair relatively simple causes of misfires, which brings us to-

Although the Motor Vehicle Standards Act 1989 regulates the safety, environmental impact, and anti-theft performance of all road vehicles that are imported into the country in commercially viable numbers, the provisions of this Act does not compel European car manufacturers to make their products immune to the effects of extreme environmental conditions before they export them.

For instance, the wiring and electrical insulation of European cars are designed to remain functional and fault- free in conditions where temperatures of 28 degrees Celsius represent a heatwave. In these conditions, wiring insulation remains pliable, weather seals in connectors don't dry out and crumble, and harness insulation does not melt. As a result, water and moisture don't have easy ways of getting into wiring and connectors.

However, in Australia, where, as we know, temperatures can hover around the 400C mark for extended periods, the insulation of wiring on most European cars start to break down and crack within about three years. After about five years or so, the weather seals in connectors become so hard and brittle that their ability to prevent water ingress into connectors and control modules is seriously compromised.

Now you might argue that you have never seen this for yourself, but how often do you work on European vehicles that are older than about ten years? Those of us who often work on these vehicles regularly see cracked wiring insulation, "tired" terminals in connectors, connectors without weather seals, and harnesses without insulating covering because the insulation had melted and dropped off.

Long story short though, not all of these issues always cause misfires, but when you do encounter misfires on old European vehicles, it is sometimes difficult to distinguish between cause and effect. For instance, is a random misfire the result of a component failure, or the result of wiring defects? Similarly, is a persistent, permanent misfire the result of a mechanical engine issue that is fouling a spark plug? Alternatively, is it perhaps the result of a fuelling issue, such as a clogged injector, or again, is it the result of defective wiring?

If you do not have much experience of older European vehicles, these questions might seem either self-explanatory or nonsensical, but we can assure all readers that they are in fact, perfectly reasonable questions to ask when diagnosing misfires on old European vehicles, which brings us to-

The first and most important thing to remember about old European vehicles is that their misfire detection systems were not nearly as effective as these systems are today. For instance, few, if any misfire detection systems of twenty, or even fifteen years ago had the benefit of feedback circuits that alerted an ECU that an ignition spark had, or had not been delivered, as the case may be. Moreover, since many ECU's sometimes had no way of knowing if an ignition spark had been delivered, these ECU's had no way of disabling injectors on misfiring cylinders, which could make it difficult to decide what was missing- fuel, or a spark.

Also, engine management systems of fifteen and twenty years ago used additional injectors known as "cold start" valves/injectors, whose function it was to inject additional raw fuel into the inlet manifold to improve combustion in cold engines by enriching the air/fuel mixture. This was done because ECU's of the time could not a) adjust injector pulse widths to increase fuelling, or b), deliver multiple injections per injection cycle to improve combustion.

Thus, if a cold start injector malfunctioned, two things could happen; it failed to inject additional fuel, or it continued to inject fuel even after it was commanded OFF by the ECU. Both conditions typically produced misfires across all cylinders, but if no additional fuel was injected, the misfires went away when the engine warmed up. If the cold start valve leaked or did not shut off, however, the misfires across all cylinders got progressively worse as the engine got progressively hotter.

So how did one diagnose misfires across all cylinders? Easy, really; but this "easy" had a caveat, this being the fact that both under and over fuelling produced excessive hydrocarbon loads, which meant that using an exhaust gas analyser to confirm a malfunctioning cold start valve could produce misleading, if not useless results. Therefore, one had to take a different approach.

In these designs, the engine coolant temperature was the triggering mechanism, because the non-heated oxygen sensor in use at the time could take several minutes to heat up the point where it could provide the ECU with useful information on the air/fuel mixture. Also, since bad wiring played a vastly greater role in almost all types of failures and malfunctions fifteen years ago than it does today, one could do several things, starting with-

We could list many other examples of why it was always better to make wiring issues the prime suspect in misfire diagnostics on old European cars, but limited space precludes this. Nonetheless, the point is this; removing, or bypassing existing wiring by running jumper wires to supply external power to suspect components almost invariably identified wiring issues as the root cause of most, if not all misfires on old European vehicles, which brings us to-

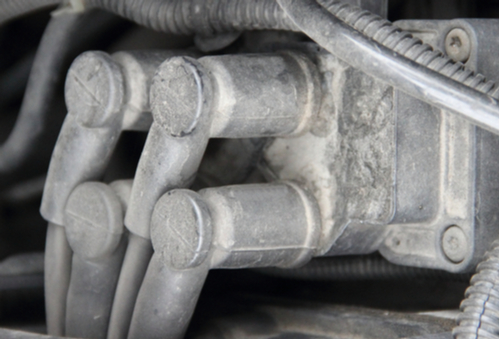

Image source:https://mechanicbase.com/wp-content/uploads/2019/07/car-misfire-spark-plugs-888x592.jpg

Spark plug failures have become rare events in recent years, and there are several very good reasons for this. These include, among others, the fact that modern spark plugs operate in "cleaner" environments, that air/fuel mixtures are more tightly controlled; that the propagation of the combustion flame is more even, and that secondary ignition currents are significantly higher than they used to be twenty years ago.

Then there is the fact that modern, small-diameter titanium and iridium electrodes don't suffer from spark erosion as easily as the soft copper and steel electrodes of older designs. Increased resistance against spark erosion does not result only in longer component life, but also in vastly improved heating of the plasma in the electrode gap by improved electrodes. For reference, it should be noted that the air/fuel mixture is not ignited by the actual spark; the mixture is ignited by the superheated ionised air (plasma) that is created in the air gap between the electrodes when the spark jumps across the gap.

So why is this important? It is important because it is much easier for an electrical current to exit a sharpened object (like a tapered modern spark plug electrode) than it is to exit a blunt object like the squared-off electrode of an old-style spark plug. We need not delve into the physics of this phenomenon here, beyond saying that since the current leaves a squared-off electrode on old-style plugs, the entire surface area of the electrode, but particularly the circumference of the electrode, is subjected to very high rates of spark erosion.

Spark erosion is the mechanism that causes the "rounding off" of old-style spark plug electrodes, and the more rounded the electrode becomes, the more difficult it becomes for the current to exit from the electrode. Moreover, the more rounded the electrode becomes, the bigger the gap grows, and the weaker the spark becomes. Eventually, the gap becomes so big that it becomes impossible for the current to leave the electrode, and it is at this point that the spark plug fails completely.

However, assuming that the correct spark plugs had been fitted, steadily increasing spark plug gaps also increase the resistance in secondary ignition circuits. This typically causes overheating of ignition coils because the coils take longer to ramp up to the point where the secondary current can jump across the increased electrode gap, but at the same time, the increased ramp-up times can delay delivery of the spark at high engine speeds. Delayed ignition sparks result in increased fuel consumption, reduced engine efficiency, and in many cases, catalytic converter failures.

In some cases, misfires caused by worn spark plugs can result in a chain of secondary events. For instance, increased resistance in secondary ignition circuits can overheat and damage ignition coil(s), which exacerbates an already weak spark. Also, weak sparks cause poor combustion, which can damage both oxygen sensors and catalytic converters, apart from causing excessive mechanical wear in cylinders when an overly rich mixtures remove lubricating films from cylinder walls. This, in turn, could lead not only to oil dilution but also to excessive pressure in the crankcase when combustion pressure leaks past worn rings, which in its turn, leads to excessive hydrocarbon loads entering the exhaust system via the PCV system.

In the real world, it is exceedingly rare to see the chain of events described above on modern engines, simply because modern spark plugs are vastly more efficient and durable than the spark plugs of twenty years ago. Thus, if you encounter misfires (both random and persistent, on all or just one cylinder) on an older European engine, your first diagnostic step should always be to check the condition of the spark plugs.

Even if the spark plugs appear to be in good condition (and are gapped correctly), we also recommend that you take the time to verify that the spark plugs are of the correct type and heat grade for that particular application. On old-style spark plugs, both the electrode gap and the heat grade are the single most important factors that determine the efficient long-term operation of the spark plugs, so pay particular attention to these things when you replace spark plugs.

One final thing about spark plugs in older European engines should be mentioned at this point. This is the fact that since misfire detection, ignition timing control, fuel control, and even exhaust scavenging were not nearly as advanced twenty years ago as they are today, the condition of spark plugs, and indeed, the condition of the ignition system as a whole, played a much larger role in engine operation than it does now.

Therefore, engine operation was much more sensitive even to minor wiring issues and small defects in ignition system components twenty years ago than it is now, mainly because ECU's of the time had far less capacity to compensate for small deviations from ideal engine and fuel management system protocols and operating parameters than the ECU's of today have, which leaves us with this-

While there are many more possible causes (such as engine vacuum leaks, poor quality fuel, and worn valve seats) of misfires on older European engines than the few pointers we have highlighted here, we nevertheless hope that this article has given you some new insights into the most common causes of misfires on older engines.

However, we are not suggesting that it is always possible to diagnose misfires on older engines without using proper diagnostic tools and a properly structured diagnostic strategy. What we are suggesting though, is that if you are aware of the principal differences between older and modern engines, it becomes possible to diagnose misfires on older engines faster, more efficiently, and more accurately than before. Because, well, older engines are different, and appreciating that fact can sometimes be extremely helpful.