The below article will help clear up some misconceptions that surround polyurethane bushings and rubber bushings. Specifically looking at the use of rubber bushings in standard and aftermarket applications compared to SuperPro polyurethane bushings.

Choosing the right polyurethane bushing brand is key, although poly bushings are perceived as superior each brand is different. SuperPro is one of the largest polyurethane bushing manufacturers in the world. Their bushings are specifically designed for each application and include proprietary design and material features, unique only to SuperPro. No polyurethane bushing is made equally, all normal design flaws generalised and associated with poly bushings are non-existent in SuperPro bushings.

Nearly all OEM manufacturers use rubber bushings. Rubber bushings came about in the 1950s and were seen as a marked improvement over the original metal components that required frequent maintenance and replacement due to extensive wear.

Rubber is easily accessible and lower in cost; many OE manufacturers prefer this to keep costs of production lower. Tooling is also cheaper for rubber bushings, making mass production a cost-effective solution for vehicle manufacturers. Rubber bushings under a load tend to flex, stretch, and compress. This can transfer into your steering, causing some difficulties with traction and creating oversteer or understeer.

Poly bushings are the relatively new kid on the block in comparison to the broader history of the automotive aftermarket industry.

Traditionally polyurethane has been associated with being a hard material, giving excessive NVH (Noise, vibration, and harshness). While the cost of buying some brands of poly bushes may be significantly more than an OEM rubber bush, if designed correctly for its application can save you money in the long run with a long service life and performance that doesn't degrade over time.

There are very few poly bushing manufacturers that create a decent bushing using material, engineering and manufacturing to create the perfect suspension bushing. That is why it is so important you find a suspension manufacturer that knows what they are doing.

Soft and Doey is the best description you can give a rubber bushing. If you drive any modern vehicle you will find that the car is wonderfully quiet and soft. Sadly, this doesn't transmit into having a vehicle that handles, accelerates and brakes well. The longevity of a rubber bushing is also a factor in ride quality as rubber bushings are built to fail, your ride quality will decrease over the service life of a vehicle.

Rubber bushings in aftermarket conditions perform at a lower standard and have a shorter lifespan when compared to SuperPro bushings. Mainly due to rubber breaking down easily when in contact with dirt, oil and water. The second issue is that rubber bushings are not designed to handle the amount of increased flex and torsion movement required when driving on track and off road.

SuperPro poly bushings offer a firm ride, yet still supply a comfortable driving experience through a responsive drive. Due to SuperPro bushing design features, there will be no increased noise, vibration or harshness (NVH). If you’re looking for better driving performance, direct steering, long service life, sharper and more responsive handling, then SuperPro poly bushings are the best solution.

Rubber bushings are produced on a massive scale, there is still a lot of engineering that goes into a rubber bushing. The main goal for rubber bushings is to keep the price down. But comparing it to a poly bushing OE bushes have to be mass produced without application specification as they are built to suit 99% of the world’s drivers. The main goal of an OE rubber bushing is to ensure maximum comfort, and this is done by creating an extremely soft bushing. The caveat to this is that the due to the rubber bushings material makeup and the way it is being manufactured, this soft engineering process actually acts as a negative. Causing a short life span, poor tyre wear, vehicle shudders and alignment issues.

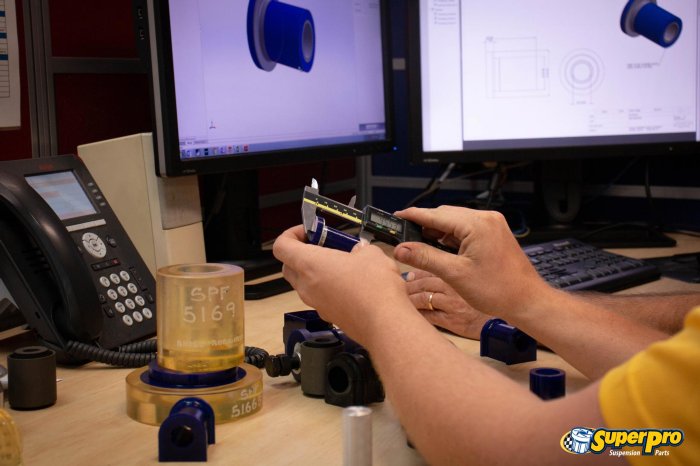

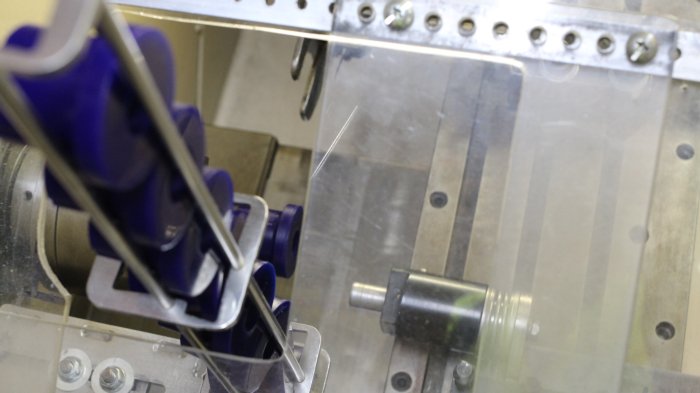

A lot more time, effort and thinking goes into a polyurethane bushing, especially a SuperPro poly bushing. Due to the complexity of material and also manufacturing process behind a SuperPro Poly bushing. The material design has to be perfect in order to supply a bushing which will perform in all conditions. SuperPro bushes are designed to fit an exact parameter of housing dimensions.

SuperPro basically takes an OE bushing and analyses it completely to see what they can do to make it the best possible suspension bushing. This includes adding design features for fitment, long service life and correct alignment issues not addressed by rubber bushings.

SuperPro poly bushes are designed and manufactured in Australia.

Rubber bushings are largely silent unless they are overloaded or have failed.

SuperPro poly bushings are designed to reduce any noise vibration and harshness (NVH) transmitted through the vehicle.