Experienced technicians know that when codes P0420/P0430 – Catalyst System Efficiency Below Threshold – appear on a vehicle, replacing the catalytic converter(s) does not always fix the problem. Inexperienced technicians on the other hand, may be tempted to take catalytic converter efficiency codes at face value and simply condemn and replace an inefficient catalytic converter out of hand, and are then surprised when the same codes reappear a few drive cycles later. This article will therefore take a closer look at what catalytic converters are, how they work, and why they fail, starting with this question-

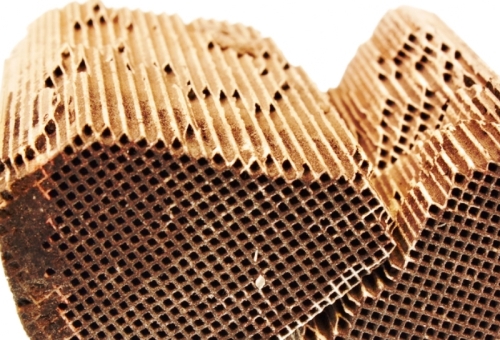

The image above shows detail of the lengthwise channels running through the uncoated clay substrate of a typical catalytic converter. While the actual shape of the channels may vary somewhat between different brands of converters, their purpose is the same across all applications, which is to allow exhaust gas to flow freely through the entire core of the converter.

In practice though, the channels greatly increase the surface area of the substrate, which is coated with a variety of precious metals that include platinum, rhodium, and palladium, these metals being the most common. Other catalysts include cerium, iron, manganese, and nickel, and by varying the relative concentrations of all possible catalysts, it is possible to design catalytic converters for particular applications, or to perform specific functions, such as the examples listed below-

Two-way catalytic converters

These converters perform two functions at the same time: highly toxic carbon monoxide is oxidised into relatively harmless carbon dioxide, and hydrocarbons are oxidised into carbon dioxide and water vapour. While this type of converter is still widely used on diesel engines in many parts of the world to reduce hydrocarbon and carbon monoxide levels, they are no longer used in the USA and Canada, because they cannot control emissions of NOx (oxides of nitrogen).

Three-way catalytic converters

In most jurisdictions in the world, including Canada and the USA, it is now a legal requirement to use three-way catalytic reduction of exhaust emissions, and particularly petrol exhaust emissions. These catalytic converter designs perform three functions simultaneously: NOx is reduced to oxygen and nitrogen, carbon monoxide is oxidised into carbon dioxide, and uncombusted hydrocarbons are oxidised into carbon dioxide and water vapour.

Diesel oxidation converters

This type of converter was designed specifically for use on diesel engines to address global legal requirements to reduce diesel emissions. In these converters, oxygen in the exhaust stream is used to oxidise carbon monoxide into carbon dioxide, and hydrocarbons (particularly uncombusted hydrocarbons) into water vapour and carbon dioxide. As a rule, these converters typically achieve efficiencies of 90% and sometimes more, and as an added bonus, they also remove the distinctive diesel smell and most visible solid particulate matter from diesel exhaust streams.

SCR catalytic converters

Note that catalytic converters on some diesel applications require a liquid reductant (most commonly a form of liquid urea known as DEF, or Diesel Exhaust Fluid) to work. These systems are known as SCR (Selective Catalytic Reduction) systems, and while they are highly efficient, especially when they are combined with a Diesel Particulate filter, the reductant injection systems on these designs are prone to failure, which we will cover in the next section.

While we need not delve into the complex chemical actions/reactions in catalytic converters that convert harmful substances into harmless substances, it is nevertheless worth noting that-

If all the above conditions are met, a typical catalytic converter will reduce emissions of hydrocarbons by up to 87%, carbon monoxide by up to about 85%, and oxides of nitrogen by roughly 62% - 65% during the average vehicles’ expected lifetime. However, things do not always work out this way and catalytic converters often operate at greatly reduced efficiencies, which begs this question-

Catalytic converters can and do fail for a variety reasons; reasons that do not always involve failures of the catalytic converter itself. Nonetheless, once a catalytic converter efficiency related trouble code appears, it is often too late to save the converter. In such cases, the catalytic converter has to be replaced, since unlike diesel particulate filters, catalytic converters can often not be regenerated to restore their efficiency.

Therefore, inexperienced mechanics should take note that it is futile to replace a hugely expensive catalytic converter if the underlying problems that caused the converter to fail are not addressed and corrected before returning the vehicle to a customer. Inexperienced mechanics should also keep mind the fact that no ECU can monitor the efficiency of a catalytic converter directly; it can only infer an efficiency value by comparing data from the oxygen or air/fuel ratio sensors that are located before and after a converter.

This fact adds an additional layer of complexity to diagnosing catalytic converter issues, but before we get ahead of ourselves, let us looks at some common issues that can cause catalytic converters to fail, or operate below minimum allowable efficiency thresholds-

This image shows a defective fuel injector squirting a stream of fuel into a cylinder, instead atomising the fuel in a funnel-shaped pattern. In cases like this, the fuel cannot combust cleanly and some unburnt fuel might enter the catalytic converter. If the converter is at operating temperature, the uncombusted fuel could ignite, which can cause the converter core to melt in less than ten seconds if the faulty injector continues to inject un-atomised fuel.

Other examples of over fuelling include marginally defective injectors that inject deformed spray patterns, injectors that leak between multiple injection events, or excessively high fuel pressures during some or all points in an engine’s operating range. Depending on the severity of the problem, the uncombusted hydrocarbon load can increase to the point where the catalysts are coated with soot, which causes catalytic converters to work at reduced efficiencies- if they work at all.

One other cause of reduced catalytic efficiency or even catalytic converter failure relates to ignition system issues. Weak sparks or missed multi-sparking events can also cause inefficient combustion, which generally has the same effect on catalytic converters as over fuelling. It should be noted though that almost all ECU’s have the ability to disable fuel injectors on cylinders that do not receive ignition sparks to protect the catalytic converter(s) on the vehicle.

The diagnostic process for fuelling issues must include investigating all the usual suspects because some fuel related issues will not necessarily always set trouble codes- marginally leaking injectors being one example. Nonetheless, the diagnostic process would begin by extracting all active and pending codes, which must be recorded along their freeze frame data if such data is available. This step should also include obtaining fuel trim values, because this information is as much a diagnostic aid as it is a symptom. Then, begin resolving codes in the order in which they were set, but keep this cautionary tale in mind-

This writer once spent two full days chasing the cause of excessively high negative fuel trim values in an attempt to diagnose the root cause of a catalytic converter meltdown on an Audi A6. Unbeknownst to this writer however, the owner of the vehicle had replaced the spark plugs with totally unsuitable plugs a few weeks prior, which was what caused the poor combustion, and hence, the high negative fuel trim values. There were no active codes on this Audi A6, but had I used an exhaust gas analyser at the start, or paid more attention to the pronounced sluggish performance of the vehicle, I would have discovered the cause of the overly rich air/fuel mixture within minutes- instead of after two days.

The point of all of this is that when fuelling issues are suspected to be the cause of a catalytic converter failure, all possible causes of fuelling issues and poor combustion must be investigated, including the condition and suitability of the spark plugs.

Excessive oil consumption spells death to any catalytic converter, because the partially combusted oil forms a layer of carbon on the catalytic surface, which translates into the converter not being able to oxidise harmful substances in the exhaust stream into less harmful substances.

As with fuelling issues, all possible causes of excessive oil consumption must be investigated. Leaking turbocharger seals (if turbo/supercharged), excessive piston ring and cylinder bore wear, hardened valve stem seals, and defective/faulty PCV systems can, and do, contribute to catalytic converter failures, and sometimes on a fairly regular basis, at that.

Moreover, using engine oil of the incorrect type, formulation, grade, or viscosity can also cause or contribute to catalytic converter failures. If any doubt exists about the suitability of the oil in an engine, take a sample and have it professionally analysed before replacing the catalytic converter. Doing it the other way round could cause the premature failure of the replacement converter.

Inexperienced mechanics should note however that some makes and models naturally use a lot of oil. These include almost all turbocharged (and some naturally aspirated) BMW, AUDI, Mercedes, and VW models; in these cases, there is nothing to be done about the heavy oil consumption other than advising owners of these vehicles that regular catalytic converter replacements should be considered as being part of the cost of owning such a vehicle.

![]()

The image above shows the effect of silicone contamination on an oxygen sensor. The issue here is not the weird colour of the sensor- the issue is the fact that silicone deposits on the sensing elements of oxygen and air/fuel ratio sensors destroy these sensor’s sensitivity, with the result that engine management systems then use default fuel delivery strategies, which almost always translate into rich air/fuel mixtures. In addition, silicone deposits can also coat the catalysts in catalytic converters, which results in reduced catalytic efficiency, or sometimes, in outright failure of the converter.

Finding the source of silicone contamination is not always easy, since it could be in gasket sealer the vehicle owner had used to fix a fluid leak, or, it could be in aftermarket oil and fuel additives the vehicle owner may be using. Regardless of the source of silicone in an engine, once the catalytic converters’ efficiency falls below a critical minimum threshold (which is when codes P0420/P0430 are set), the catalytic converter many be beyond saving, anyway. However, unless the source of silicone contamination is found and corrected/eliminated, the replacement converter is almost certain to fail as well, so be aware that correcting this issue might involve reversing all DIY repairs that involve unsuitable gasket sealers, and/ or draining and replacing the fuel and/or engine oil.

Selective catalytic reduction systems work on the basis of very precisely metered amounts of reductant being injected into the exhaust stream at precisely calculated times. Therefore, too much or too little reductant being injected can reduce catalytic converter efficiencies, since the liquid reductant is the main oxidising agent.

However, gross defects or malfunctions in the reductant injection system that are deemed by the ECU to be likely to damage the catalytic converter, or to cause emissions to be raised to unacceptably high levels are more likely to produce failsafe or limp modes than the failure of a catalytic converter. Typical failures that would produce a limp mode, or no-start condition in some cases, include failures or malfunctions of the reductant injection pump, blockages of any feed line in the reduction system (including the injection nozzle), or simply running out of reductant.

It should be borne in mind however, that liquid reductant injection systems are monitored and controlled in real time by a host of dedicated sensors, and malfunctions/failures in one or more of these sensors can cause the injection system to stop working, which often results in a no-start condition or a limp mode. Nonetheless, failures in reductant injection system sensors produce dedicated fault codes, all of which must be investigated and resolved in their order of setting whenever a catalytic converter issue is diagnosed on a SCR system.

Mechanical damage such as impacts by road debris can sometimes cause the converter’s core to fracture, which renders the converter useless and ineffective. The same is true for a converter that had overheated, which is usually indicated by a measure of discolouration of the outer shell, which brings us to-

Limited space precludes a comprehensive discussion of all the PID’s that can be used to diagnose the underlying causes of catalytic converter issues, but the few tips and tricks listed in this section should help you diagnose catalytic converter issues quicker and more reliably-

Don’t read too much into exhaust gas temperatures

In this context, exhaust gas temperatures refers to the temperature of the exhaust gas at the inlet and outlet points of the converter. There was a time when valid inferences could be drawn about the health of a catalytic converter purely based either on large temperature differences at the inlet and outlet points, or, on the fact that the two temperatures were the same, or close to the same.

However, most modern engines are so efficient that in some cases, the catalytic converters’ inlet and outlet temperatures do not differ by more than a few degrees, even when the converter is working at maximum efficiency. The better way to determine catalytic converter efficiency in these cases is to obtain live data from the upstream and downstream oxygen or air/fuel ratio sensors; if the data from the upstream sensor fluctuates rapidly and consistently between rich and lean but the downstream sensor’s data is steady at around the midpoint, the converter is working fine. Bear in mind though that both oxygen and air/fuel ratio sensors lose some sensitivity over time, so use your best judgment when comparing live data from these sensors.

However, this comparison should be done at different throttle openings and only while the engine is operating in closed loop, but even so, the downstream sensor’s live data should never match that of the upstream sensor; if it does, the converter is defective. Of course, this assumes that all relevant sensors are working properly, and that fuel trim values are within acceptable limits.

Make sure all relevant sensors are working properly

These include oxygen or air/fuel ratio sensors (and their heater control circuits), exhaust gas temperature sensors, NOx sensors (where fitted), and exhaust gas backpressure sensors. False, inaccurate, or implausible data from any of these sensors could affect fuel trims so check for sensor codes and resolve them before condemning a catalytic converter out of hand.

Confirm exhaust backpressure independently

Not all causes of catalytic converter issues involve excessive exhaust backpressure, but some do. Therefore, if a clogged converted is suspected, screw a correctly graduated pressure gauge into the upstream oxygen sensor’s location, and physically check the exhaust pressure at a range of engine speeds, and compare your findings with the value(s) specified by the manufacturer. This way, you can be sure that you are measuring exhaust backpressure caused by the catalytic converter, and not exhaust backpressure caused by a restriction such a clogged muffler or some other exhaust component.

From the above it should be obvious that diagnosing the causes of catalytic converter issues/failures is not an exact science, but with some common sense, some analytical thinking, and a sound knowledge of emission control technologies it is possible to take the pain out of finding and repairing the root cause(s) of catalytic converter issues fairly easily.

The battle is halfway won if you can recognise the codes that can potentially affect the efficiency of a catalytic converter. Simply resolve those codes, and complete a few drive cycles after each step in the diagnostic/repair process to see if all the monitors run and complete successfully- if they do, you might just have saved your customer a ton of money.