In Part 1 of this two-part article, we discussed the importance of performing post-work diagnostic scans on new and late-model Nissan vehicles to ensure that all fault codes have been resolved definitively. This step is particularly important after completing work or repairs on ADAS systems, which have undergone substantial improvements in recent years.

Now, in Part 2, we will discuss some specific things to look out for when servicing or repairing ADAS systems on modern Nissan vehicles. In some cases, repair and calibration procedures have changed and the old ways of doing things on Nissan vehicles do not work anymore, but before we get to specifics, we need to mention the fact that the best strategy to avoid personal liability when working on Nissan ADAS systems is to-

Anecdotal evidence is suggesting that independent workshops are seeing growing numbers of late-model Nissan vehicles with faulty or inoperable ADAS systems. Therefore, and as with all other types of faults, a comprehensive diagnostic scan must be performed (preferably with Nissan’s CONSULT III software) and the scan report must be attached to the work order. Moreover, all recommended repairs and suggested parts replacements must be recorded as well to avoid “since you did this, that, or the other thing” situations in the future.

The next step falls mainly to service writers. This step involves explaining all proposed repairs to the customer, who can then make an informed decision on which repairs to authorise or not, as the case may be but to avoid misunderstandings, the customer’s instructions must be included in the work order in unambiguous terms. This should be standard practice in all independent workshops, but sadly, this is not the case, which could potentially leave many independent workshops open to liability claims soon because-

We all know that the Australian Design Rules (ADRs) are sometimes slow to reflect or accommodate new technologies on light vehicles, but when the Design Rules do change, most of us are often unaware not only of the changes but also of what such changes mean for us as mechanics and technicians in the independent repair industry.

There are many examples of this that we could list here, but let’s look at one particular change in the US market that could potentially catch us unaware locally. This change involves the “Advanced Driver Assistance System Repair Act”, which was submitted to the Illinois State Congress early in 2022. Although this ACT does not appear to be in force yet, two provisions of this ACT have the following aims, which we will quote verbatim-

1) “An automotive glass company or repair facility conducting a scan or recalibration shall recalibrate the advanced driver assistance system to meet or exceed the manufacturer's procedures or specifications.” (Italics and bolding added for emphasis)

2) “If a recalibration was not performed or not completed successfully, the automotive glass company or repair facility shall inform the consumer electronically or in writing that the recalibration was not successful or was not performed and that the vehicle should be taken to a vehicle manufacturer's certified dealership, a qualified automobile glass company, or a repair facility capable of performing the recalibration of an advanced driver assistance system that meets or exceeds the manufacturer's specifications.” (Italics and bolding added for emphasis)

This ACT says many other things besides the above, but why do we even mention this ACT given that it is designed to operate in a jurisdiction on the other side of the world? You may well ask because we know that many ADRs are virtual carbon copies of rules or laws that first saw the light of day in foreign automotive markets or jurisdictions. This is not necessarily a bad thing, but the point is this- if in the (likely) event that this, or similar legislation is ever incorporated into one or more ADRs, every independent workshop in Australia will be held liable if at least the two provisions quoted above are violated. This is also not necessarily a bad thing, but don’t see this as a scare tactic: this is just a heads-up that we soon might have to rethink our collective approach to servicing, repairing, or calibrating ADAS systems on Nissan vehicles, which brings us to-

Although the sonar sensors on Nissan vehicles are generally robust and fairly resistant to the effects of environmental factors like large temperature fluctuations, these sensors are not indestructible and they do fail for reasons other than accident damage. However, with that said, how often do we test the operation of sonar sensors on Nissans (and other vehicles) as part of a routine vehicle inspection? If the truth were told, we only inspect or test sonar sensors when we encounter reported faults in the Park Assist system or other ADAS systems that use sonar sensors to work.

Fortunately, there are now several easy ways to test the operation of sonar sensors available, one of which is the hand-held wand that is available from PicoScope® that is shown below-

Image source: https://automotivetechinfo.com/wp-content/uploads/2022/02/Ultrasonic-Parking-Sensor-Detector.jpg

This particular sensor tester runs off PicoScope® oscilloscope software, and it tests or captures the actual signal a sonar sensor produces when an ADAS system that uses sonar sensors is activated, unlike other test methods that merely show whether or not a sonar sensor works or not.

So when this tester is connected to an oscilloscope, it becomes easy to test all the sensors on the vehicle and then compare the waveforms to identify a defective or malfunctioning sensor. The image below shows a known-good waveform of a sonar signal taken from the Park Assist system on a late-model Nissan passenger vehicle-

Image source: https://automotivetechinfo.com/wp-content/uploads/2022/02/Picoscope-Sonar-Sensor-Waveform.jpg

Note that the object of this test is not to capture absolute values. Although capturing sonar waveforms to obtain absolute signal values from all the sonar sensors on a vehicle is not necessarily a bad thing, all the waveforms from sonar sensors should be similar if not always identical, so if the signal from one or more sensors differs from the others substantially, you have found a defective or malfunctioning sonar sensor(s).

Note that Nissan provides additional information on why sonar sensors may not work in NTB21-043, which applies to all Nissan vehicles that are equipped with sonar sensors. This bulletin lists some of the operating parameters of sonar sensors fitted to Nissan vehicles, so be sure to consult this bulletin if you encounter sonar sensor failures. It could be that a customer expects too much from the Park Assist and other systems on their vehicle, which brings us to something entirely new to some of us on some ADAS systems in Nisan vehicles, this being –

Forward-looking optical cameras have undergone huge changes and developments in recent years and in some cases, these developments have happened so quickly that revised calibration procedures are not included in even the latest repair manuals.

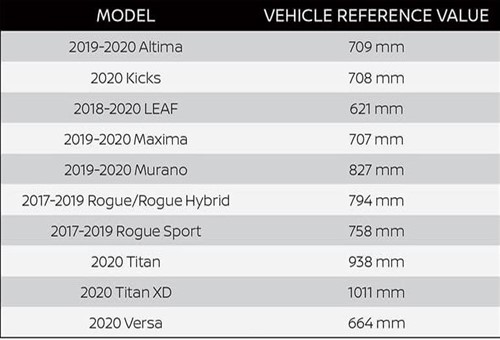

Moreover, while some high-end generic scan tools are capable of performing some calibration functions on forward-looking optical cameras on some older Nissan vehicles, complete camera calibrations on late-model vehicles can now only be performed with Nissan's CONSULT III software. Consider the table below-

This table is taken from NTB20-066, which describes the revised camera calibration procedure for the Nissan models listed in the TSB. While it is not entirely clear from this TSB what the listed Vehicle Reference Values mean, the point is that these values must be entered into the CONSULT software to complete a camera calibration procedure. It also means that independent workshops that do not have access to Nissan’s CONSULT software cannot perform calibrations of the Lane Keep Assist cameras on the vehicles listed in the referenced TSB.

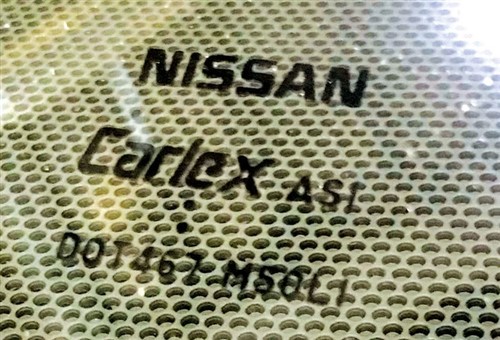

Nonetheless, even if you have access to CONSULT software and suitable hardware, it could happen that camera calibrations fail or abort repeatedly. This could happen for several reasons, but one common reason is that the windscreen could be an aftermarket replacement part. Consider the image below-

Image source: https://automotivetechinfo.com/wp-content/uploads/2022/02/Nissan-OE-Glass.jpg

The markings on this windscreen identify the glass as OEM-approved, but in practice, not all aftermarket windscreens are bad. However, the problem with aftermarket windscreens is that in many cases, the glass has refractive qualities that do not meet OEM specifications. Therefore, if a vehicle is fitted with such a windscreen, it might be near impossible to calibrate the forward-looking cameras correctly, if at all. Below is an official statement by Nissan North America (quoted verbatim) regarding aftermarket windscreens-

“…Genuine Nissan auto glass plays an important role in the safety of the vehicle by providing structural rigidity, ocular clarity, and integration with advanced vehicle technology. In addition, glass can play a critical role in noise dampening, UV protection, and general occupant comfort and safety. For these reasons, Nissan North America DOES NOT support the use of aftermarket or recycled glass in a repair situation. If an aftermarket windshield is unavoidable in a repair situation, please be sure it meets the same specifications and [of] similar quality to the OEM windshield being replaced.”

The last sentence in this statement is the tricky part because we can never be sure whether any given aftermarket windscreen will or will not cause issues with camera calibrations. However, the conditions that allow forward-looking optical camera calibrations to complete successfully on new and late-model Nissan vehicles are currently so precisely defined that when camera calibrations fail repeatedly, there is a more than even chance that the windscreen’s refractive qualities do not conform to OEM specifications.

So, when you encounter repeated calibration failures, we strongly suggest that you check the windscreen markings to determine whether (or not, as the case may be) the affected vehicle has an OEM or OEM-equivalent windscreen. If it does not have an OEM-approved windscreen and you cannot calibrate the forward-looking cameras, the only remedy is to have the windscreen replaced with an OEM or OEM-equivalent part, which leaves us with this-

We hope that this article has made you aware of a) the changes in the current ADAS landscape in modern Nissan vehicles and b) the importance of searching for sources of service and repair information like TSBs before attempting to service or repair any ADAS system(s) on any new or late model Nissan vehicle.

One other complicating factor is that Nissan has been fitting Secure Gateway Modules to progressively more new models in recent years not only to protect car owners’ personal information but also to prevent unauthorised access to and programming of control modules- including modules that manage critical ADAS systems.

It is also worth pointing out that while it is possible to unlock Secure Gateway Modules with some high-end generic scan tools, some ADAS programming or calibrations can only be performed with Nissan's CONSULT software and suitable hardware. In practice, this means that we need to be aware of the limitations of the tools we own or have available before we attempt to access ADAS systems on new or late-model Nissan products to prevent not only wasting time but also potential damage to a vehicle's electrical system.