To give you a deeper look at what goes into the research and development stage, the Bendix team headed down to their Product Engineering Centre in Ballarat, Victoria and spoke to the brains of the operation, Bendix’s Head of Engineering, Andrew French who we interviewed in the 'Ask me Anything' Podcast Series earlier this year.

Research & Development

The first phase of the process is developing the compounds that make up each brake pad. Each compound is developed according to various customer needs, from those who simply drive their cars around town, to more extreme use on the race track.

Their formulations are developed right in their Product Engineering Centre, where the brake pads are then made and tested. The whole process happens in-house thanks to a wide variety of development, mixing, pressing, manufacturing and testing equipment.

Both international and in-house procedures and guidelines are used to validate their materials and ensure that their brake pads are safe once installed. They then undergo extensive lab testing both on hub dynamometers and on vehicles.

The range of Bendix brake pads are catered to suit a wide range of driving styles, and of course, each brake pad type is developed differently to cater for different driving needs.

General CT

The General CT is the bedrock of Bendix’s brake pad range. But they aren’t just your standard OEM spec replacement brake pad. They provide improved quietness and smoothness across a wide range of operating conditions, whilst also delivering low dust and consistent pedal fee.

One feature that helps the General CT stand out of the crowd is their specially developed Blue Titanium Stripe. This feature acts as an intermediate layer between the brake pad and the rotor and does away with the standard bedding-in process, providing maximum friction and pedal feel right out of the box.

Noise, cleanliness and wear are all tested in-house using dynamometers. These tests are then validating with extensive in-field testing.

4WD/SUV

Their 4WD/SUV brake pads cater for the avid adventurer, providing rugged and reliable performance in the most extreme off-road conditions. But they also understand, that most off-roaders also spend a lot of their time driving in urban conditions, so their 4WD/SUV brake pads deliver outstanding

braking performance both on and off the road.

To formulate their 4WD/SUV brake pads, they have taken General CT type manners and combined that with Heavy Duty performance for when its time to hit the rough stuff. Ceramic bases are used for their 4WD/SUV brake pads. There’s a wide variety of 4WD type bases available to suit a wide range of 4WDs, so it’s just a matter of selecting the appropriate base for the appropriate vehicle. The result is a brake pad that offers low dust, low noise and effective performance.

Heavy Duty

Their Heavy Duty brake pads cater for vans, trucks, utes and other load-carrying vehicles. These workhorses operate under higher load and temperatures compared to your average road car, and thus have very specific needs when it comes to brakes.

The Heavy Duty brake pad is specially formulated to withstand the high temperatures and loads that these workhorses operate under whilst still providing consistent performance.

Ceramic materials wear excessively in high heat applications, so a material with a high metallic content was needed for the Heavy Duty brake pad. This ensures that performance and wear life is maintained under heavy load conditions.

The Heavy Duty isn’t just for trade vehicles either. The Heavy Duty brake pad is also available for most cars for when you need just that amount of performance over the GCT, such as when you’re towing a trailer.

Euro+

It can be tricky finding the right parts for European cars, and this includes brake pads. Luckily, the Bendix Euro+ brake pads have been developed to meet and exceed OEM and European Union’s ECE Regulation 90 rules.

ECE Regulation 90 rules stipulate that their brake pads need a plus or minus 15% performance against that of the OEM item.

To cater for such a wide range of vehicles, Bendix selects the right formulations to suit each vehicle. On top of that, they include all the hardware, such as sensors, required for that specific vehicle to ensure easy, stress-free installation. Their sensors are based on OEM designs and tested for correct fitment for each and every application.

Compared to traditional European brake pads, which are known for higher dust levels, their Euro+ formula provides low dust, similar to their GCT.

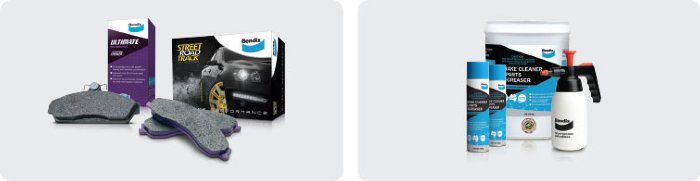

Ultimate and Street Road Track

Developed especially for the car enthusiast, Bendix Ultimate and Street Road Track brake pads are perfect for those that like to push their cars hard. Developed specifically for performance applications, they maintain high levels of performance across all conditions and resist brake fade at

higher temperatures.

Because of this, testing for their high performance brake pads is different to the testing that their GCT brake pads see. Along with standard strength testing, their Ultimate and SRT brake pads are tested under track conditions, both on the dyno and on the track.

Brake components for Commercial Vehicles

Bendix also manufactures brake pads, brake shoe kits and brake linings for commercial vehicles such as long haul trucks, trailers and buses. To formulate these products, they have applied their learnings from their passenger car brake pad research and development and added material for improved strength and wear life to account for the kind of use that these commercial vehicles see.

These commercial items see dyno testing and extensive field testing with fleet operators around Australia. This gives Bendix feedback on a variety of real world conditions.

Their research and development trickles down into our other brake products and accessories such as their Ceramasil Brake Lubricant, Brake cleaner, Shims, Sensors and Clips. All of their brake products are developed and tested for each and every application to ensure long lasting, reliable performance.

To find your nearest Bendix stockist, visit www.bendix.com.au/stockists

To follow us on Facebook for the latest updates and news, visit www.facebook.com/bendixworkshop