While the imminent implementation of the Mandatory Data Sharing Law will make it possible for independent repairers to service and repair vehicles that are covered by factory warranties, the truth is that the ability to work on new vehicles comes with major downsides that many independent repairers may be unprepared for. To be sure, none of these obstacles is insurmountable, but it is as well to be aware of them, and in this article, we will discuss what most independent repairers can expect when the Law is implemented, starting with the fact that-

Apart from the facts that a) OEM-level scan tools are often required to perform programming and some relearning procedures on new vehicles, and b), that OEM-level scan tools are typically very expensive, the biggest problem with these scan tools is that their software is often incomplete. Not only incomplete, but sometimes, OEM-level scan tools' software lack details such as updates, or worse, revised repair procedures. We can list many examples of incomplete OEM software here, but let us look at an actual case study instead, since this case clearly illustrates the point that relying on just one source of service and/or repair information is never a good idea. Thus, let us look at the case of the-

During August of 2020, this writer received a 2014 Toyota Highlander hybrid in his workshop. The customer originally requested that we perform an HV battery inspection, but later called to ask that we also check the wheel alignment and especially the toe-in because (according to the customer), the steering response was not as "sharp" as it used to be.

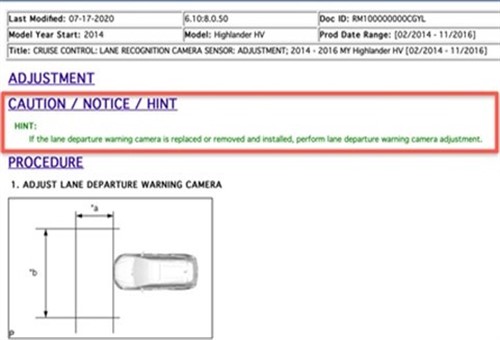

Since the wheel alignment tech was new to this particular Highlander model, which was equipped with all the latest driver-assist systems, he researched the correct wheel alignment settings on an aftermarket resource that claimed (as do many others) to obtain all their service information directly from the OEM. Long story short though, this resource listed the following requirement- “If the lane departure warning camera is replaced or removed and installed, or the toe-in is adjusted, perform lane departure warning camera adjustment/recalibration”. (Italics and bolding added for emphasis)

The image above is a partial screenshot of the aftermarket resource’s page for the particular Highlander model, and while the requirement to perform a lane departure warning camera calibration did not present problem in itself, the problem was that we had not done this procedure on this particular model before. Therefore, to avoid short-changing ourselves or overcharging the customer, we contacted the local Toyota dealership to obtain details on how long calibrating this camera would take.

It turned out that the dealership was rather surprised that we would ask such a thing because, as far as they were aware recalibration of the lane departure warning camera was no longer required after a simple wheel alignment on Highlander models. According to the dealership, the only time this was required was after the vehicle had been in a frontal collision, or after the camera had been removed for whatever reason. The dealership flatly stated that our information was outdated, and referred us to an official Toyota document that proved our information was indeed outdated.

This document, titled Document ID: RM100000000CGYL, version 6.10:8.0.50, was released by Toyota’s Technical Information Service on July 17th 2020, and it made no mention of the requirement to recalibrate the lane departure warning camera after a wheel alignment on Toyota Highlander models. Since we had enjoyed a good relationship with this particular Toyota dealership for many years we were not inclined to disregard their advice or opinion, but just to make double sure that our aftermarket source was wrong, we searched for the same information on three of our other aftermarket resources. It turned out that only one aftermarket source had updated their information to include the latest release from Toyota, so what does this mean for us as independent technicians?

It means simply this; we cannot rely on aftermarket sources of service and repair information as much as we used to. To prove this to ourselves we updated our Toyota TechStream scanner, which we had not done in about six weeks or so, and there it was; the language about performing a lane departure warning camera recalibration after a wheel alignment* on this particular Highlander model was no longer present.

* In the end, we traced the problem of the poor steering response to marginally under-inflated tyres on rims that were slightly wider than standard. Adjusting the tyre pressures restored the “sharpness” of the vehicle’s steering response.

This experience (again) taught us the short, sharp lesson to keep our equipment updated because even if we had relied on our (un-updated) TechStream tool, we would have performed an unnecessary calibration on a safety-critical ADAS system. In our defence, such as it is, we persuaded ourselves that we could not possibly have foreseen this critical update occurring in the period between the 20th of July, and the end of August when we had the vehicle in our care.

We also argued that nobody can be expected to keep up with the hundreds of updates to vehicle software that are released by OEM manufacturers almost daily, but if we are to start working on new vehicles that are covered by factory warranties, that is exactly what we have to do, which brings to-

We certainly will not need to purchase an OEM scan tool for every brand of vehicle that could potentially roll through our doors, because a single pass-through device that conforms to the SAE J2534 standard can communicate with all OBD II compliant vehicles via a laptop computer, regardless of the communications protocol or standard used by the OEM.

However, to make J2534 pass-through devices work, we will need to purchase OEM-level diagnostic and calibration software, so it might be more accurate to refer to the limitations of OEM software, as opposed to the limitations of OEM diagnostic hardware. What limitations, you may ask?

You may well ask because while most of us might have thought that dealer-level software will always work, the fact is that in many cases, the diagnostic software you buy will rarely be 100% complete, or up to date. This is not through any evil intent on the part of either vehicle or scan tool manufacturers: it is a simple matter of a) technologies that develop faster than everybody can keep up with, and b), the exorbitant cost of licensing software from the car manufacturers.

According to sources in the scan tool manufacturing industry, licensing software from a vehicle manufacturer for a single vehicle model range for as little as a year can run to as much as US$ 200 000 or more, and that amount typically excludes the inclusion of software updates, patches, and fixes as they become available. As a result, most OEM-software suites are typically only about 90% (or so) complete when they are brought to market.

Of course, the high initial capital investment that third-part purveyors of diagnostic software need to recover as soon as possible means that software is a) marketed extremely aggressively, and b), often prematurely. Moreover, in most cases, users can only access updates, patches, and fixes through a two-payment subscription system; one (typically recurring payment) to guarantee 24/7 access to technical support for the software, and another (typically once-off) payment to get access to said updates, patches, and fixes.

So where does leave most independent repairers? Put bluntly, it leaves many independent repairers up a rocky creek without a paddle, because there is no reasonable way to avoid the costs associated with obtaining OEM-level repair and service information. In the example of the Toyota Highlander we cited elsewhere, the costs of updating our TechStream software came to 649 US dollars.

Moreover, while we were very fortunate that the local Toyota dealership gave us the required information for nothing, we would have been out of pocket by another 38 US dollars for 24 hours’ access to the aftermarket site that did have the updated information. Luckily, though, we did not download the revised service information so we missed that payment, which incidentally, had to be in US dollars because that resource is located in the US.

On the positive side, it is almost certain that when the Mandatory Data Sharing Law is implemented, all payments for OEM-level service information will be in local currency. However, there is a very good chance that local payments will be based on US dollar rates, so the exchange rate might still hurt us, but how much we’ll be hurting remains to be seen, which brings us to-

If you were thinking that having access, albeit paid access, to OEM-level service information would make it easier to work on new vehicles, you would be right, but you’d be right only up to a point. One other obstacle, and a major one at that, involves the way some systems like telematics and most ADAS features are protected on most vehicles made after 2018.

You may have encountered so-called “Secure Gateway Modules” on pre-2018 vehicles before, and a high-end generic scan tool may even have allowed you some access to one or more serial communications systems or control modules. However, the principal purpose of secure gateway modules on post-2018 vehicles is to prevent all unauthorised access to ADAS, telematics, and some other safety-critical systems. The only way to gain access to these systems for diagnostic and reprogramming purposes is to enter a specific and often, a single-use security code that can only be had from resources/vendors that are licensed by OEM manufacturers in exchange for a rather hefty subscription.

In the US market, independent repairers currently have access to two such resources, one of which resulted from a string of thefts (by hacking) of various Chrysler vehicles. Because of these thefts, FCA (Fiat Chrysler Automobiles) negotiated an arrangement with a company called AutoAuth to provide security codes and other secured information to independent repairers to gain access to secure gateway modules on many post-2018 vehicles. Signing up for this access involves a lengthy process to link specific scan tools to the service, but the upside is that up to 100 tools per workshop can be linked.

One other similar service is provided by a division of the National Automotive Service Task Force* known as the Secure Data Release Model (SDRM) that requires users to register as VSPs (Registry Vehicle Security Professionals). Signing up for this service is considerably more expensive, complicated, and lengthy than signing up for the AutoAuth service since the process includes comprehensive background checks. However, the upside is that the SDRM service provides all security information, includingkey codes, security system PINs, immobilizer reset events, radio security codes, and any other types of security-related information for at least 17 vehicle makes, which collectively, covers about 95% of the US domestic market.

*Note that while users around the world could access the National Automotive Service Task Force website freely, access now seems to be restricted only to users in the US market. Access will almost certainly be granted to Australian users when the Mandatory Data Sharing Law becomes operative, but since this is not certain, or known when such access may be granted, Australian users may be forced to use A VPN to gain access. Thus, until this issue is resolved, independent repairers in Australia seem to be limited to the services offered by AutoAuth.

There is another problem worth discussing, and this issue includes the fact that many, if not most OEM manufacturers prohibit their dealers in the US market from selling some categories of parts to independent repairers unless the repairer can show proof of registration as vehicle security professional. At the moment, there is no telling if (and, how) this prohibition will apply to us as Australian independent repairers, but as a practical matter, the prohibition on parts in the US market includes things like transmission and even some brake system parts.

Which parts independent repairers are prohibited from buying without the requisite registration(s) vary between manufacturers, but the details hardly matter. The point is that unless we, as independent repairers, are prepared to register as vehicle security professionals and pay the required subscription fee, we are effectively excluded from the benefits and advantages the Mandatory Data Sharing Law is designed to give us, which leaves us with this-

On the face of it, it might seem like the Mandatory Data Sharing Law will present us with more problems than it solves, but this may be an overly negative view. To be sure, many of us, and especially mobile mechanics who have to pay their own way in terms of maintaining diagnostic equipment and software, are faced with costs we may not have planned for, but the upside is that as an industry, we will be on an equal footing with dealerships. Being able to compete with dealerships on a proverbial level playing field is no small thing, and although the initial costs and learning curves may be steep, they are not prohibitively so, or at least, not for the majority of independent workshops.

Nonetheless, the art of securing critical systems on modern vehicles against hacking and/or unauthorised repairs has evolved into an exact science. Therefore, if we want to access or share in the vast pool of business that warranty-covered repairs represent, we need to pay our money, and to sign up for whatever is required to give us access to the information we need to compete with dealerships. Are you up for the challenge?