This writer was recently privy to a discussion between two of his longtime acquaintances (and sometime) customers about engine oil. One party held the opinion that all engine oils are the same no matter the brand, while the other party maintained that engine oil never wears out, and that just topping off the oil level every now and then was sufficient to prevent an engine from seizing or blowing up.

Off course, neither party could be more wrong, but since discretion is the better part of valour, this writer thought it best not to remind either party that he had replaced the engines in both their vehicles after both engines failed for the same reason. In both cases, the engines failed as a result of poor lubrication caused by severe degradation of the oil in them. However, this writer is a strong believer in the maxim that some people are happier when they are not being confused with facts, so he left the combatants to confuse each other with misinformation, misconceptions, and outdated ideas about the properties, characteristics, and limitations of engine oil.

Unfortunately, we cannot clear up all the current misconceptions about engine oil in an article of this nature but suffice it to say that lubrication technology has always lagged behind mechanical advances and innovations in internal combustion engines. Smaller operating clearances between rotating and sliding parts, high combustion pressures, extreme heat, and small oil volumes in modern engines place extreme demands on even the most advanced oil formulations, and it was only after the recent introduction of GF-6-compliant oil formulations that the capability engine oil can be said to have caught up with the demands of modern engine technologies.

Having said that though, even the most advanced GF-6 oil formulations are based on mineral or synthetic base oils that have little to no lubricating properties. Therefore, meaning all of any given modern oil formulation’s lubricity derives from the “package” of additives that a) improve the lubricity of base oils, and b) suppress some of the undesirable properties of base oils. Thus, in this article, we will discuss the role and importance of additives in modern oil formulations in terms of what they are, and what they do. Let us start by asking the following question-

Harking back to the discussion between this writer’s two acquaintances, it must be said that it does not matter if one mixes different oil brands and formulations in an engine, or merely keeps topping off the oil level with new oil of the same brand and/or formulation over an extended period. As a practical matter, the effects of both practices are all bad, but the two most pertinent of these effects are that-

In the first case, oil can thicken to the point where the oil pump can no longer force the oil through the lubrication system or the oil can solidify into a solid mass that resembles wheel bearing grease. In the second case, the oil pump may be able to pump the oil around the engine, but the engine can still suffer accelerated rates of mechanical wear because certain critical additives may have been depleted or destroyed to the point where they no longer exist, even though the oil’s viscosity may still be within an acceptable range of values.

In practical terms, additive packages are expressly designed to prevent both of the above conditions, but since additives are also sacrificial, additive packages are designed so that the most critical individual additives all resist depletion and/or mechanical destruction (almost) equally well. Of course, this assumes that the oil formulation in question conforms to the standards set out by both internationally recognised regulatory bodies and car manufacturers.

To accomplish both requirements, the development of additive packages that suit operational demands and are compatible with variable mineral base oils has evolved into an extremely exact science. We need not delve into the fine details of that science here beyond saying all modern additive packages are the result of a difficult-to-achieve marriage between three broad categories of additives, with each category of additives containing substances that have specific tasks or roles within the overall oil formulation. Consider the table below-

|

Enhancement of Existing Base Oil Proprieties |

Suppression of Undesirable Base Oil Properties |

Conferring New Properties to Base Oils |

|

Antioxidants |

Pour-point depressants |

Extreme pressure additives |

|

Corrosion inhibitors |

Viscosity improvers |

Detergents |

|

Anti-foaming agents |

|

Metal deactivators |

|

Demulsifying agents |

|

Tackiness agents |

It should be noted that the above table only lists the principal organic and inorganic ingredients in each category of additives that each forms a critical part of a modern oil formulation. In practice, both organic and inorganic additives can be either dissolved into the base oil or remain suspended in the base oil in which case the base oil transports the additive particles around the engine as it (the base oil) moves through the oil circulation pattern, which begs the question of-

We have all seen accumulations of sludge (like the example shown here) in engines before, but the point of this image is that the formation of sludge happens for only two reasons. The first is irregular servicing that leads to severe depletion of some additives, and the second reason is the mixing of different oil brands and formulations that leads to some critical additives being deactivated by undesirable chemical actions/reactions between incompatible substances in the different oil formulations.

The first point is self-explanatory, but before we get to the specifics of how oil additives work, we need to explain some aspects of the second point against the backdrop of the GF-6 oil standards. To qualify as a GF-6 compliant formulation, that formulation must satisfy, among many others, at least the following requirements-

Developing such formulations are of course, extremely expensive so all participating oil formulators not only do their level best to win the required approvals, but they also go to great lengths and huge expense to protect their intellectual property (i.e., oil formulation “recipes” and internal test reports/procedures/protocols) by registering and securing patents and other protections in as many international jurisdictions as possible.

So, although oil brands “X”, “Y”, and “Z”, may all win approval by say, Ford, to market their products as suitable for use in new Ford products, the additive packages in all three oil brands will be different in terms of the actual additive substances used, as well as in terms of the relative concentrations of each substance with regard to both the base oil and all other additive substances.

Situations like the above are possible because a) oil formulators are not obliged to use the same additive substances as everybody else and b) many, if not most additives that do the same thing(s) exist in multiple different forms, which offers oil formulators a handy workaround to avoid potential patent infringement disputes and hugely expensive lawsuits. The guiding principle here seems to be that since all roads eventually lead to Rome*, anybody is free to take any road to Rome, as long as nobody trespasses on anybody else’s road on the way there.

* Speaking metaphorically, “the road to Rome” translates into the complicated processes of meeting regulatory requirements and winning car manufacturers' approvals.

So, there we have it; the underlying reason why mixing different oil brands and formulations is a bad idea; you just never know what additives are in any given oil formulation that might clash or inactivate some additives in one or both oil formulations you are mixing. Worse, though, by mixing oil formulations one might just initiate a series of chemical reactions between incompatible additives that could potentially (but often does) turn the mixture into a near-solid lump of greasy jelly, with invariably disastrous results for engines in which this happens, which brings us back to the question of-

Although the efficacy of most oil additives generally does not depend on the oil’s overall viscosity when the oil is still within its “useful life span”, there are some notable exceptions to this rule. However, the relationship between the overall chemical composition of oil additive packages and the effects of an additive package on the viscosity of base oils at different temperatures is extremely complex and technical, and as such, this aspect of oil additives falls outside the scope of this article.

Before we get to specifics of how additives work, it is worth mentioning that some additives work exclusively within the volume of oil in the engine, while others work exclusively on metal surfaces. Moreover, additives that work within the volume of oil are mostly polar in nature, since these additives need to bond with contaminants to be effective at trapping or neutralizing things like water molecules and diesel soot particles. With that said, let us look at some polar mechanisms-

Particle enveloping

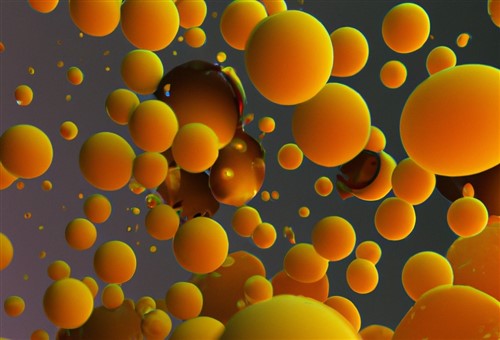

This AI-generated image illustrates the principle of particle enveloping. In this example, the yellow additive particles first encircle, and then attach themselves to several carbon soot particles (rendered in brown here) to keep the carbon particles in suspension in the oil to prevent the particles from settling out of the oil to form sludge on an engine’s internal surfaces.

In practice, enveloping additives include metal deactivators, detergents, and dispersants that disperse particularly diesel soot particles and other combustion waste products to prevent these contaminants from clumping together at low or moderate temperatures. However, the collective volume of metal deactivators, detergents, and dispersants in engine oil is finite, and once all of these additive particles have bonded with contaminants, these additives are depleted and the process of preventing contaminants from settling out of the oil to form sludge stops.

Water emulsifying

Emulsifying additives work by attaching themselves to water molecules within the volume of oil to prevent the water from settling out of the oil. In essence, this means that while the emulsifying agents keep water molecules entrained within the oil, high levels of moisture in the oil cause the rapid depletion of emulsifying additives, which in turn, negatively affects the operation of other additives such as, among others, corrosion inhibitors and metal wetting agents.

The rapid and/or complete depletion of emulsifying additives is the main reason why we sometimes see corrosion on the inside surfaces of steel tappet/valve covers and valve train components even on engines that receive regular oil changes. In such cases, the oil contains too much water for the emulsifying additives to capture all the water molecules, so water vapour separates from the oil and condenses as droplets onto metal surfaces when the engine cools down, thus creating the rust or corrosion we sometimes see.

It is perhaps worth remembering that the main source of moisture in engine oil is atmospheric water vapour that enters the engine via the PCV (Positive Crankcase Ventilation) system. If this system is defective in some way and does not remove waste gasses and water vapour from the crankcase, the concentration of water molecules in the oil can reach the point where the sheer volume of water in the oil overwhelms the ability of emulsifying additives to keep the moisture entrained in the oil. Ergo, the engine begins to rust on its internal surfaces, which brings us to-

Limited space precludes a comprehensive discussion of all possible additives commonly found in modern oil formulations, but we can do the next best thing, which is to discuss some of the principal additives that are common to all modern oil formulations. Let us start with-

Metal wetting additives

Metal wetting occurs when some types of additives attach themselves to metal surfaces at the molecular level to form thin but extremely durable lubricating films between sliding and rotating surfaces. Such additives include friction modifiers aka anti-wear additives, additives that resist extreme mechanical pressures and shear forces, as well as corrosion inhibitors and tackiness agents that assist in creating strong chemical bonds between additives and metal surfaces.

The most commonly used friction modifier is zinc dialkyl dithiophosphate (ZDDP) because it is highly effective in preventing metal-to-metal contact during boundary lubrication conditions.

Anti-oxidizing additives

Contact with oxygen is arguably the single biggest factor that reduces both the useful life and lubricity of all modern engine oil formulations. As a practical matter, oxygen attacks the weakest components of an oil formulation, and it happens at all temperatures, and all of the time that the oil is exposed to atmospheric oxygen.

The effects of oxidation include the formation of various acids that among other things cause a measurable increase in the oil's viscosity and a general reduction in the oil's useful life.

Corrosion inhibitors

These additives work by neutralising acids and repelling moisture from metal surfaces by forming a protective film on metal surfaces that is impermeable to water molecules. It is worth bearing in mind though, that corrosion inhibitors are for the most part, specific to different metals, meaning that any given oil formulation could contain multiple different types of corrosion inhibitors.

Viscosity (index) improvers

These additives are very large polymer molecules that expand at high temperatures to prevent the base oil from “thinning out” too much at high temperatures. At the same time, these additives assist in preventing the base oil from coagulating at low temperatures, thus improving the engine’s ability to pump the oil around the engine at low temperatures.

However, because these polymer molecules exist as long molecular chains, they are susceptible to being easily “chopped up” by mechanical shearing forces. As the molecular chains are “chopped” up into progressively smaller pieces by shear forces, their ability to prevent the oil from thinning out at high temperatures decreases in an almost linear relationship to their decreasing length(s). When the pieces of molecular chains reach a minimum allowable threshold, they become unable to modify the oil’s viscosity at all, at which point the oil formulation’s useful life ends.

Detergents

Modern detergent additives are typically derived from calcium or magnesium, and as their name suggests, detergents keep metal surfaces free from sludge or other deposits. Detergents also neutralise acids in the oil, and as such, they form the basis of the alkalinity of the oil, which is expressed as an oil formulation’s base number.

It is worth noting though, that detergents are always used in conjunction with dispersants that hold the contaminants that detergents remove from metal surfaces in suspension in the base oil.

Pour-point depressants

An oil formulation’s pour point can be defined as (about) the lowest temperature at which that formulation will remain a liquid. This metric is particularly important in base oils that contain high concentrations of paraffinic wax that form large crystals at low temperatures. When the wax crystals begin to clump together at low temperatures, they form a strong lattice-like network or structure within the oil that prevents the rest of the liquid components of the oil from flowing, which leaves us with this-

Although this article did not touch upon the differences between mineral and synthetic oils, it is worth bearing in mind that neither synthetic nor mineral base oils have a significant inherent lubricity. In fact, the only function that base oils have is to transport the additives that actually lubricate and protect an engine against mechanical wear around the engine.

While this is true for all modern oil formulations, it also helps to remember that car manufacturers recommend a specific oil formulation for use in their products for very good reasons. These include the fact that additive packages are now being developed to meet all the lubrication requirements of specific engines, as opposed to meeting some of the lubrication requirements of some engines some of the time- as was the case until comparatively recently.

As a point of interest, it is worth mentioning that engine lubricants that do not contain oil are now being developed for the automotive market. However, until these lubricants become available, the best thing we can do for our customers is to only use the oil the manufacturers of their vehicles recommend or specify when we service their vehicles because doing so means we do not have to worry about whether (or not) the oil we are putting into their engines contains enough of this, that, or the other additive(s).