This writer was recently invited to consult on a case that involved a BMW with VANOS issues, but this article is not about variable valve timing issues on BMW engines. This article is about tyres, because while working on the vehicle, this writer noticed a bulge on the tyre on a front wheel, just like the one shown in the above image. When this writer pointed this out to the vehicle's owner, the owner just shrugged his shoulders and said that the bulge had been there for a while and that he'll get around to having it "fixed" when he has the time, which reminded this writer of a cautionary tale he’d read a while ago.

The events in this tale actually happened, and it involved an insurance claim that was denied when a vehicle was lost in an accident because it was deemed unroadworthy, and therein lies a lesson for all of us who perform safety inspections on our customer’s vehicles. Here are some details of the-

Limited space precludes a comprehensive discussion of this case, but you can find the relevant details in this determination by the Australian Financial Complains Authority. However, we can do the next best thing, which is to quote some of the most pertinent details of the case directly from the determination, which was published on 12 June 2020-

1) The complainant was driving in heavy rain, lost control of the vehicle, and hit a fence.

2) The financial firm (insurer) denied the claim. It says the insured vehicle was not in a roadworthy condition at the time of the loss and this was directly responsible for the incident.

3) The complainant considers the outcome unfair and says the loss occurred due to the weather conditions. He says he should be covered under the policy.

NOTE: The insurance company appointed a forensic investigator to inspect the vehicle after the accident, and based on the forensic evidence, the Australian Financial Complains Authority made the following-

Key findings

1) The forensic investigator found that "...[because] of the well-worn condition of the rear tyres fitted to the vehicle and the driver’s statement that he lost control over the steering of the vehicle when travelling during a period of torrential rain, the poor condition of the rear tyres would have been a major contributing factor to the driver’s loss of control over the vehicle.” (Italics added for emphasis)

2) This is based on (the forensic investigator’s) views that the rear tyres did not meet the relevant required state driving standards. These standards require [a] tread depth of a minimum 1.5mm. This was not the case in five of the 10 tyre checkpoints reviewed by [the forensic investigator.]

3) The insurer is [therefore] entitled to rely upon the exclusion for the vehicle not being roadworthy to deny the claim. This is because the exchanged evidence shows the condition of the vehicle's rear tyres caused or at least was involved with, the complainant's loss.

4) The insurer’s policy broadly provides cover for accidental loss or damage. This cover is subject to the terms and conditions (including exclusions) outlined in the policy documents. [Therefore]”...the insurer does not cover losses that are caused by or involve [an unroadworthy condition]. (Italics added)

5) There does not have to be a direct causal link for the exclusion to apply. There at least has to be evidence to show the unroadworthy nature of the vehicle was involved with the loss. (Italics added for emphasis)

So what does any of the above have to do with us as technicians, especially given the fact that most car owners consider replacing tyres a grudge purchase, and put it off for as long as they possibly can? You may well ask because while this particular dispute with an insurance company did not involve mechanics and workshops in any way, it could very well happen that an improperly performed tyre repair or tyre fitment might involve you and/or your employer in a similar dispute.

While we as technicians and mechanics cannot be blamed if our customers are involved in accidents and/or disputes when they ignore our advice to replace worn or damaged tyres on their vehicles, we nevertheless have a clear responsibility to point out defects in tyres when we perform safety inspections, and/or repair serviceable tyres, and for reasons that involve-

According to an official Government source, there were just over 14.2 million passenger vehicles registered in the country in 2018, and each registered passenger vehicle travelled a total average distance of between 12 000km, and 13 000km that year. While this may be mildly interesting to some readers, what should be hugely interesting to all readers is that according to another report, which was published by Budget Direct earlier this year-

More alarmingly though, the report lists the most common causes of vehicle accidents (that occurred in 2019) in this order of prevalence-

While there are no reliable statistics available for how many fatal crashes are directly attributable to the condition of the tyres on speeding vehicles, it would be reasonable to assume that tyre condition plays a role in at least a significant percentage of fatal crashes. More to the point though, although there are no reliable statistics available on tyre condition as a cause of fatal accidents, the fact is that when a vehicle travels at high speeds, the condition of its tyres is often the only thing that keeps it on the road, as opposed to ending up in a ditch or at the bottom of a cliff, which brings us to-

We stated elsewhere that most car owners see tyre replacements as grudge purchases. Despite this though, and while we cannot force a customer to replace worn or visibly damaged tyres, we can do the two next best things, which is to educate customers on the need to maintain their tyres, and to ensure then when we repair tyres we do it right, so let us look at-

The image above shows an example of a perfectly usable tyre that can be repaired safely: a simple puncture that can be repaired by removing the screw and inserting a plug, but note the two arrows that indicate the area across the tyre tread in which plugs can be inserted safely.

On most modern radial tyres, the tread width outside of this area is where the tyre deforms the most under cornering forces, which means that the bonds between the various foundational layers and the steel reinforcing layers in these areas are stressed the most. In fact, the shoulder of a modern radial tyre is where the tread and reinforcing layers transition into the sidewall, and as a result, the tyre is weakest at this point.

Thus, given the fact that the steel reinforcing layers do not extend into the sidewall proper, any damage caused to a tyre’s shoulder area, first by a foreign object, and then by the insertion of a flexible plug* could (and often does) cause the various layers of the tyre at this point to separate during normal vehicle use. The most common sign of such a separation is a bulge on a tyre’s sidewall, which is evidence that air is intruding into the structure of the tire at the site of the bulge.

* All tyre manufacturers recommend that perforations in tyres that are bigger than 6mm in diameter not be repaired with plugs (or in any other way), including fixing adhesive patches over the hole on the inside of the tyre, since such large holes can cause the weave pattern of the steel reinforcing bands to disintegrate around the site of the puncture. Moreover, air can enter the structure of the tyre around large holes, causing the tread and reinforcing layers to separate around the circumference of the tyre.

NOTE: Tyre manufacturers also recommend that multiple plugs in a tyre should not be closer than 350mm from each other as measured around the tyre’s circumference, even if the holes are smaller than 6mm in diameter. This precaution is designed to prevent the weave pattern of the steel reinforcing bands from unravelling between repair sites as the tyre deforms during normal use.

Other causes of bulges on the sidewalls of tyres include impacts between the tyre and rocks and/or other road debris, and of course, tyres making contact with curb stones during parking. Such a tyre is NOT repairable because the structural layers of the tyre have separated, and therefore, the tyre must be discarded to prevent it causing a potentially fatal crash when it fails catastrophically.

Of course, on a purely practical level, customers tend to not like it when we replace tyres on their vehicles without their consent, so when you do encounter a vehicle with bulging tyres, we suggest that you-

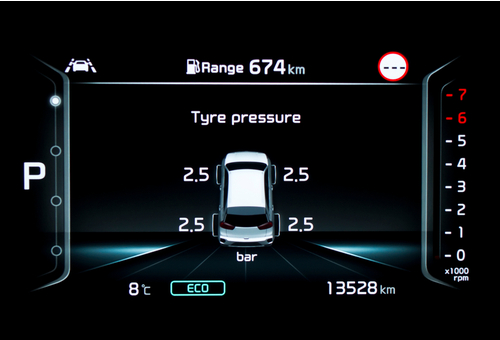

From a safety perspective, there is no justification for caving in to a customer’s demand that an un-repairable tyre be repaired to save that customer a few dollars. Similarly, there is no justification for failing to run a diagnostic scan on a vehicle’s tyre pressure monitoring system when we perform a safety inspection on a customer’s vehicle, both to obtain tyre pressures as measured by the system and to ensure that all tyre pressure sensors are functional. Having said that, let us look at-

We all know and appreciate the fact that it is the combination of the rubber compound, and the design/construction of a tyre that defines the amount of traction a tyre has. However, we often forget that apart from providing traction, a tyre also has to absorb acceleration, deceleration, and severe cornering forces without deforming beyond a specified limit, while lasting for a reasonable amount of time, at the same time.

To do all of this, modern tyres have become marvels of chemical and mechanical engineering, but to perform as designed throughout its useful life, a tyre has to be inflated to a very narrow range of pressures to eliminate a wide variety of vehicle handling and performance issues. We all know this to be true, but despite this, we often blame poor steering and/or braking responses, uneven tyre wear, weird vibrations and even excessive road noise on worn shock absorbers, worn suspension and/or steering components, or even on our customers' poor judgement in choosing tyres.

Here is another question; when you perform a safety inspection do you rely on information from a vehicle's tyre pressure monitoring system, instead of taking physical readings of the inflation pressure of each tyre with a reliable digital tyre pressure gauge? Do you merely accept that the tyres are inflated correctly because the tyre pressure monitoring system tells you they are inflated correctly?

If you are new to the car repair trade, you should know that a vast body of technical literature exists that describes the notoriously inaccurate nature of modern tyre pressure monitoring systems. In particular, though, many researchers have found that almost all tyre pressure monitoring systems in use today are calibrated to only report tyres as underinflated when their inflation pressure reaches a point that is about 25% under the recommended pressure.

Even the most accurate systems will only report tyres as underinflated when their inflation pressures fall about 10% to 15% below their recommended inflation pressure. Worse, though, the most accurate systems are typically fitted to high-end, high-performance vehicles that need their tyres to be inflated correctly more than a sedate passenger vehicle.

Thus, the majority of vehicles of all classes on Australia's roads are running with chronically under-inflated tyres, which greatly reduces a driver's ability to maintain control over his vehicle at high speeds, simply because under-inflated tyres cannot perform as well as tyres that are inflated correctly.

For instance, instead of transferring braking, steering, and acceleration forces to the road surface, an under-inflated tyre deforms excessively under these forces. Thus, instead of transferring a steering input to the vehicle, excessive tyre deformation absorbs much, if not all of the steering input, which typically results in an exaggerated understeer situation that could result in a driver losing directional control of the vehicle.

The same is true of braking forces; instead of a tyre converting its traction coefficient into a braking force, an under-inflated tyre merely deforms, thus absorbing much of the the braking force into its structure, instead of transferring the braking force to the vehicle to slow it down. If we add to the above two scenarios the fact that as much as 60% of the tread width of a tyre that is 25% under-inflated is not in full contact with the road surface, it becomes clear that a direct correlation exists between the degree of under-inflation and the possibility of a driver losing control over his vehicle. Of course, this begs the question of-

Sadly, there is no simple answer to this question, simply because there too many variables involved. For instance, things like a tyre's diameter, width, traction rating, speed rating, as well as other factors that include load ratings, ambient temperatures, road surfaces, environmental factors; the type of vehicle and how that vehicle is used all play roles in the inflation pressure that works best for that particular vehicle/tyre combination.

Therefore, given this wide range of variables, it simply makes no sense to rely on a vehicle’s tyre pressure monitoring system to maintain proper tyre inflation. This writer has seen many instances where a tyre pressure monitoring system reported all tyres on a vehicle to be inflated correctly when there were differences in actual inflation pressures of as much as 40% (and sometimes more) between individual wheels. To appreciate the implications of this reality, consider the image below-

Image source: http://www.hometyre.co.uk/assets/resized/_400x300_Tyre_damage_inside.jpg

The powdery substance circled in yellow in this image is a pile of rubber that had flaked off the inside of the sidewalls of a tyre that had been chronically under-inflated, despite the tyre pressure monitoring system on the vehicle not reporting the tyre as under-inflated. This type of damage occurs when the deformation of the sidewall causes localised overheating of the sidewall, and although this is an extreme case, this kind of damage is not visible from the outside of the tyre.

The first sign that something was amiss with this tyre was when it would not remain inflated for more than a few days. Since no leaks were apparent when we placed it in a tank of water, we concluded that there must be a slow leak in the area where the bead seats on the rim. Therefore, we removed the tyre from the rim to clean the bead area, which was when we discovered the pile of flaked-off rubber. This writer had seen similar problems with chronically under-inflated tyres before, but in this case, large sections of the inner sidewalls had disintegrated; in fact, this particular tyre was a blowout looking for a place to happen.

The weakest points of any tyre are the sidewalls because unlike the tread and shoulder areas that are reinforced to remain stable when the tyre is loaded, the sidewalls are required to flex and deform, and as a result, the sidewalls are not reinforced. In practice, the only thing that allows the sidewalls to support both the weight of the vehicle and the loads that normal driving place on a tyre is the tyre's inflation pressure.

So, back to our original question: what is the correct inflation pressure for any given tyre? Many car owners, and even tyre fitment centres, tend to regard the pressure values indicated on a sticker inside the vehicle. However, these pressures are typically the maximum allowable inflation pressures, which do not allow for a), expansion of the air in the tyre when it heats up during normal use, and/or b), for the compression of the tyre that happens when the vehicle is loaded. Thus, when a tyre is hot after use, and especially when the vehicle is loaded, the tyres’ inflation pressure should not exceed the values printed on the sticker in the vehicle.

In practice, the best thing to do is to use the recommended inflation pressure as indicated on the sticker in the vehicle (or in the user manual), which is always lower than the maximum pressure. This might seem like a self-evident truth, but the fact is that many car owners confuse “maximum” pressure with “recommended” pressure. This is a dangerous practice because a tyre's inflation pressure can rise by as much as 0.5 Bar when it gets hot during use, and particularly if the vehicle is carrying a full load of passengers, which leaves us with this-

In the real world, over-inflated tyres can be just as dangerous as under-inflated tyres, but sadly, we, as mechanics, cannot control how our customers maintain and care for the tyres on their cars. Therefore, the best thing we can do for our customers is to educate them on the need to have both the condition, and the inflation pressures of their tyres checked at least once a month, or more often if possible. We can also educate our customers on the inherent inaccuracy and unreliability of tyre pressure monitoring systems in general and against the dangers of developing an over-reliance on these systems, in particular.

One particularly effective method of educating customers on the importance of proper tyre care and maintenance is to take individual tyre pressure readings with a digital pressure gauge while the customer is present to see the results since readings that differ by as much as 30% between wheels are common on today’s vehicles.

While some customers see this as a scare tactic, they often begin to see things your way when you explain that the condition and inflation pressure of their tyres represents the difference between them arriving safely at their next destination, or having a potentially fatal accident on their way to their next destination because one or more tyres failed catastrophically as a direct result of not having been inflated correctly.