The vehicle in this case study was sold by a used car dealer. Some time after, it came in with the check engine light illuminated and a loud rattle from underneath the vehicle when the engine was running.

A P0420 Catalyst System Efficiency Below Threshold (Bank 1) fault code was retreived from the engine management computer.

Upon visual inspection, it was found that the whole upstream catalyst was missing, with the exception of the outer metal sleeve which was causing the rattling noise. The downstream catalyst also showed signs of substrate damage.

The used car department elected to fit used upstream and downstream catalysts for bank one which resolved the P0420 Fault Code but not the underlying concern that caused the catalyst substrate to break down.

RHS (bank 1) upstream catalyst

LHS (Bank 2) upstream catalyst

The vehicle had also happened to have a rough idle, upon re-checking codes a P0305 Cylinder 5 Five Misfire Detected fault code was present.

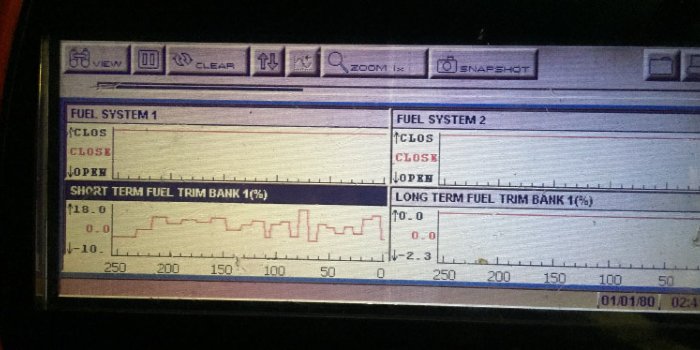

The live data on the scan tool indicated that misfire counters were increasing on cylinder 5 and the fuel trims indicated an ignition/mechanical type of misfire.

Live Scan-tool Data

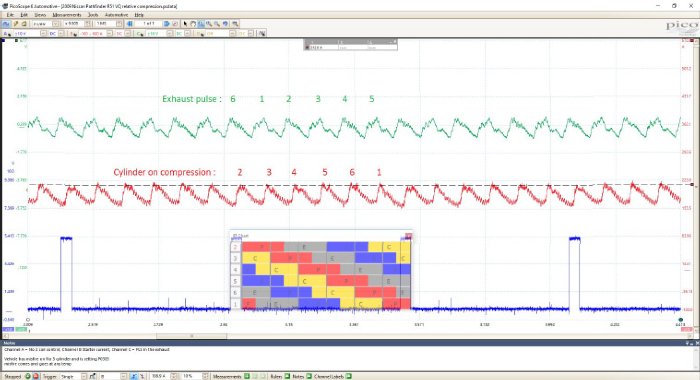

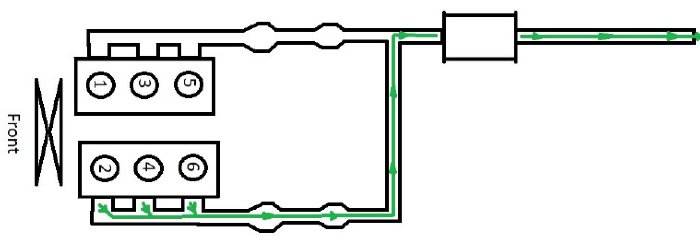

A relative compression test was carried out with a firstlook sensor in the exhaust to rule ont an engine mechanical concern.

Note: A relative compression test compares the difference between cylinders to identify an anomaly. In this application, the exhaust pulsations are measured while cranking. A relative compression test can also be carried out by measuring starter motor current draw as a waveform.

All looked ok and even between cylinders

Because we are dealing with a cranking waveform with no combustion taking place in the cylinders

there is a negative pressure in the cylinder when the exhaust valve opens.

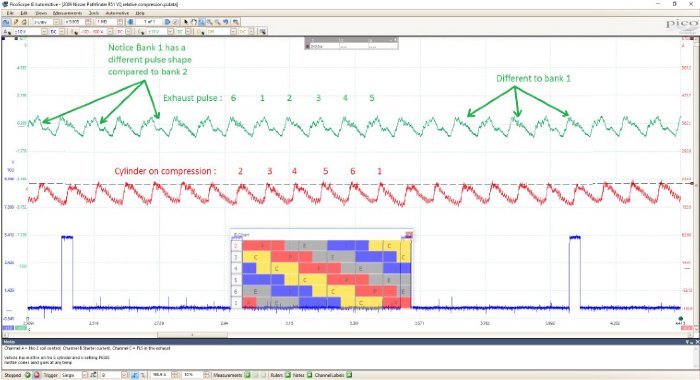

If you have a close look you can see bank 1 and bank 2 exhaust pulses look different to each other as shown below.

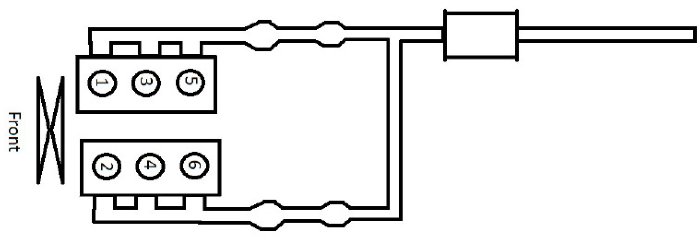

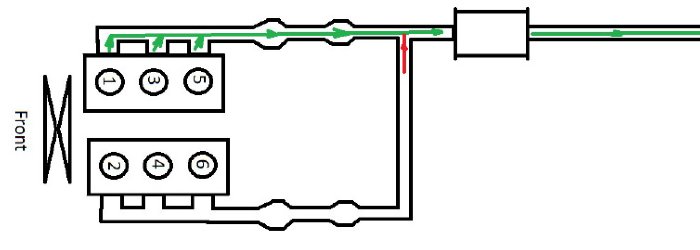

The simple explanation for the difference in pulses is how the exhaust system is shaped.

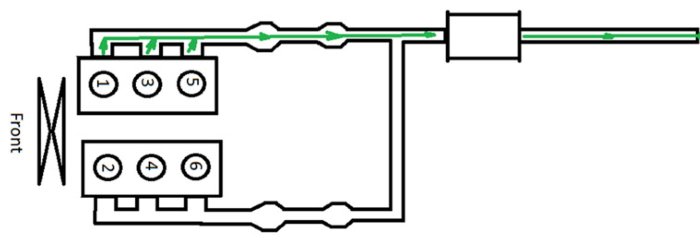

Here is an example with any of the 3 cylinders firing on bank 1

It is clear that bank 1 has a relatively short path and minimal bends as opposed to bank 2 as shown below.

Now you may ask why the bank 1 pulse dips a little whereas bank 2 doesn’t.

Regardless of whether it is a negative or positive pulse with any of the bank 1 cylinders, the exhaust pipe is

acting like a venturi and causing a pressure differential and drawing more volume as it flows past the

crossover pipe.

Now that we have established that there isn’t a mechanical issue with the engine, we can move onto chasing an ignition misfire on number 5 cylinder.

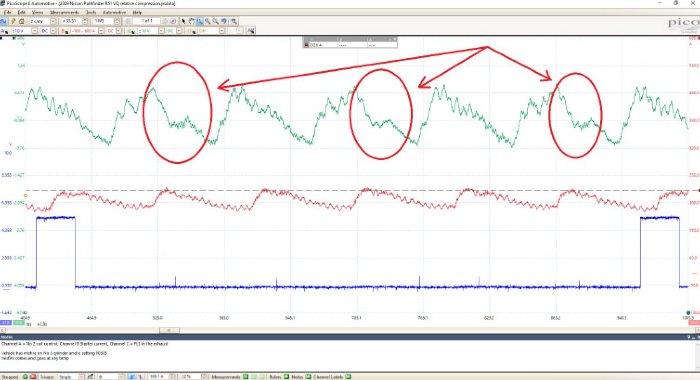

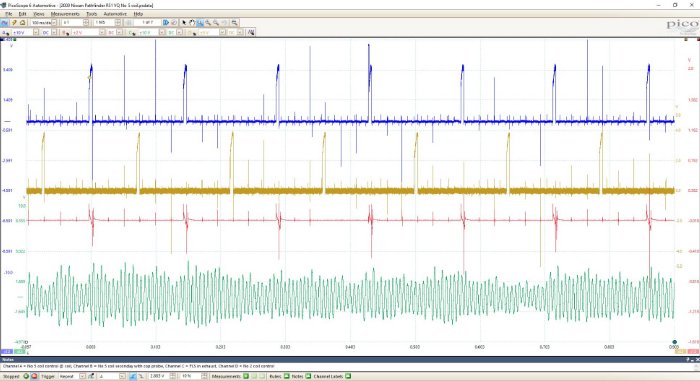

You can see the firstlook sensor is very difficult to interrupt in this picture once the engine is running

due to resonance (putting some rags in the exhaust pipe can help with some back pressure to

smooth it out a little bit)

The other thing to note here is a spike 4th No 5 coil command and also worth noting the spark line looks

low. (see zoomed in coil command event below)

Now is time to touch base and cover some background on most Nissan coils characteristics before we figure out what is going on here.

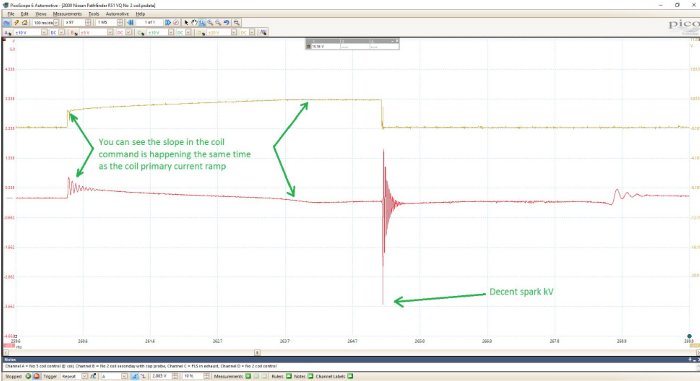

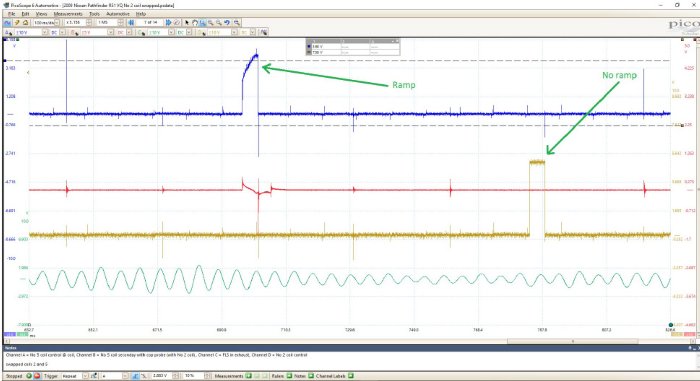

When sent a 5V signal from the ecu to fire the coil, it is normal to see a slope that corresponds with the current ramp of the ignition coil primary windings.

Below is a trace of a good known coil.

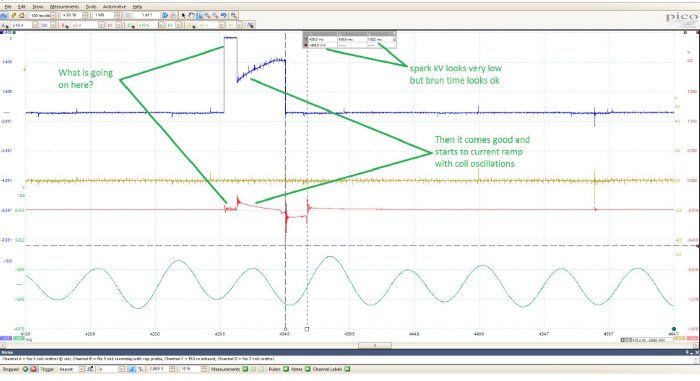

So know we have established the slope/ramp in the coil command is normal what would cause it to 5V then start to ramp?

This was the next screen on the scope:

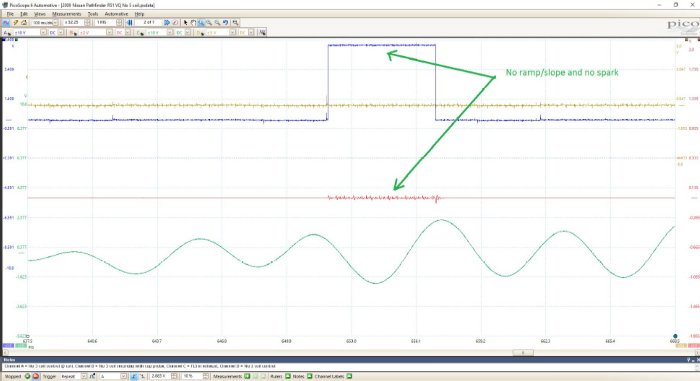

Cylinder #5 spark line disappeared and only a little bit of noise was present. See zoomed in trace below.

So now we can see no ramp in the command and no coil output. This was then swapped with cylinder #2 coil and retested.

Note: When swapping ignition coils in an attempt to determine a fault, an issue with terminal fretting, tension or intermittent wiring connections may cause the issue to accidently resolve and may lead to a misdiagnosis.

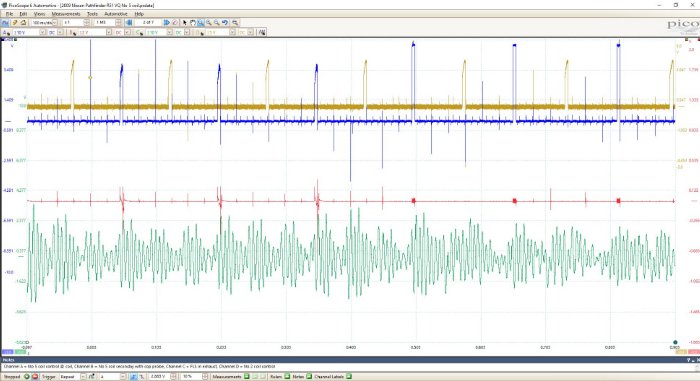

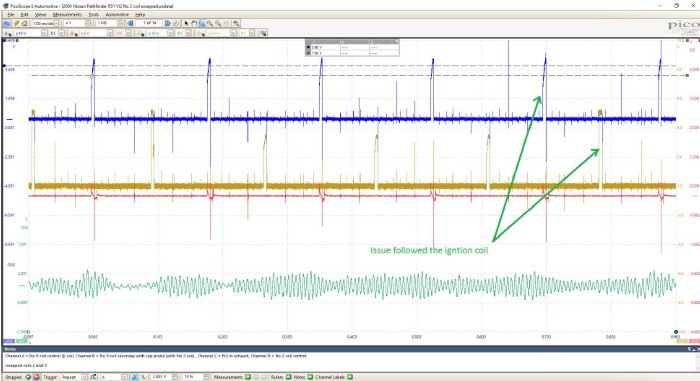

In the trace below, we can see that the sympoms on our scope trace have 'followed' the ignition coil.

So we have identified that the issue is with the coil, but what is the actual problem?

It would appear that the ignition coil primary windings are failing once the coil gets warm and spark comes and

goes because of it.

After checking spark with a normal spark tester, the ignition coil intermittently jumps a 10kV gap, which confirms the weak output.

After replacement of the spark plugs and ignition coil (at customers request) the vehicle was running smoothly again.

Don't forget, it is always important to investigate not only the Symptom, but the Cause of a fault to prevent further unnecessary damages and repairs!

Thanks to Anthony Lamb for sending in the case study for this article.

Do you have an interesting case study or technical article? Submit it here