As technicians, we play a critically important role in the battle against climate change, although climate change is sometimes the least of our worries when we are just trying to get through our collective day. Nonetheless, we, as technicians, represent a sort of interface between legislators that formulate ever more stringent emissions regulations, and the negative effects that the vehicles we work on have on both the local environment and the global climate.

Here are some examples of how this interface works; it is up to us to see that oil leaks are repaired to prevent oil from contaminating the soil and groundwater. It is up to us to see that EVAP (Evaporative Emissions) systems are repaired properly to prevent fuel vapours from escaping into the atmosphere. Most importantly though, is up to the A/C techs among us to ensure that harmful refrigerants are recovered from vehicles efficiently, stored safely, and then disposed of properly to prevent these gases from harming the atmosphere.

In terms of recovering and storing harmful substances, A/C refrigerants are perhaps the most insidious, since their negative effects on the atmosphere are both severe and long-lasting even though we do not see these effects immediately when an automotive A/C system is discharged into the atmosphere, as opposed to being captured by a legally approved recovery system. Thus, in this article, we will discuss currently used refrigerants and their effects on the environment, as well as take a look at what we can expect in terms of replacements for current refrigerants. Let us start by stating-

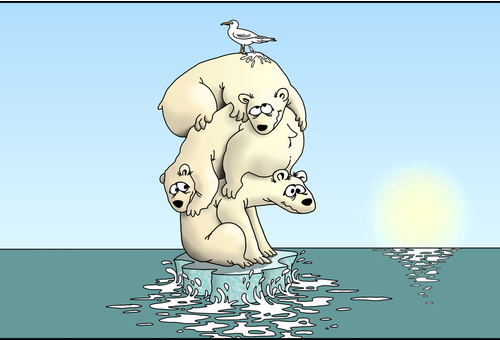

While R-134a on its own cannot be blamed for the predicament this group of polar bears finds itself in, there is no doubt that the unregulated and uncontrolled release of A/C refrigerants with a high potential to harm the atmosphere has made a significant contribution to global warming.

Before we get to the specifics of the problem with automotive A/C refrigerants, though, it is perhaps worth mentioning that the single most powerful driving force behind the strengthening of regulations to limit harm to the atmosphere is the EPA (Environmental Protection Agency), an agency of the United State’s Federal Government. While the EPA does not pretend to always speak the last word on emissions regulations since other countries have similar regulatory bodies, the financial power of the US automotive market is such that most US-grown emissions regulations are simply adopted by other markets, and mostly in their original form, at that.

The phasing out of R-12 as an A/C refrigerant is an excellent case in point. In the early 1990s, the US took part in a summit, known as the Montreal Protocols, during which it was determined that the chlorine in R-12 caused severe damage to the earth’s ozone layer when it was vented into the atmosphere. The upshot of this determination was that in 1994, the US forbade the import and sale of vehicles with R-12 in their A/C systems. The next step came in 1996 when the US mandated the use of R-134a as an A/C refrigerant because it did not contain chlorine.

As a result of this mandate, no CFC-based refrigerants had been produced in the US since 1996, and almost all manufacturers of CFCs outside of the US stopped producing this family of gases almost immediately after 1996 because vehicles using R-12 could not be exported to the US.

However, beginning in 2006, the EU started a campaign to first reduce, and then to eliminate the use of R-134a as a refrigerant, because although R-134a did not contain chlorine, it did contain various harmful forms of fluoride, which as it turned out, was extremely efficient at trapping greenhouse gases in the atmosphere.

It turned out that R-134a had a GWP factor of at least 1 430, meaning that if equal volumes of carbon dioxide and R-134a were released into the atmosphere, the R-134a would trap 1 430 times more heat in the atmosphere times than the carbon dioxide would. In scientific terms, “GWP” is shorthand for Global Warming Potential, and is expressed as a factor of carbon dioxide where carbon dioxide’s GWP is equal to 1.

This directive, known as Directive 2006/40/EC ran in several stages, and by 2017, the EU banned all A/C refrigerants with a GWP higher than 150, which effectively removed R-134a from the European automotive market. However, in 2015, the authorities (aka the EPA) in the US adopted a new policy known as SNAP (Significant New Alternatives Policy), Rule 20 of which stated that by 2021, no vehicle in the US would be allowed to use R134a or any other HFC (Hydrofluorocarbon based) refrigerants in its A/C system. This rule applied to both imported and locally-made vehicles, and although Rule 20 does make provision for some exclusions and exceptions, these are valid only until 2025.

So in practice, the problem with R-134a is that it is significantly more harmful to the atmosphere than R-12, the refrigerant it replaced, which begs the question of what will replace R-134a. It turns out that there is a suitable replacement for R-134a, known as r1234yf, but this gas is not without controversy and issues of its own, so let us look at-

During the switch from R-12 to R-134a, it was possible to convert systems running on R-12 to accept R-134a. While it was not a recommended procedure, many motorists and workshops did it anyway because of the high cost of replacing entire A/C systems, but perhaps mostly because A/C systems that were converted to run on R-134a still worked, albeit with severely shortened service lives.

However, things are a little different with the switch from R-134a to r1234yf. For one thing, there are no international mandates in place to reduce or limit either the production of or importation of R-134a into any automotive market. Although no new vehicles made after 2020 will be allowed to use R-134a, existing A/C systems that run on R-134a will be allowed to remain in operation until the vehicles that are equipped with R-134a A/C systems are taken out of circulation through a natural process of attrition.

Put differently, this means that since (on a global scale) at least 2 billion vehicles use R-134a as a refrigerant, the production and supply of R-134a will remain stable for at least another ten to twelve years, or at least until all the vehicles that use this refrigerant are scrapped. While this will allow R134a to die a natural death without disrupting current technologies, it is not clear how the several thousand tons of R134a and other fluorine-rich refrigerants that are now in use in automotive A/C systems will be prevented from escaping into the atmosphere over the next ten to twelve years.

The problem with R-134a is its very high GWP, so given the current global concerns over climate change, it seems strange that no automotive market seems to have pro-active measures in place to capture and sequester R-134a as vehicles are taken out of circulation, but that is perhaps a topic for another time.

For the moment though, the issues with R-134yf as a replacement for R-134a are many and varied, including the high cost of R-134yf, which is currently at least 12 to 15 times more expensive to produce than R-134a.

However, although R-134yf is a member of an altogether different chemical family from r-134a, being an HFO (Hydro Fluoro Olefin) based gas, the two refrigerants have similar chemical properties with regard to their pressure/temperature relationships and refrigeration cycles. So apart from R-1234yf systems requiring a somewhat larger expansion valve to compensate for the higher flow rates of R-134yf, but slightly lower specific heat of evaporation in these systems, most of the other components in R-134yf systems look similar to and work in the same way as those in R-134a systems.

Therefore, to prevent both motorists and workshops from filling R-134yf systems with R-134a to save some money, the EPA has published regulations and design details that require the two systems to have service ports that are a) incompatible, and b), to have service ports that cannot be made to be compatible. The theory behind these regulations is that since R-134yf has a GWP of only four, making it impossible to charge an r1234yf system with R-134a* would keep measurable amounts of harmful R-134a out of the atmosphere.

* The practice is somewhat different, however, since it is possible to find (illegal) adapters online that make it possible to charge R-134yf systems with R-134a.

Before we get to more specific problems with R-134yf, it is perhaps worth mentioning that recovering R-134yf is not greatly more time consuming than recovering R-134a, but the process also requires additional (and highly sophisticated) purity, leak detection, and cross-contamination prevention procedures that can only be performed with dedicated and legally approved equipment, which brings us to-

Although R-134yf is classified as only "mildly flammable", Daimler reported in 2012 that during crash tests that simulated head-on collisions, the A/C compressor on the test vehicle had fragmented and that the r1234yf refrigerant in the system had ignited when it came into contact with the hot engine.

Daimler also reported that the burning R-134yf gas had created a cloud of highly toxic hydrogen fluoride gas, which in their opinion represented an unacceptable safety risk, since vehicle occupants could conceivably choke to death before they could escape from a crashed and burning vehicle.

In response to these claims, the German Transit Authority, a German Government agency that has overall responsibility for establishing vehicle safety standards in Germany, as well as Honeywell and the Du Pont Company, who were both manufacturers of R-134yf, performed their own safety tests. However, as was reported at the time, the tests failed to replicate the results reported by Daimler. Put differently, these targeted tests could not get R-134yf refrigerant to ignite during any type of crash test.

Nevertheless, despite assurances by the German Transit Authority and the manufacturers of R-134yf that there is "little risk" of R-134yf igniting in crashes, Daimler and other German manufacturers, most notably Porsche, Volkswagen, BMW, and Audi, have adopted the use of R-744 as an A/C refrigerant in vehicles sold in Europe. However, these manufacturers continue to use R-134yf in vehicles they produce for the North American and other markets.

As a point of interest, Daimler vehicles that use R-134yf in markets outside of Europe come equipped with an argon based fire suppression system. In practice, this system is triggered by dedicated impact sensors, and if the system is not destroyed during an accident, cleverly arranged spray nozzles will deliver high levels of argon gas to areas in the engine compartment where the R-134yf refrigerant is the most likely to ignite, which brings us to-

R-744 is the trade name for carbon dioxide, which reached its peak as a refrigerant in the mid-1920s, with the reason for the decline in its use as a refrigerant being the advent of CFC-based gases that required much lower pressures to work. On the other hand, its resurgence of carbon dioxide as a refrigerant is due to the refusal of most major German car manufacturers to use R-134yf in Europe due to its flammability.

Nonetheless, although R-774 is more efficient as a refrigerant than both R-134a* and R-134yf, R744 comes with significant problems and issues. Let us look at two of these issues, starting with-

* Since the operating principles of R-744 as a refrigerant are too complex to discuss here, we will address this topic in a follow-up article.

Engineering difficulties

As a practical matter, many HVAC systems already use carbon dioxide as a refrigerant, but for the most part, these applications are large, stationary installations in industrial environments.

From an engineering perspective, the problem with carbon dioxide is that extremely high system pressures are required to make it work as a refrigerant. In fact, in automotive applications, an A/C system using R-744 needs to generate pressures that are at least ten times higher than those required for R-134yf systems and it is common to see system pressures as high as 100 bar (or even higher) in high ambient temperatures, as a result.

So from a design perspective, A/C systems that use R-744 as a refrigerant must withstand the effects of constant vibration and huge under-bonnet temperature swings. Additionally, all materials used in such systems must also be impervious to the effects of fuel and oil vapours. Moreover, flexible hoses (and their crimped fittings) must be able to contain the exceedingly small molecules in carbon dioxide- given that gases with larger molecules seep through the rubber compounds and crimped fittings of existing hoses.

Car manufacturers are acutely aware of these challenges, but instead of developing new materials, pipe connections, and pressure-resistant seals, German cars that use R-744 are equipped with dedicated sensors that detect the presence of elevated levels of carbon dioxide in the passenger compartment should a leak occur, which brings us to-

The toxicity of carbon dioxide

Although carbon dioxide occurs naturally in the atmosphere at a concentration of about 0.037 per cent (equal to about 400 parts per million) relative to the overall make-up of the atmosphere at sea level, the gas is not toxic at this concentration.

However, since carbon dioxide cannot be detected by humans even in very high concentrations, vehicle occupants can be overcome by the gas when it reaches highly toxic levels- without realizing that they are being poisoned.

In practice, when carbon dioxide levels approach or begin to exceed concentrations of around 800 parts per million, vehicle occupants can begin to experience symptoms that include (among others), dizziness, headaches, breathing difficulties, confusion, loss of concentration, reduced coordination of movement, and a gradual loss of consciousness that could, and sometimes does, result in death.

So, assuming that a carbon dioxide leak detection system works as designed, the system will shut down the A/C system and let in fresh air by opening closed windows and other dedicated vents when it detects carbon dioxide levels that approach 800 parts per million. In terms of practicalities, the problem with carbon dioxide is that it progressively displaces the air in the vehicle as its concentration rises and if a) enough carbon dioxide is available, and b) the leak in the A/C system is big enough, vehicle occupants can be overcome by the toxic gas in less than a minute should the leak detection system fail.

How this is not a bigger threat to vehicle occupants than the remote possibility of R-134yf igniting during an accident is not clear. But then again, it is not for this writer to question the motives of some car manufacturers when they choose to use a potentially toxic gas as an A/C refrigerant when safer, albeit more expensive alternative refrigerants are available.

Moreover, technicians are also at risk of asphyxiation by carbon dioxide. Simply working on a leaking carbon dioxide A/C system under an open bonnet or servicing a system that is pressurized to 100 bar or more presents unique challenges that require not only specialized training but also application-specific PPE to prevent injuries and health hazards, which brings us to a refrigerant known as-

R-152a is the trade name for difluoroethane, and like R-744, R-152a has been in use as a refrigerant in industrial HVAC systems for many years. R-152a is also commonly used as a propellant in aerosol cans, as a foaming agent in various industrial applications, and as a component in many refrigerant blends because it is fully miscible with a wide range of industrial and domestic refrigerants, including R-134a and R-134yf.

However, even though R-152a has a GWP (Global Warming Potential) of only 124 and an ODP (Ozone Depletion Potential) of zero, it has not seen a meaningful application as a refrigerant in automotive applications. The reasons for this lack of uptake are not entirely clear because while R-152a does have a measurable effect on the atmosphere, it is more effective as a refrigerant than all existing and previously used automotive refrigerants.

In addition, R-152a does not only work at system pressures that are more than 10 per cent lower than those required for R-134a, but it is also so closely (chemically) related to R-134a that R-152a can serve as a direct replacement for R-134a without the need to change anything in an R-134a system- including the lubricating oil. Moreover, the heat transfer coefficient of R-152a is not only at least 20 per cent higher than that of R-134a due to R-152a’s lower specific weight, but the lower viscosity of R-152a in its liquid phase also reduces the pressure drop on suction lines by about 30 per cent.

For those among us who are not A/C technicians, the above means that R-152 is not only a significantly more effective refrigerant than both R-134a and R-134yf, it also requires less energy to produce more cold air than either R-134a or R-134yf. However, despite its advantages, R-152a is mildly flammable, meaning that it could be ignited by an open flame.

For this reason, A/C systems in vehicles will have to include a thermal loop system that keeps the refrigerant out of the passenger compartment. In this case, the A/C system will cool a reservoir of inert liquid in the engine compartment, and this cold liquid will then serve as the source of the cold air that is pumped into the passenger compartment.

From a purely practical point of view, this loop system requires far fewer (and easier to solve) engineering challenges than R-744 does. Nonetheless, and somewhat strangely, instead of using a refrigerant like R-152a that is known to be safe, effective, and energy-efficient, many car manufacturers are currently researching ways and means of reintroducing extremely flammable and even highly toxic refrigerants, such as ammonia, back into automotive A/C applications, which leaves us with this-

Despite the engineering and safety challenges that come with R-744 as an A/C refrigerant, R-744 is more efficient than R-134yf, which translates into less fuel used to cool a vehicle's interior. Moreover, the limited heat-pump capacity of R-134yf makes it an unattractive choice as an A/C refrigerant in electric vehicles because an A/C system using R-134yf could reduce a high-voltage battery pack’s output by as much as 50 per cent.

Therefore, given the pressure on the automotive industry to promote the uptake of electric vehicles, it is likely that R-134yf is only a kind of stopgap replacement for R134a and that eventually, most car manufacturers will adopt the use of R-744 as their A/C refrigerant of choice, given the economies of scale that apply to the car manufacturing industry,

In practice, the cost of the engineering and safety challenges of carbon dioxide as an A/C refrigerant will likely be reduced to the point where it becomes economically viable to use carbon dioxide as a refrigerant even on entry-level vehicles within a few years, even though carbon dioxide is the primary driver of climate change.

Nonetheless, it remains a mystery, at least to this writer, why car manufacturers do not simply use existing, non-toxic, cheap, and effective albeit mildly flammable refrigerants in existing automotive A/C systems, with R-152a being an excellent example of such a gas. Perhaps we’ll never know.