Have you ever wondered why so many late-model cars are known as oil “guzzlers”? There are too many examples of known oil “guzzlers” to list here, but we are sure you have encountered many owners of relatively new vehicles who were told by dealerships that oil consumption rates of 750ml (and more) per 1000km are “normal”.

The prodigious amounts of oil some engines consume raises the question of what then constitutes an abnormal oil consumption rate, given that one would expect new engine designs and highly refined mass production processes to reduce oil consumption rates, instead of increasing oil consumption rates to ridiculously high levels. One also wonders how manufacturers of oil-guzzling engines manage to comply with stringent exhaust emission levels given the high rates of catalytic converter failures on engines that burn almost as much oil as they do fuel.

Sadly, we cannot answer all of these questions in this article, but we can do the next best thing, which is to take a closer look at piston rings, which represent the primary means of limiting oil consumption in all engines. Thus, in this article, which is the first in a series of articles aimed at explaining excessive oil consumption issues on new engines, we will discuss the role piston rings play (or often do not play) in controlling oil consumption rates in modern engines. Let us start with this question-

Few of us have the opportunity to inspect piston rings and to draw diagnostic conclusions from what we find in our daily lives. This is simply because, these days, few independent and we daresay, dealership workshops, tear down, recondition, and rebuild engines since this field of engine repair has largely devolved onto specialist workshops, which may or may not be a good thing- depending on your point of view.

Nonetheless, this writer knows several senior technicians who have never stripped down and/or assembled an engine, and as a result, these technicians often do not realise how far apart practice and theory can be when it comes to diagnosing some types of engine failures, such as or instance, excessive oil consumption on new engines.

The above statement is not intended to belittle anyone’s skills, knowledge, and diagnostic abilities, but the fact is that the functions of piston rings, in terms of what they are expected to do in many modern engines, often do not agree with what they deliver. Below, then, are the (expected) principal functions of piston rings in modern engines-

All of the above was relatively easy to accomplish with a high degree of efficiency on the engines of even just 20 years ago. However, the combination of steadily increasing compression ratios (with or without forced induction), steadily increasing combustion temperatures, and ever-more stringent exhaust emissions regulations has in many cases, turned the above list of functions into a kind of wish list, as opposed to a list of expected outcomes.

To be fair, though, not all manufacturers miss the mark in terms of piston ring efficiency to the same degree, largely because some manufacturers are sometimes more successful in imparting the following characteristics to their piston rings than others. Below are some details of the expected characteristics of an ideal piston ring-

The three points listed above describe an ideal piston ring, but since many piston rings do not possess all desired characteristics in equal measure, what do we just tell a customer who is complaining about his new car’s high oil consumption rate? Do we just tell the customer “it is what it is”, and there is nothing we can do about it, or do we attempt to explain the issue in some detail? To be sure, there is nothing we can do about many, if not most high oil consumption issues, but we can do the next best thing, which is to explain-

While it is not possible to make an engine that does not consume any oil at all during normal operation, the very high “normal” oil consumption rates we see on many new vehicles result from three things, these things being-

*We will discuss this point in more detail in a follow-up article.

Thus, in practice, the high rates of oil consumption we see on some engines are the result of tradeoffs between the designs of the actual piston rings in those engines, and deviations from an ideal design to achieve certain objectives that often do not include limiting oil consumption.

In some cases, a trade-off is made to achieve improved fuel economy through reduced friction, while in other cases, some manufacturers might choose to use uncoated piston rings to reduce manufacturing costs.

In all cases, though, a trade-off to improve a piston ring’s performance in one area always results in losing some performance in another area. However, since the effects of these kinds of tradeoffs differ between engines we cannot discuss all possible effects here, because there are simply too many variables involved.

However, what we can do is discuss how perfectly designed piston rings would perform in a perfectly designed engine, which if nothing else, should give you some insights into the secret lives of piston rings by illustrating the three principal functions of well-designed piston rings. Let us start with-

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

This image shows the first two rings in a typical ring pack, but note that the piston groove/ring clearances and other details such as the shape of the ring faces shown here are greatly exaggerated for clarity.

As mentioned elsewhere, the primary function of the top (compression) ring is to prevent combustion pressure from leaking into the crankcase. The problem is, however, that top rings do not have sufficient inherent spring tension to keep their faces pressed against the cylinder wall tightly enough to form a good gas seal during combustion.

Therefore, as shown here, the piston/ring combination is designed so that some combustion pressure can pass into the top ring groove to exert an outward force on the back of the ring to increase the pressure between the ring face and the cylinder wall.

Note though that in an engine that is in a good mechanical condition, i.e., the wear on all cylinder walls and piston rings is within allowable limits, this outward pressure peaks before the piston reaches its maximum speed halfway between TDC and BDC. As the piston slows down towards BDC, most of the pressure behind the ring dissipates, and it is completely dissipated when the piston starts its upward motion on the exhaust stroke.

In practice, the rise and drop of the pressure behind the top ring correlate almost perfectly with the increase in pressure during combustion, and the subsequent drop in pressure as the piston moves downwards towards BDC. Therefore, the contact pressure between the ring face and the cylinder wall is highest when the combustion pressure is highest, which helps to preserve combustion pressure in the cylinder as the piston begins to change the direction of its rocking motion between TDC and BDC.

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

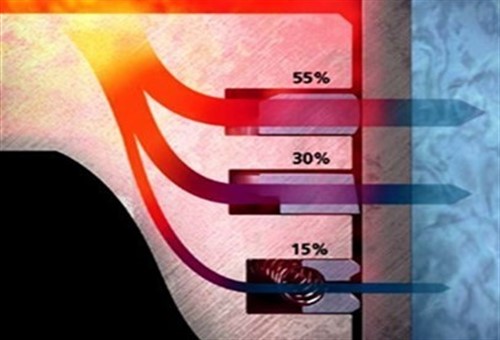

Since the part of a piston that accommodates the ring pack is not in contact with the cylinder wall, the high temperatures that piston crowns reach can only be dissipated through the piston rings, which are in contact with the cylinder walls. However, for piston rings to do this effectively, the ring faces must be in firm contact with the cylinder wall and the clearances between ring grooves and the rings must be within allowable limits to maximize the transfer of heat from the piston to the cylinder wall.

The above image shows how much of the thermal load each ring dissipates. Note that the values shown here are not absolute since ring wear, ring groove wear, ring design, the presence of carbon deposits in ring grooves, and the condition of the cylinder wall can influence the heat dissipation efficiency of each ring. Nonetheless, as a rule of thumb, piston rings in good condition dissipate between 70 per cent and 80 per cent of a piston's heat.

The remaining heat is carried away by expelled exhaust gas or managed by being-

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

Contrary to popular belief, oil control rings do not simply scrape excess oil off the cylinder walls. As shown here, oil collects between the raised contact surfaces of the ring and passes first through openings in the ring before passing through multiple openings in the piston to return to the crankcase. This is true for both solid oil control rings and oil control rings that consist of two separate rails and an expander.

There are two good reasons why oil control rings cannot simply scrape all excess oil from a cylinder wall, and both reasons involve the need to have a limited amount of oil present on the cylinder wall. The key here is “limited” amounts of oil, so let us look at this in some detail-

The primary function* of the second ring is to distribute and maintain a precisely defined film of oil on the cylinder wall that has to be-

* Second rings also have a limited function in preventing compression pressure blow-by.

Maintaining this oil film under all possible operating conditions is a very tall order indeed, and much of how well a second ring manages it depends entirely on how the second ring had been “run in”. Consider the image below-

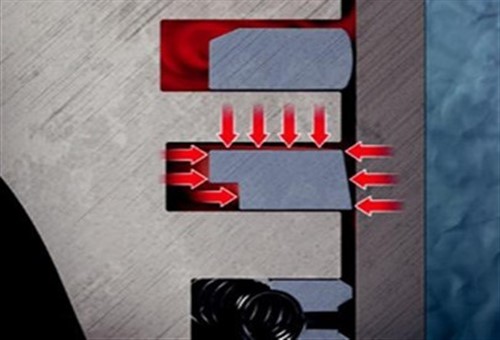

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

This image shows a second ring in its new, unused state, with the arrows indicating the direction of the various forces that act on the piston ring during normal engine operation. Note, though, that the angles and clearances shown here are greatly exaggerated for clarity.

Second rings are typically provided with a tapered face towards the cylinder wall, with the offset from the vertical usually ranging from 40 to 60 angular minutes- depending on the ring brand and version.

The tapered face has two functions; the first is to reduce the contact area between the ring and the cylinder wall to reduce the amount of material removed from the cylinder wall during the” running in” period. The second function is to provide a surface area for combustion gas pressure to counteract the ring's inherent spring tension to further reduce the amount of material the sharp edge of the ring removes from the cylinder wall.

As a practical matter, the need to remove sufficient material to polish the cylinder wall while preventing the excessive removal of material is an exceedingly fine balancing act. Therefore, to help balance the scales, in a manner of speaking, second rings are manufactured with a precisely calculated step in their rear surfaces that allows the ring to “twist”. Here is how it works-

As the piston moves upward towards TDC, hydrodynamic forces cause the ring face to lift off the cylinder wall to slide over the film of lubricating oil on the cylinder wall surface, which is the mechanism that distributes the oil film evenly over the surface of the cylinder wall. When the piston starts moving downwards, the ring twists in the opposite direction, causing the ring’s edge to “cut” into the oil film, thus scraping off excess oil towards the crankcase.

Over time, the sharp edge on the second ring wears down as a result of the ring twisting in both directions until, eventually, the tapered face wears down to the point where the ring assumes a largely rectangular cross-section.

At this point, the second ring’ face is perfectly matched (in theory, at least) to the surface of the cylinder wall, which means that the ring’s face is no longer lifted off the cylinder wall during the piston’s upward motion, and the engine will burn minimal amounts of oil, which leaves us with-

In many cases, the practice and theory of piston ring design and operation very frequently do not coincide, which results in even some new, or almost new engines burning copious amounts of oil.

Thus, in the next article in this series, we will discuss some specific aspects of piston ring design and operation that either directly cause, or contribute to the excessive oil consumption we see on many modern engines.