In Part 3 of this series, we made the point that cylinders on new engines are sometimes severely distorted as a result of how engines are designed and constructed. We also discussed the effects that such distortions have on oil consumption, and in this, the final article in this series, we discuss some specific piston ring performance issues that are directly traceable to deformed cylinders. Before we get to specifics though, we need to discuss two related, but pertinent issues, the first of which is-

Car manufacturers often make much of the fact that their engines do not need to be run-in, because their engines are, for all intents and purposes, user-ready. We can list all of their selling points here, but in the interests of brevity, we’d rather quote one major piston ring manufacturer on the topic of whether (or not) new engines should be run-in. Here is what this manufacturer of OEM piston rings has to say-

“Today, new engines are produced using state-of-the-art production methods. The interacting sliding parts are manufactured so precisely that the adaptation that previously took place during the running-in time of the engine has already taken place on the components in special manufacturing processes. This takes place in special manufacturing processes (e.g. for running surfaces of the cylinder liners), as well as through precision machining of the remaining interacting sliding parts.

This mainly involves lapping processes to free the surfaces from the ultra-fine burrs and surface unevenness(es) created during the machining processes. Previously, the adaptation process was carried out by the interacting sliding parts, which had to adapt to each other during the running-in time. This involved a significant loss of material. Pistons rings lost a significant portion of their wear reserves as early as the first hours of operation, for example. Particularly in today’s climate, where every milligram of emissions is fought over, engines are required to comply with their defined fuel consumption figures and the emissions limits from the very start.

An engine running-in phase, where the sliding surfaces have to adapt to each other first through friction and above-average wear, is therefore hardly conceivable at all in modern engine manufacture.” (Source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf)

If you work in an independent workshop and never see or work on brand new vehicles, the above statements might make sense, and you might even believe them. However, if you work in dealership workshops and see new engines burning enormous amounts of oil almost every day, the above statements look and sound more like an ideal that is yet to be achieved than statements of fact.

Let us think about this for a bit. If it were true that modern production methods were always so efficient that nobody needs to run in new engines anymore, why do we see so many new engines that often don’t make their first (1000 km) service without the need to top up the oil level? Moreover, in some cases, without the need to top up the oil level more than once?

We cannot answer that question here, but what we can say is this:

In the interest of fairness though, it must be stated that some engine manufacturing plants are better at finding and rejecting sub-par engines than others. However, not all engine plants can identify all such engines all of the time, meaning that while some manufacturers are known, if not notorious for building oil-guzzling engines, other manufacturers might see excessive oil consumption on only a few random engines from a particular production run.

Moreover, while some manufacturers are acutely aware of the fact that cylinder deformations on their engines result simply from the process of assembling these engines, they are also acutely aware that fixing the problem might involve an extensive engine redesign and development process, which is almost always prohibitively expensive in terms of both money and bad PR.

So what does this mean for us, as mechanics, that have to explain to some customers why their new-ish vehicles run out of oil every few hundred kilometres? This is a valid question, seeing that it has been this writer's experience that most car owners are generally not interested in modern engine mass-production methods, or more to the point, in the shortcomings of modern mass-production methods.

It simply means this; it is often easier, and more profitable in terms of time spent, just to explain to a customer-

While different car manufacturers use different methods to a) determine oil consumption rates, and b), to express oil consumption values/rates, one of the most common methods during an engine's development phase is to express oil consumption rates in grams [of oil] consumed per kilowatt-hour [of engine operation on a test rig]. Using this method, a well-designed piston/ring combination might produce an oil consumption value of 0.5 to 1 gram [of oil] per kWh. However, while this method can produce accurate (and repeatable) results under laboratory conditions, it does not work so well under real-world operating conditions.

Thus, for maintenance and servicing purposes, car manufacturers express the oil consumption rates for each of their engines either in litres [of oil] used per 1000 km travelled, or as a percentage of the total amount of fuel used over a given period.

The second method is the more accurate, because engines also consume oil while they are idling, or operating at very light loads during, for instance, slow traffic conditions. Moreover, since running accessories like air conditioning also place additional loads on an engine, expressing oil consumption as a percentage of fuel consumption provides a more complete "picture" of a given engines' oil consumption, because the calculation takes all the conditions the engine operated under during the test period into account

Thus, while every car owner has the legitimate expectation that his/her new car will not consume excessive amounts of oil, car manufacturers effectively counter this expectation by issuing expected (and therefore, acceptable to the manufacturer) oil consumption figures for each of the engines they make. In practice though, owners of new vehicles usually only become aware of acceptable/normal oil consumption rates for their engines when they complain about excessive oil consumption to the dealer.

Nonetheless, based on this writer’s historical maintenance records drawn from his workshop, it turns out that 20 years ago, most engines in new passenger vehicles consumed oil at a rate* of between about 0.25?per cent and 0.5 per cent of the total amount of fuel consumed.

*Note that this value does not apply to diesel engines, which typically consume significantly more oil than petrol engines. This is particularly true of the diesel engines of 20 years ago.

Let us look at a practical example of how this calculation works-

If we assume that a medium-sized to large passenger vehicle uses say, 8 litres of fuel per 100 kilometres in a combined cycle of urban and highway driving, the vehicle will use 80 litres of fuel per 1000 kilometres of driving. Thus-

Note that these values were generally true and accurate 20 years ago. They are no longer true even for some small, compact passenger vehicles; in fact, the above oil consumption rates are often exceeded by 100 per cent (or sometimes more) on many new engines in all vehicle categories.

In the real world, there is frequently nothing we can do about excessive oil consumption on new vehicles. Nonetheless, by performing the above calculation, we can reassure many owners of new vehicles, that the rate at which their engines consume oil is "normal"- even if it is normal only in terms of how the manufacturers of their vehicles define "normal".

One last thing on this topic, though. It should be borne in mind that even though we will soon be allowed to work on brand new vehicles, limited repairs to remedy excessive oil consumption issues typically produce limited results. For instance, since all of an engine’s components and systems contribute to high oil consumption rates, replacing only some parts (like the pistons and rings) will produce only a partial improvement. As a general rule, if you replace only ten per cent of an engine, that engine’s oil consumption rate will only see a 10 per cent improvement, which brings us to-

Note that while the few issues we will discuss in this section are among the most common ring failures across all applications, how soon each of these issues appears depends on the particular engine; how the vehicle is driven, and most importantly, how well the rings match both the cylinder bores’ shapes and surfaces in a given engine.

Other important factors include how closely the manufacturers’ recommended running-in procedure had been followed, and the quality of the fuel used. Note that this is a particularly important factor in the Australian context, given the poor quality of our fuel. Nonetheless, let us start by looking at-

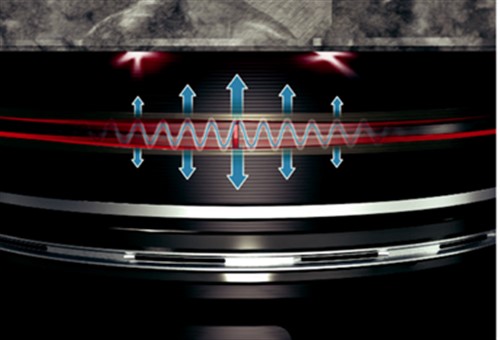

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

As shown here, axial ring flutter refers to a condition in which one or both compression rings start to "bounce" in their groove(s), thus interrupting the seal between the underside of the ring and the bottom surface of the ring groove(s).

Regardless of the cause, this condition destroys the radial contact pressure between the ring face(s) and the cylinder wall(s), which causes a severe loss of power, and a sharp increase in oil consumption at medium to high engine loads and speeds.

As a practical matter, axial ring flutter always starts at the ring ends (ring gap) because the ends of the ring are the least supported there. As shown above, the fluttering motion is biggest at the ring ends, and although the amplitude of the fluttering motion reduces as it spreads around the ring circumference, an entire ring can start to flutter or “bounce” up and down in its groove in cases where prolonged or frequent ring flutter had begun to increase the ring/groove clearance.

Causes of excessive axial flutter

Note that although thin rings have a reduced tendency to flutter due to the higher surface pressure they exert, rings with reduced heights are not entirely immune to fluttering. Below are some common causes of excessive axial flutter-

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

This condition occurs when a sudden increase in combustion pressure passes in between the ring face and the cylinder wall. As shown here, none of the combustion pressure enters the ring groove; instead, the excessive combustion pressure overcomes the ring's spring tension and lifts the ring face away from the cylinder wall. As a secondary effect, the excessive combustion pressure can lift the ring off the bottom of the ring groove. This causes the ring to flutter at one or more points around its circumference, as opposed to the ring bouncing up and down in its groove. The image below shows this phenomenon in action-

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

Causes of radial ring flutter

This condition can occur during the first start-up of new engines, which is why some new engines burn excessive amounts of oil from the moment they leave the showroom floor. Below are the most common causes of radial ring flutter-

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

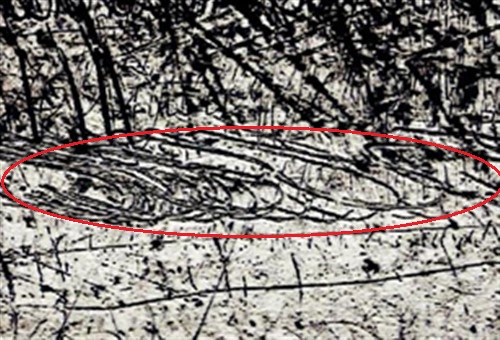

This image shows a small part of the face of a soft, uncoated cast iron ring that had been magnified 300 times. Note the swirling pattern of the scratches in the red oval; this is conclusive proof of one of two things, both of which occur more often than one might suppose.

In this example, the scratches were caused either by poor honing that left excessively large asperities on the surface of the cylinder wall, or just as likely, by dirt in the oil. Since this example was taken from a brand new engine, the solid particulate contaminants in the oil were almost certainly in the form of machining particles that were not cleaned out properly during one or more of the engines’ manufacturing/machining/finishing processes. Below is another example that shows even worse damage-

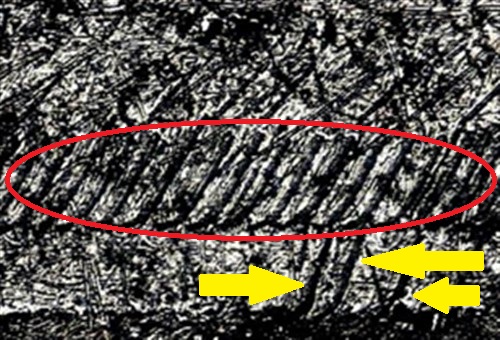

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

This example, which was also taken from a brand new engine, also shows the characteristic swirling pattern of scratches, but in this case, the yellow arrows indicate deep lateral gouges across the ring face that were caused by one or more contaminants that were harder than machining debris.

The most likely contaminant, in this case, is dust in the assembly environment, but regardless of the cause(s) of this type of ring damage, it should be obvious that rings in this condition cannot possibly be effective gas and oil seals. Sadly, though, this type of damage on uncoated rings is relatively common, and while using hard coatings on all rings is an effective remedy, the cost of coated rings often makes this an unattractive option for manufacturers.

Image source: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf

It is tempting to think that modern engines are assembled by robots that do not make mistakes. However, the fact is that in many markets, new engines are still assembled manually, and often by people who do not always understand the processes and/or the steps they are performing.

This image illustrates this point very clearly; it shows an area (in red) in the ring where excessive spreading of the ring during assembly had deformed the ring enough to allow both combustion gas and oil to escape through the deformation.

Worse, though- if this happens with a coated ring, the hard coating can, and often does flake off. In many cases, the flakes are ejected during engine operation. In other cases, though, the hard flakes can become embedded in either the piston or the cylinder wall (or in both) which, usually causes fatal damage to both the piston and the cylinder wall.

As a practical matter, the damage caused by the excessive spreading of rings is not immediately apparent during a visual inspection. Thus, since some plants assemble several hundred engines in a working day, many deformed piston rings make it out into the real world. Of course, this is not the same as saying that engine assemblers damage piston rings intentionally, but the pressure of installing rings on pistons in a fixed period, coupled with the lack of experience of some assemblers contribute to the frequency of these kinds of mistakes, which leaves us with this-

We hope that you have found the information in this series of articles helpful and informative and that they have given you some new insights into why piston-sealing systems fail so often and so badly on new engines.

On a purely practical level, though, it is generally not easy to determine the exact cause of excessive oil consumption on new engines without dismantling the engine. Despite that, though, when you are trying to figure out the possible causes, it helps to remember that although piston rings are always involved in excessive oil consumption issues, piston rings are rarely, if ever, the cause of the problem.

In fact, almost all oil consumption issues and ring failures can almost invariably be traced back to issues that cause rings to not work as they should, as opposed to simple ring failures that increase oil consumption. Thus, when piston rings fail, they fail as a result of one or more issues that affect their operation, which makes ring/piston replacements arguably the single most ineffective remedy for excessive oil consumption issues.

Therefore, unless the underlying causes that prevent the rings from working as intended are not addressed as an integral part of the diagnostic and repair process, the repair is neither complete nor reliable. Moreover, bear in mind that with these kinds of issues there are often no remedies available because the overall design of an engine is sometimes the actual problem.

Persuading irate customers that we cannot resolve their oil consumption issues is, of course, an entirely different matter, but that is a topic for another time.