If you are an experienced technician, you will no doubt have resolved driveability issues caused by restrictions in exhaust systems many times before. However, if you are a newly qualified technician you should know that since exhaust restrictions can cause driveability problems that can vary from slight to severe, it is sometimes easy to overlook a restriction in an exhaust system as the root cause of driveability concerns. Thus, in this article, we will take a closer look at how exhaust restrictions affect engine operation, how to diagnose restrictions in exhaust systems, and why some types of exhaust restrictions do not set fault codes. Let us start with revisiting-

It is easy to forget that much of the efficiency of modern engines is due to the way modern exhaust systems extract exhaust gas from engines. Although a piston on its exhaust stroke imparts the initial impetus to a slug of exhaust gas, it is the combination of engines’ firing order, the design and configuration of its exhaust manifold (relative to the firing order), and the relationship between an exhaust systems’ total length and average diameter that propels exhaust gas through the system.

More precisely though, it is the relationship between the total amount of friction a unit of exhaust gas experiences as it moves through the system, and the number of restrictions in the form of silencers and catalytic converters in the system that determines how well, or otherwise, the exhaust gas is scavenged from the cylinders. As a practical matter, each slug of exhaust gas that leaves a cylinder moves through the exhaust system more or less intact and in a fully functional exhaust system that is free of leaks and/or excessive restrictions, the exhaust stream will leave the exhaust system in a series of pulses, as opposed to a coherent stream of gas.

Therefore, for optimal exhaust scavenging to occur, the slugs of exhaust gas have to move through the exhaust system at equal distances from each other to create equally-spaced areas of lower pressure between them, which is the principal mechanism that "drags" or extracts each successive slug of exhaust gas from the cylinders through the exhaust manifold.

Restrictions in the form of silencers, balancing tubes, and catalytic converters are calculated not to disrupt the rhythmic flow of exhaust gas through the system and provided the pressure in the exhaust system does not exceed about 27.5 kPa, the volumetric efficiency of the engine is not affected in meaningful ways by built-in restrictions. Put in another way, this means that if an exhaust system operates as intended, a naturally aspirated engine will expel about 80% or so of the air it ingests through the exhaust system without generating exhaust backpressures that exceed about 27.5 kPa at any point in the exhaust system.

The above describes the basic theory of exhaust scavenging, and for the most part, the practice supports the theory tolerably well, even in standard OEM exhaust systems that contain several built-in components that impede the flow of exhaust gas through the system somewhat, which brings us to-

While the typical nature of exhaust system restrictions is largely irrelevant to the main topic of this article, the practical effects of exhaust restrictions and the symptoms they produce are not. For instance, a no-start, hard-start, or rough/erratic idling condition on a vehicle that is not fitted with exhaust pressure sensors* could be caused by any number of things, but even in the absence of air/fuel metering, ignition, and/or related electrical fault codes, the cause of the condition might not be immediately ascribed to a very dense exhaust restriction: think rodent nest, a collapsed/clogged silencer, or a partially melted catalytic converter core.

* Exhaust pressure sensor data can be a valuable diagnostic aid in locating exhaust restrictions.

The same thing is true for less-dense exhaust restrictions that typically produce varying degrees of power loss, misfires, increased fuel consumption, and/or higher-than-normal engine temperatures. While some of these and other symptoms may be relatable to “effect” trouble codes, there are often no fault codes present that point to exhaust restrictions directly; if there are trouble codes present, they are often either pending or historical, and their relationship(s) to observable current symptoms are therefore not always immediately relatable to possible exhaust restrictions, which begs the question of-

There are several ways of doing this, and while some produce more definitive results than others, we do not recommend that you disconnect the exhaust system from the exhaust manifold before taking the vehicle for a test drive. While this might prove the presence of an exhaust restriction because the vehicle will perform better, doing this might not only set a multitude of fault codes- driving a vehicle without a working exhaust system is illegal and could net you a hefty fine.

Levity aside though, one of the best ways to diagnose exhaust restrictions is to test drive the vehicle with a scan tool connected to record some important PID’s you will need to make a conclusive diagnosis without the need to dismantle the exhaust system piece-meal. Here is what you need to do-

As a first step in the diagnostic process, you need to know how well the engine “breathes”, but to do this you need to first collect some useful information during a test drive. If you have never calculated an engine’s volumetric before this, set a scan tool to record operating parameters such as RPM, MAF sensor data, engine load, oxygen sensor data under closed-loop operating conditions, and both short and long-term fuel trims under closed-loop operating conditions. Others could include the ambient temperature and barometric pressure because the object is to collect as much data as you can to calculate a volumetric efficiency value that is accurate as you can make it, but be sure to record at least two, but preferably three, WOT (Wide Open Throttle) events as well.

There are many volumetric efficiency calculators available online, but note that by itself, this value should not be considered as proof or evidence of anything* because an engines’ volumetric efficiency value is intended to serve as a screening test. An abnormally low value only tells you that the engine is not breathing well; a low value does not necessarily translate into an exhaust restriction, nor does a value above about 80% necessarily translate into an exhaust that is not restricted.

*Note that depending on a modified engine's state of tune, level of modification or means of induction, it is possible to have efficiency values well above 80% even with significant restrictions present in the exhaust system.

So what does this mean? It means that if you obtain a volumetric efficiency value of markedly less than about 80% on an unmodified, naturally-aspirated engine, you need to place this value into the context of the other engine operating parameters you’d recorded earlier. For instance, if the maximum airflow as recorded by the MAF sensor coincides with the maximum engine speed at the point(s) in the test drive where the throttle was wide open, the MAF sensor is good, and you need to dig a little deeper.

At this point, we need to consider oxygen sensor and fuel trim data, but if the MAF sensor is good and its highest measured airflow rate coincides with the maximum recorded engine speed at WOT events, you might notice something curious happening with the fuel trim values. If the exhaust is indeed restricted, you will notice almost-normal fuel trim values, although oxygen sensor data might show that the upstream sensors measured fully rich conditions at WOT, which might seem strange at first glance, but is in fact, expected behaviour. Here is why-

For our purposes, let us assume that the engine's volumetric efficiency is 70%, and the MAF sensor is good, based on recorded data. So, if the exhaust is restricted, the air flowing through the MAF sensor is still being reported accurately, and the fuel management system will deliver an amount of fuel per injection event that matches the intake airflow as reported by the MAF sensor.

However, because the exhaust system cannot expel the exhaust gas effectively, the air/fuel mixture will enrich itself as a consequence of the poor flow through the exhaust system, and the oxygen sensors will report the rich mixture correctly, even though the fuel trim values remain normal, or close to normal.Thus, the combination of almost-normal fuel trim values, a rich condition as reported by the oxygen sensors, and known-good MAF sensor data is clear evidence of a restricted exhaust, although neither the location nor the severity of the restriction can be easily deduced from this combination of factors.

However, there is another way of diagnosing exhaust restrictions that a) requires far less testing, and b), is not dependent on either the engines’ volumetric efficiency or MAF sensor data to be accurate. Here is how to diagnose exhaust restrictions-

Although theory states that the pressure in an engine cylinder should be equal to the pressure in the exhaust system when a piston is on its exhaust stroke, this is not entirely true. The pressure in the cylinder will always be slightly different to the pressure in the exhaust system during different phases of the exhaust stroke as the result of both the restriction(s) formed by the exhaust valve(s), and the oscillating patterns formed by pressure waves moving through the exhaust manifold and further along the exhaust system.

While these slight pressure differentials can be safely ignored if you are looking for exhaust restrictions, it is important to remember that a) such pressure differentials exist and, b), that their presence does not necessarily translate into an excessive or even a significant exhaust restriction. To illustrate this point, let us consider an example of an oscilloscope trace obtained with an in-cylinder pressure transducer that shows a pressure profile of exhaust gas entering a known-good exhaust system-

Image source: https://www.searchautoparts.com/sites/www.searchautoparts.com/files/images/Fig%205_1.png

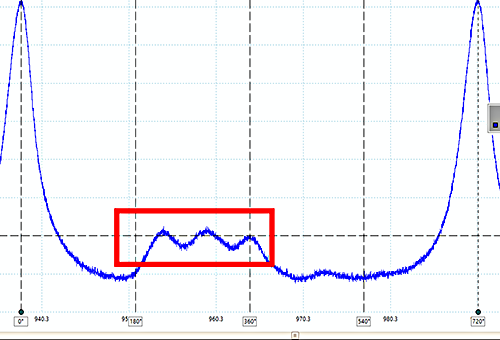

In this example, the first blue peak represents rising and falling combustion pressure, while the series of small-amplitude peaks in the red box represents fluctuating pressures during the exhaust stroke relative to the normal exhaust pressure, which is represented by the dotted line running length-wise through the red box. The most significant aspect of the small pressure fluctuations is that they are a) almost equally spaced, and b), that they have about the same amplitude, which is indicative of exhaust gas that flows unimpeded through the exhaust system.

Now let us consider an example of an exhaust system that is known to contain a significant restriction-

Image source: https://www.searchautoparts.com/sites/www.searchautoparts.com/files/images/Fig%207_0.png

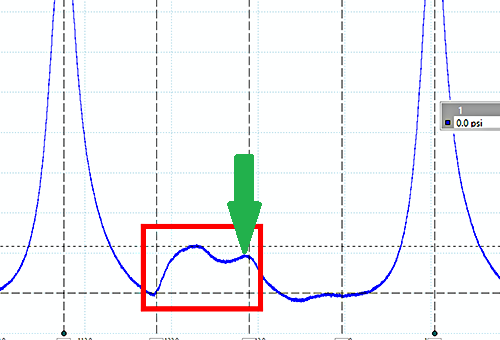

In this example, the waveform in the red box is also measured relative to the normal exhaust pressure, but in this case, the steep rise in the cylinder pressure is indicative of a slug of exhaust gas colliding with slow-moving exhaust gas that is trapped in the exhaust manifold. The shallow drop-off following the steep rise (green arrow) traces the speed at which the trapped exhaust gas in the system is being forced past the restriction, but note that the rise in pressure coincides with the beginning of the intake stroke.

In this case, meaningful amounts of exhaust gas may enter the cylinder through the intake valve during valve overlap, which as we know, can have serious negative effects on combustion. Typical results of this type of situation could include misfires and cylinder power contribution issues, both of which conditions can cause several trouble codes to be set.

Note that in both examples, the scope traces were captured while snapping the throttle open, and with a little practice, it becomes easier to deduce both the location and the severity of an exhaust restriction by analysing the exhaust stroke waveform, but that is not the primary objective of scoping exhaust system waveforms. The primary objective is to confirm or verify the existence of an exhaust restriction, or to eliminate an exhaust restriction being the root cause of driveability concerns, which brings us to why -

As experienced technicians, we know that catalytic converter efficiency issues usually revolve around clogged, damaged, or even partially melted catalytic convert cores that inhibit the free flow of exhaust gas through the exhaust system. We also know that catalyst efficiency issues usually, but not always, set either code P0420 –“Catalytic converter system, Bank 1 – efficiency below threshold” or, code P0430 – “Catalytic converter system, Bank 2 – efficiency below threshold”, so the question becomes one of why these codes do not always set when catalytic converters degrade or become sufficiently inefficient to form serious exhaust restrictions.

You may have come across instances of plugged/clogged catalytic converters where neither code was present, and if you were wondering how this was possible, here is how it works-

There are for the most part only two reasons why catalytic converters can fail without setting trouble codes; the first is that the ECU had disabled the catalyst monitor due to the presence of current and/or historical misfire codes, and the second is that the monitor enabling conditions have not been met for one reason or another.

In either or both these cases, the vehicle will continue to operate, but since the catalyst efficiency monitor cannot run, or is prevented from running by the ECU, the catalytic converter will continue to degrade without setting trouble codes, until it degrades to the point where it effectively blocks the exhaust system.

We only mention this scenario to remind you of the fact that the absence of catalytic converter efficiency codes does not necessarily translate into healthy catalytic converters, which means that all diagnostic procedures aimed at identifying exhaust restrictions must include the proper testing and/or assessment of the condition of all the catalytic converters on a vehicle, which brings us to this-

The proper operation of a modern exhaust system is as important to the overall efficiency of a modern engine as the operation of the intake system is. Therefore, any restriction in an exhaust system that raises the maximum allowable exhaust backpressure even marginally has the potential to cause significant reductions in a modern engine’s volumetric efficiency, which means that any repairs to exhaust systems or the correction of exhaust restrictions, must be verified by performing a proper test drive to confirm and verify that all engine operating parameters, including the engines’ volumetric efficiency, fall within acceptable, if not specified ranges.