Timing chain stretch is not actually the ‘stretching’ of the chain, it’s an elongation of the timing chain caused by wear in the chains components. The most common cause of this phenomenon is actually lack of maintenance and regular oil changes using a quality oil.

Contaminated and unserviceable oil loses its ability to lubricate the chain and causes the links and rollers to wear against each other. As the chain rolls across the gears of the cam and crankshafts, this movement between the links and rollers causes elongation.

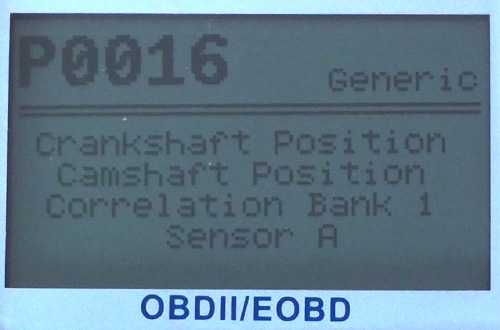

As the chain wears, this causes the timing of the cam and crankshaft to change resulting in poor running conditions as well as crank/camshaft sensor correlation fault codes.

If ignored, the timing chain eventually elongates to a point where then engine has a significant loss in power due to a lack in compression. In worse scenarios, the timing chain can actually skip a few teeth. There is also provision for contaminated and unserviceable engine oil to cause damage to the chain tensioner which increases the possibility of catastrophic engine failure.

One of the most notorious engines for timing chain elongation is the one you are thinking about, Holden's Alloytec V6 along with Fords Modular V8 and the Nissan VQ series V6. The manufacturers of each of these engines sighting insufficient oil changes as the cause of timing chain elongation.

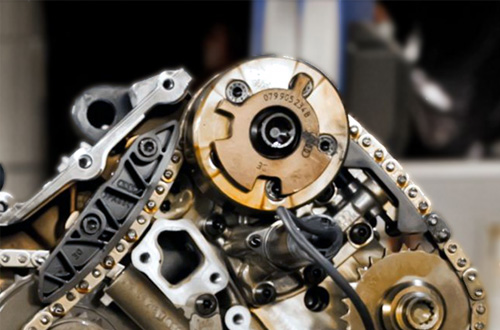

When it comes to replacing timing chains, it may be imperative to replace associated components such as the chain tensioner and variable valve timing actuators. After all they have been subjected to the same contaminated/unserviceable oil as the chain. There are precision machined surfaces and seals within most variable valve timing actuators that can be damaged by contaminated/unserviceable oil. Although initially more expensive, this practice eliminates the need for re-works or additional labour for your customer at a later date.

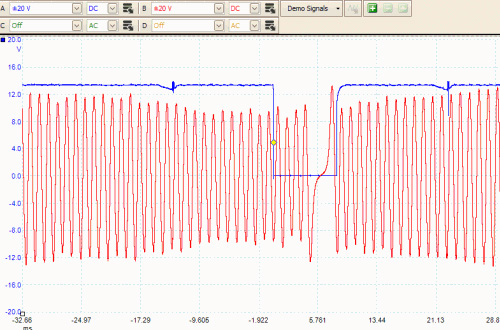

When diagnosing an elongated timing chain, it is almost impossible to access timing marks or references on modern engines. In most cases it is best to use an oscilloscope to check cam and crankshaft sensor correlation.